Feedforward controls applied to a process, with limited, measurable disturbances, can keep the process variable close to the setpoint.

Traditional feedback control is a lot like running backwards. Without looking at the track ahead, a rear-facing runner must rely solely on views behind to determine where to go. While looking backward, the runner can stay in the lane only by adjusting the left-right position as the edge lines get closer. If the runner goes too quickly, it’s easy to end up well off course before a course correction is applied. (See Figure 1.)

Figure 1: Running backwards down a straightaway. Like a feedback-only controller, a rear-facing runner can only see the past location, but that’s usually enough to stay on course. Even without looking ahead, it is easy enough to observe proximity to the center of the lane and compensate for any slow drift to the left or right. A feedback-only controller has little difficulty keeping the process variable near a constant setpoint if slow drift is the only disturbance. Historical measurements of the process variable usually tell the controller all it needs to know when the control problem is this easy. Courtesy: Control Engineering

Industrial feedback controllers face the same challenge. To keep the controlled process at the desired temperature, pressure, flow rate, etc., a feedback-only controller must wait to see how it’s been doing, then correct its mistakes and look again. That’s generally not a random trial-and-error procedure. Even if the controller knows enough about the process’ behavior to make educated guesses about necessary corrections, those corrections always must be made after the fact.

So like a rear-facing runner, a feedback-only controller must proceed cautiously to avoid over- or under-correcting for past mistakes. This is especially true when the controller is designed with inaccurate or incomplete knowledge of the process’ behavior. If the controller can’t predict the future effects of its current control efforts, it has little choice but to act conservatively over a longer interval rather than aggressively over a shorter interval. (See Figure 2.)

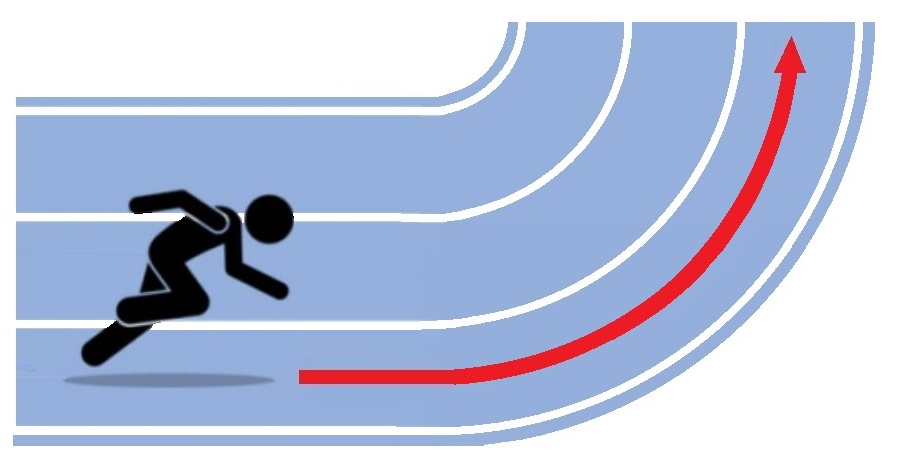

Figure 2: Running backwards around a curve is much more challenging. By the time the runner has noticed a curve has moved the center of the lane away from the runner’s path, the runner will already be off course. In the case shown here, the runner ends up too far to the left and then too far to his right while trying to compensate for the disturbance. High runner speed results in continued overcompensation back and forth until the disturbance ends at the end of the curve. A feedback-only controller will demonstrate the same oscillatory behavior if it was designed to act aggressively or if the controlled process turns out to be too responsive to the controller’s efforts. In the worst case, even an end to the disturbance won’t help. The controller might continue to oscillate between fully on and fully off as it continues to overcompensate again and again. Courtesy: Control Engineering

Look forward, not backward

The obvious solution to the runner’s dilemma is to turn around and look forward rather than backward during the run. With advance knowledge of upcoming curves, a front-facing runner will be able to make much more informed course corrections and will be able to run much faster.

An observant runner also can look down the track and take preemptive actions to stay in the middle of the lane when an upcoming curve is seen. The runner can start turning to the left exactly when needed, as shown in the “Running forwards” graphic, Figure 3.

