As organizations implement their technology strategy, they are learning that every element of the digital transformation triad is critical.

Digital transformation insights

- While many organizations have adopted new technologies and trained people accordingly, they often fail to update their maintenance and reliability processes.

- To fully benefit from condition monitoring and analytics tools, teams must eliminate outdated, redundant tasks and integrate their systems to drive efficient, data-informed decision-making.

- By modernizing maintenance procedures and encouraging collaboration between reliability and operations teams, organizations can extend asset life, optimize inventory and reallocate personnel to higher-value tasks.

One of the most common challenges process manufacturers face is getting the most value possible out of digital transformation initiatives. Most modern companies have added new technology as part of plant- or enterprise-wide digital transformations, and they likely see significant benefits from those changes. However, because nearly everyone has made some progress toward digital transformation, the bar to secure a competitive advantage has been raised. Ultimately, the most successful organizations — the ones for whom digital transformation delivers the most value — will be those that not only implement new technologies, but also drive a conscious effort to make the most of them to deliver the desired outcomes.

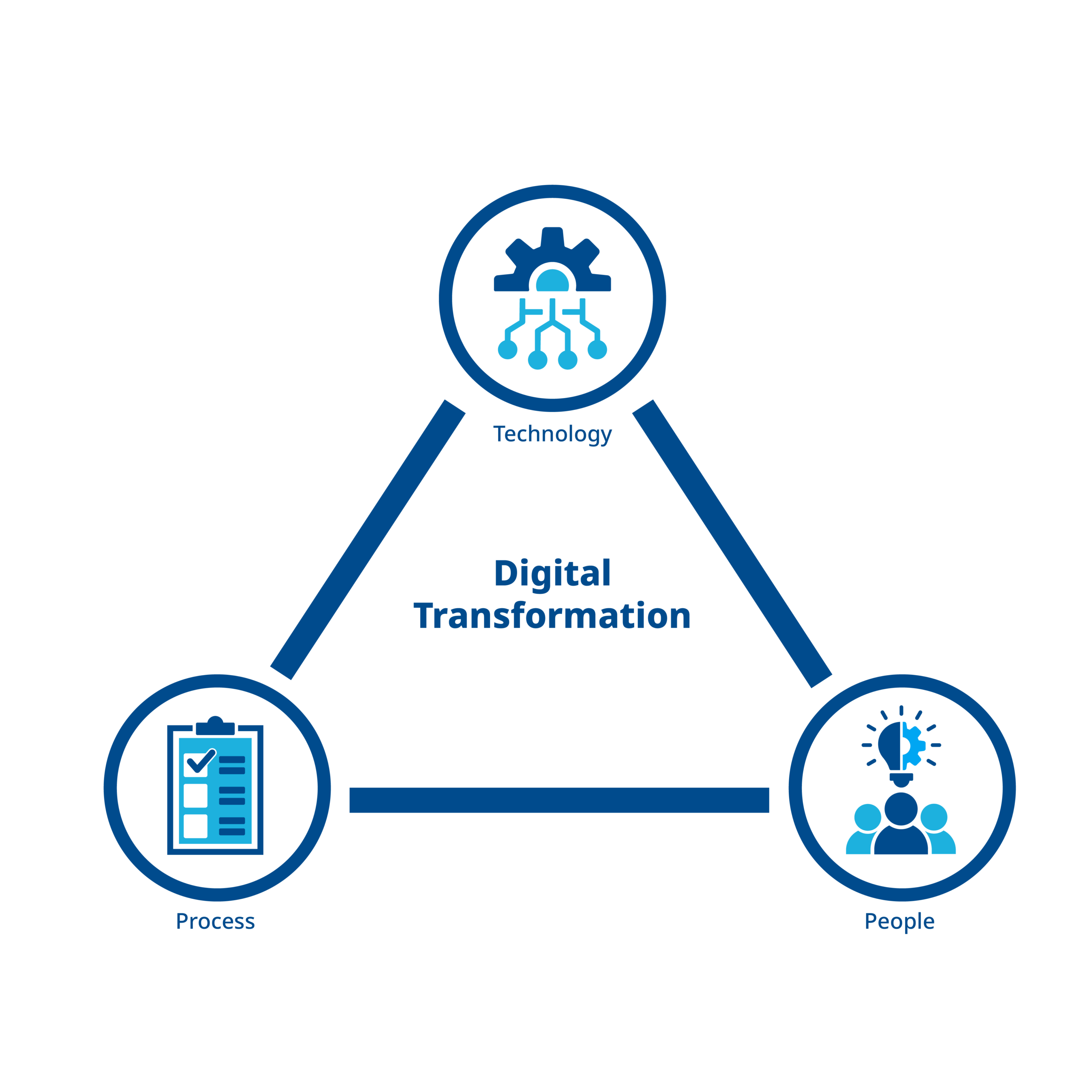

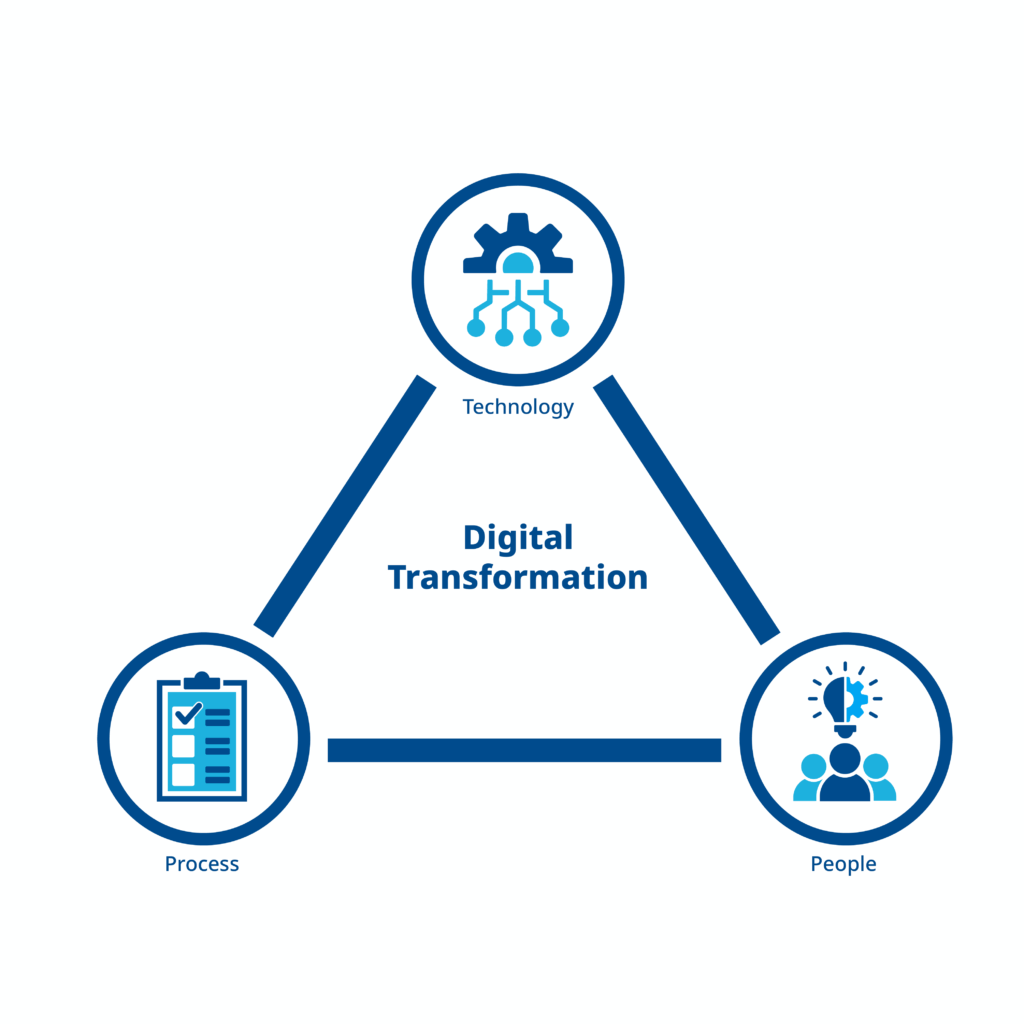

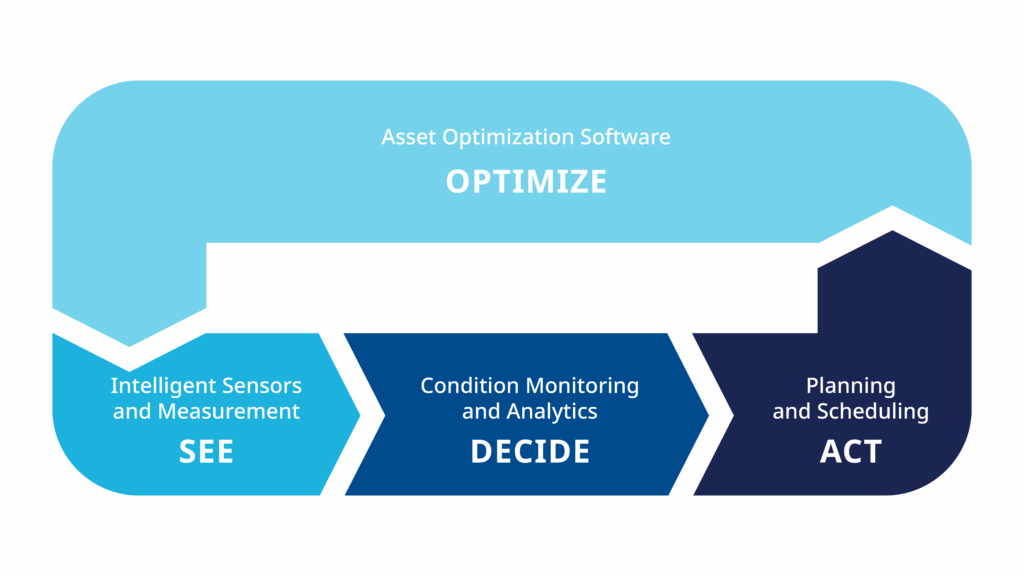

