Edge control can take many forms to access stranded data, with modern programmable logic controllers (PLCs) often the preferred alternative.

Learning Objectives

- Modern PLCs can act as practical Internet of Things (IoT) platforms, while still performing as an edge controller.

- Many edge devices use message queuing telemetry transport (MQTT) to transmit data.

- Edge control is best fulfilled by using PLCs that can support IoT initiatives right out of the box.

For as long as operators have interacted with machinery and equipment, the concepts of the industrial “edge” and “edge control” have existed. Control at the edge could be an operator’s manual interaction with the equipment, or it could be hardwired controls performing some required functionality. A more sophisticated arrangement could consist of digital automation, usually with a programmable logic controller (PLC) monitoring input sensors at the edge, processing logic, and commanding outputs to control edge devices.

Updated technologies lower edge control costs

If the concept of edge control is so familiar, then why is it gaining newfound attention? The answer is traditional edge control has often been quite remote and isolated, and it was expensive and complex to connect edge assets to each other or to higher-level systems.

Today’s concept of edge control maintains all the robust automation functionality of previous technology generations – while incorporating modern hardware, software, and networking advances – making it economical and easy to connect edge assets to on-site and cloud-based systems. This ready access to edge data is often described as an Internet of Things (IoT) implementation.

Smart sensors, modern PLCs and advanced edge controllers or PC-based platforms are among the ways designers can incorporate IoT concepts into their systems. PLCs with IoT capabilities help automation system designers and end users access data more easily.

Connectivity for sensors, machine information

Complete connectivity is important to users as they recognize the need to access data available from edge control systems. This data can be sensor signals, derived machine information, or other values—and it may be used just for simple remote visualization. But more operational value is unlocked when the data can be stored and analyzed, often via cloud-based computing, so users can take action to optimize operations.

For new industrial projects, it is becoming mandatory for designers to select automation platforms with built-in IoT connectivity, even if they will not immediately use it. Some end users also are investing to upgrade existing assets to gain IoT capabilities.

Designers might consider incorporating PC hardware and software, or more specialized edge controllers with some general-purpose computing ability, to create an IoT-enabled system. These options offer a higher level of computing power and capability, but they can be quite a step change in cost and effort required for implementing them. In many cases, this may not be warranted.

This is why modern PLCs often occupy the sweet spot for automation devices able to act as practical IoT platforms, while still performing as edge controller. As an established and familiar automation technology, PLCs are already the go-to solution for most industrial automation projects. PLCs also are ideally positioned to access, consolidate and transmit edge data. Because they are controllers, they can do more than just move the data. They also can act on it directly or send data to and receive direction from higher-level systems. A few key features transform PLCs into IoT-capable edge controllers.

Five IIoT edge functions for PLCs

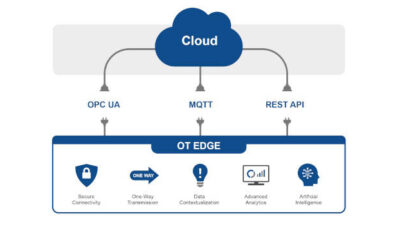

Modern PLCs are positioned for edge installation, which is where they can gather the most useful information (Figure 1). A PLC can fulfill the edge controller role when it includes the following features:

- Field and network connectivity

- On board data logging to support store and forward operations

- Web server functionality

- Support for cloud-capable communications protocols, like message queuing telemetry transport (MQTT)

- Simple configuration to support two-way communications based on these protocols.

Even the most basic PLC is capable of interacting with field devices via wired input/output (I/O) signals. Most of today’s PLCs also incorporate serial and Ethernet connectivity, which provides the ability to interface to a wide variety of intelligent field devices.

Beyond those fundamentals, a PLC intended for the edge control role should include industrial network protocols such as EtherNet/IP, Modbus TCP and RTU, and BACnet/IP to ensure it can communicate with the widest range of I/O systems and other intelligent edge devices. More specialized protocols such as SAE J1939 [Society of Automotive Engineers] Serial Control and Communications Heavy Duty Vehicle Network make the PLC suitable for vehicles and heavy equipment.