Figure 3: Running forward down a straightaway is easy. With a view of the track ahead, the runner can compensate almost instantaneously to any slow drift to the left or right, even when sprinting at top speed. In much the same way, a feedforward controller applied to a process with limited, measurable disturbances can keep the process variable close to the setpoint easily enough.

Running forward around a curve is not all that much more difficult. The runner can visually measure any impending disturbances (curves), anticipate the effect on future trajectory, and make course corrections as needed rather than afterwards. Advance knowledge allows a front-facing runner to round a curve much faster and with much less error than a rear-facing runner can.

Advance knowledge allows a feedforward controller to be more aggressive and more accurate. If the controller can correctly predict how a disturbance is going to affect the process variable and how to compensate for it, the controller can afford to apply more assertive control efforts. Doing so can reduce the effects of an impending disturbance just as a runner can stay right in the center of the lane when anticipating upcoming curves. Courtesy: Control Engineering

A process controller equipped with sensors capable of measuring precursors to upcoming disturbances can operate faster and preemptively. There is no need to wait for the results of past control efforts to appear in measurements. Sensors and controllers work together to observe coming disturbances and feed the information forward to help calculate future control efforts.

Feedforward control example

A classic application of feedforward control is a steam distribution system where a central boiler provides steam at a constant pressure to various pieces of equipment throughout the plant. When an idle machine comes online and starts drawing steam from the boiler, the pressure controller can preemptively turn up the heat and inject additional water into the boiler, provided the system can determine how much steam the machine needs.

If the controller relied strictly on feedback, it would have to wait until the pressure in the boiler had already dropped before attempting to compensate for the additional load. If it can anticipate the upcoming disturbance, the pressure controller will be able to proactively prevent the pressure drop a feedback-only controller would need to see before taking action.

The trick to effective feedforward control is measuring indicators of upcoming disturbances and accurately predict the effects they’re about to have on the process variable. A front-facing runner hardly needs to think about what to do when there is a curve ahead, but a feedforward pressure controller would have to make less obvious decisions. It would need to know not only when a particular machine is about to come on-line, but how much steam it’s going to be drawing and exactly how that draw-down is going to affect the boiler pressure over time.

These predictions are often made with the help of a mathematical model that shows how the process responds to measurable disturbances. These models can be as simple as look-up tables containing the effects of disturbances measured in earlier tests or as complicated as multi-variable differential equations based on first principles analysis or empirical observations. On-line learning algorithms and other forms of artificial intelligence can sometimes help create – or at least refine – the mathematical model over time.

Best of feedback, feedforward

Since no model can be 100 percent accurate, and because other unmeasurable disturbances are likely to affect the process variable as well, a feedforward controller is almost always combined with a feedback controller. The feedforward controller makes its best guess as to the control effort required to compensate for an impending disturbance, and the feedback controller takes up the slack. The feedback controller measures the net effect of the disturbance and the feedforward control efforts then compensates for any deviations in the process variable the feedforward controller was unable to prevent.

Feedforward controllers can be difficult to implement. Feedforward controller design is challenging when the process’ behavior is not well understood, the disturbance variables are hard to measure, or there are too many disturbance variables to account for. A poorly-designed feedforward controller can sometimes amplify the effects of a disturbance and make the feedback controller’s job more difficult.

Less energy, less wear

A feedforward controller can be well worth the effort if disturbances are so frequent or so large that a feedback controller alone can’t keep up. A successful feedforward controller can reduce the effects of major disturbances to mere blips in the process variable. If doing so also eliminates the oscillatory behavior of a feedback-only controller, a combined feedforward/feedback controller will use less energy by making fewer control moves. Fewer control moves also reduces wear and tear on the actuator used to apply the controller’s output to the process.

Control Engineering tutorial edited by Chris Vavra, [email protected]; and Mark T. Hoske, [email protected], CFE Media.

MORE ANSWERS

Keywords: Advanced control, feedforward control, feedback control

A feedback-only controller looking backward must proceed cautiously to avoid over- or under-correcting for past mistakes.

Feedforward control can operate faster and preemptively and doesn’t need to wait for the results of past control efforts.

Effective feedforward control measures upcoming disturbances and accurately predicts what effects they’re about to have on the process variable.

Consider this

What benefits can an application derive from feedforward control?