Making the most of both new and old investments means focusing on the key elements of the digital transformation triad: people, processes and technology. Doing so is not complex, but it does take concentrated effort and regular review to drive success (Figure 1).

Figure 1: All three elements of the digital transformation triad are essential to driving value from technology investments. Courtesy: Emerson

For most organizations, technology is the easy part. With each passing year, there are more options for sensors, analytics, compute resources and more. Similarly, preparing people for digital transformation has become easier in recent years. A generational shift has brought new, technologically savvy workers into the plant; a global pandemic normalized remote technologies, mobility and centralized operations and maintenance; and training has become commonplace as newer, less experienced personnel enter the workforce.

Managing processes, however, has proven to be more difficult. As many plants implement state-of-the-art technologies and train their people to use them, they often continue running their maintenance and reliability teams the same way they have for decades. With one element of the digital transformation triad supported less than the others, the foundation cannot hold, and teams will struggle to deliver the gains they anticipate and desire. Increasing effort into supporting process improvement is therefore critical to closing the loop on maintenance and reliability for companies wanting to stay competitive in an increasingly technological global marketplace.

Improving reliability processes

At the heart of improving reliability and maintenance processes is streamlining the workflows around condition monitoring. Reliability teams do not operate the same way they did just a decade ago. In most cases, plants have reduced the need for physical rounds, with wireless condition monitoring technologies serving as a replacement for many walkarounds. As a result, they have expanded access to critical data that can help teams identify problems quicker and easier.

Now that those tools are in place, teams need to find ways to make what they have more efficient. On the most basic level, that might mean eliminating the walkarounds that are no longer necessary. Old habits (or procedures) die hard, and just because a reliability team does not need to manually inspect each device on a regular cadence does not always mean they have stopped doing so. Whether teams implemented redundant data collection as a safety net while piloting new technologies, or because they never updated their standard operating procedures, now is the time to eliminate those overlapping activities.

To further improve maintenance processes, many organizations are implementing analytics software that integrates seamlessly with their computerized maintenance management system (CMMS) for increased efficiency. Analytics software provides deeper insights into the data collected through condition monitoring, and it can also examine that data in context of operations, providing a clearer view into the causes and effects of maintenance issues.