Certain features can make it easier for users to interact with PLCs. For example, local wireless Bluetooth connectivity, along with convenient configuration and monitoring using mobile apps, makes it convenient for users to access, monitor, and adjust modern PLCs. On-board data logging, web server functions, and file transfer protocol (FTP) communications give users many options for remotely accessing information.

A cornerstone of edge controller functionality is the ability to transmit data over the network and/or internet to site-located or cloud-hosted systems. There are various communications protocols for this, but the manufacturing industry has adopted the MQTT protocol for this task.

MQTT as an enabler for industrial communications

Traditional industrial communications protocols were often of the poll-and-respond variety, where users needed to carefully arrange data arrays in the source and destination. The destination polled the source, which responded with the raw data, which was then managed by the destination in terms of scaling and tagging. Setting up and maintaining such configurations required significant programming management, and time-based polling consumed communications resources regardless of whether the underlying data changed.

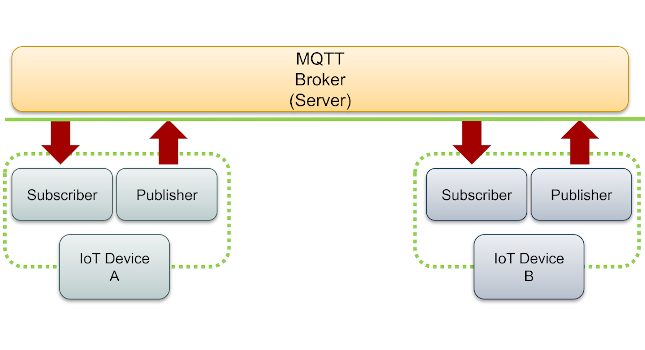

MQTT uses a different arrangement called publish-and-subscribe, which is well-suited for IoT applications (Figure 2). In this architecture, there is a centralized broker, which may be on-site or cloud-hosted, and there are one or more remotely located clients. Users can create the broker in many ways. Example clients are PLCs, smart sensors and mobile devices. Each client can be a publisher which sends data to the broker, or a subscriber, which obtains data from the broker, or both.

Designers still must configure the data of interest, but there are provisions in the protocol for establishing a hierarchy of the data, along with context such as tagnames and descriptions, improving usability and reducing required management effort for the information. Furthermore, MQTT uses outbound communications which are generally allowed by firewalls, and therefore avoid the need for IT support.

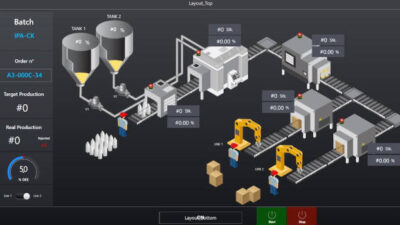

While many smart instruments which support MQTT are becoming available, and MQTT is a good option for more complex edge controllers and PCs, PLCs supporting MQTT are ideal for many automation applications (Figure 3).

This is because PLCs are familiar and already used for automating machinery and processes. PLCs are connected to or create much of the most interesting data sources for automated systems and are ideal to act as MQTT publishers. PLCs can be configured as MQTT subscribers to receive data from supervisory systems and execute user commands and directly control field equipment.

PLCs as the best-fit edge controller

Original equipment manufacturers (OEMs) for industrial machinery are moving to MQTT-capable PLCs for many reasons. These OEMs already use PLCs for many machine automation needs, so it is a small step from technical and cost standpoints to specify MQTT-enabled PLCs and future-proof such systems.

These OEMs have specific business needs which make adoption of IoT desirable. Many are leasing machines and need to monitor machine functionality and usage. Some OEMs are even basing lease values on uptime or machine production, or they may take advantage of remote connectivity to sell additional support services or consumable parts.

Whatever the need, these OEMs need an affordable option that fits with business models and skillsets. Integrating a PC-based or relatively complex edge controller device for small- and medium-sized systems is often not realistic.

For many users, edge control is best fulfilled by using PLCs that can support IoT initiatives right out of the box. PLCs with support for MQTT, combined with cloud services such as AWS IoT Core, help merge modern practices with traditional automation to deliver optimal results.

Don Pham is senior product marketing manager at Idec Corp. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, [email protected].

MORE ANSWERS

Keywords: edge computing, message queuing telemetry transport (MQTT), programmable logic controller (PLC)

CONSIDER THIS

What benefits could your facility gain from edge computing and edge devices?