To get the most value from the data delivered by condition monitoring and analytics tools, reliability teams need to use that data to drive outcomes to execution. Seamlessly integrated systems built with a boundless automation vision for data mobility empower reliability personnel to push critical data directly back into the CMMS, with all relevant context and recommendations, simplifying and speeding the workflow for issue resolution. Reliability teams can also increase their effectiveness by collaborating directly with operations, providing contextualized asset health data to operators to help them understand how control decisions impact the longevity of the assets in their processes.

Improved reliability processes deliver results

In most cases, reliability teams that have not made an intentional effort to improve processes find that, even with all the analytics and condition monitoring they have installed, they have not removed enough traditional work from their plant. If the organization deploys condition monitoring technologies on the critical and essential assets in the plant but never removes or optimizes the schedule-based maintenance activities in the CMMS that are no longer relevant, the reliability team will struggle to identify — and, more importantly, demonstrate — the gains achieved as part of their digital transformation activities.

Process changes help teams ensure they are not over-maintaining their assets. For example, if a team implements a device management package with a snap-in for valve monitoring, they should adjust their valve maintenance practices to reflect the new data they have available. Rather than servicing every valve during a scheduled outage, the team can use valve health data to identify those in need of service and then perform the appropriate repairs on those valves alone.

Such a solution can also apply to calibration. Many of the most advanced device management solutions also support calibration activities, empowering teams to perform them on an as-needed basis rather than on a regular cadence. However, to take advantage of this benefit, teams must examine their current processes and update them to reflect the capabilities of their new technologies.

Furthermore, many teams can more easily work with operations to improve the life of their equipment — another potential benefit of improving maintenance processes. If the reliability team receives information quickly and regularly from continuous condition monitoring and analytics tools, they can provide feedback to the operations team to help them operate differently to extend asset life, but only if they adjust their processes to allow for such cross-team communication.

Moreover, even if the operations team needs to run an asset at a pace that creates issues faster, reliability teams can use their data and the knowledge gained from operations to ensure they have spare parts ready and better manage inventory. This can only happen if they design appropriate processes, rather than maintaining decades-old inventory procedures (Figure 2).

Figure 1: When teams close the loop on maintenance and reliability, they drive far more value from their digital transformation investments. Courtesy: Emerson

Building the roadmap for reliability

There is no wrong way to start the journey to develop better reliability processes. In most cases, it makes sense to find the activities that generate the highest levels of waste and work from there to develop an idea and vision for better procedures. Some teams focus on automating data collection while eliminating physical activities. Others start at visualization of alerts and alarms, tying the results back into the CMMS for faster issue resolution.

Regardless of the strategy, evolving processes to turn data into action is easiest when a team’s software solutions are seamlessly integrated. While not impossible, it is typically much more difficult to improve a system with disparate elements because teams must first engineer connections — or alternate transport methods — for data before they can be confident enough to change their practices. In contrast, seamlessly connected software ensures that data flows freely and with context, and it is always accessible from any point in the reliability system.

In with the new

Process is likely the last element of the digital transformation triad to change because habits are difficult to adjust. Experienced reliability teams maintain their traditional processes because they value the long history of success behind these activities. However, modern operations require increased efficiency, and those gains are hard to accomplish with traditional reliability process models — particularly if those traditional methods have been made redundant with modern technology.

Teams understanding and embracing this shift are finding they can easily modify their processes to free up personnel for more valuable, meaningful tasks around the plant, and even across the enterprise. Often, those new processes resonate across both reliability and operations, helping the whole organization unlock the efficiencies necessary to compete in the modern marketplace.

Erik Lindhjem serves as vice president and general manager of Emerson’s Reliability Solutions business. In this role since June 2021, Llindhjem is focused on driving digital transformation through plant asset management of automation assets and machinery that enables clients to reach top quartile performance.

KEYWORDS

Digital transformation, process improvement, reliability

CONSIDER THIS

Are your current maintenance and reliability processes aligned with the capabilities of your digital tools, or are you still operating with outdated procedures that limit the value of your technology investments?