Base-layer advanced process control provides new capabilities.

Base-layer APC, APC 2.0 insights

- Learn the new capabilities and opportunities that come with base-layer APC.

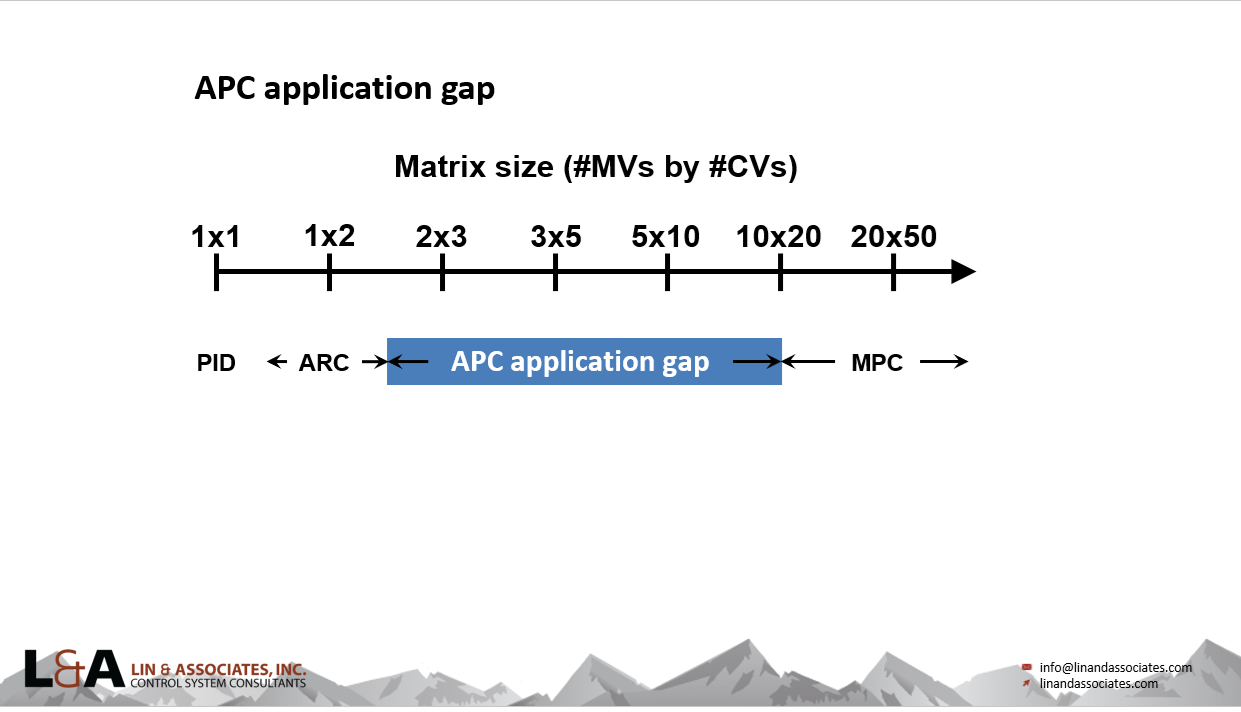

- Learn about the APC application gap.

- See why the best days of APC may be yet to come.

In the old days, the idea of base-layer advanced process control (APC) would have been an oxymoron. In those days, APC usually meant something deployed in the supervisory control layer. But nowadays, APC usually means multivariable control and optimization, and now it can often be deployed right in the base-layer. This brings some important new capabilities and benefits.

Base-layer APC basically refers to running multivariable control and optimization directly in the basic process control system (BPCS) layer, that is in the distributed control system (DCS) controller or in a programmable logic controller (PLC). These controllers are typically fault tolerant and have effectively 100% uptime. And they have execution frequencies on the order of seconds, not minutes, which can make all the difference in many applications. Speed and reliability are just two of several advantages of base-layer APC.

To fit an APC application in a base-layer controller, it needs to have a much smaller footprint and less resource consumption (memory and CPU) than conventional multivariable control. The decades of experience of APC 1.0 have revealed many lessons and shed much light on the essential nature of multivariable control and optimization. From this, modern APC companies are finding novel and more efficient methods to do APC that meet this these more limited resource criteria, while maintaining high performance and enhancing owner-friendliness.

The APC application gap

Of course, there is a limit to how much multivariable control can be accomplished in a DCS or PLC time slice. As an example, one base-layer APC tool on the market today accommodates applications up to 20 variables (number of MVs plus number of CVs). This is smaller than many traditional APC 1.0 applications that often numbered in the dozens or even hundreds of variables.

But this smaller matrix size may actually be more appropriate going forward in APC 2.0. Large matrix designs became the norm under APC 1.0 because the high cost and complexity favored economies of scale and “big envelope” matrix designs. In contrast, when operating teams carry out manual multivariable control, they typically need to consider only a handful of variables, not dozens or hundreds. This can render APC more compact, reliable and intuitive. A controller that accommodates 5, 10 or 20 variables may actually be the right size for many applications.

This range of applications – less than about 20 variables – has largely been overlooked and underserved by APC 1.0, so it is sometimes referred to as the APC application gap (Figure 1). Base-layer APC is a tool that fills this gap. Loop intervention analysis often reveals that many multivariable control applications in this range remain unaddressed after decades of APC 1.0. It could be that the best and biggest days of APC and new levels of successful process automation and optimization are yet to come.

Base-layer APC advantages

Base-layer APC brings with it several new capabilities and advantages. Base-layer APC has naturally high availability (essentially 100%), just like all base-layer controls. It also has (relatively speaking) lightning-fast execution speed, such as 2-5 seconds. This overcomes multiple vulnerabilities that have historically undermined APC 1.0 performance stemming from its typical 30- or 60-second execution speed.

Most cybersecurity, operating system update, control system software update and backward compatibility issues naturally go away when deploying APC at the base layer rather than the supervisory level.

Base-layer APC basically implies a function block deployment within the normal engineering environment of most modern control systems. This means that deployment, support, troubleshooting, graphics and nearly every other aspect of ownership, fall naturally under existing site control system support capabilities and resources, while reducing dependency on off-site resources.

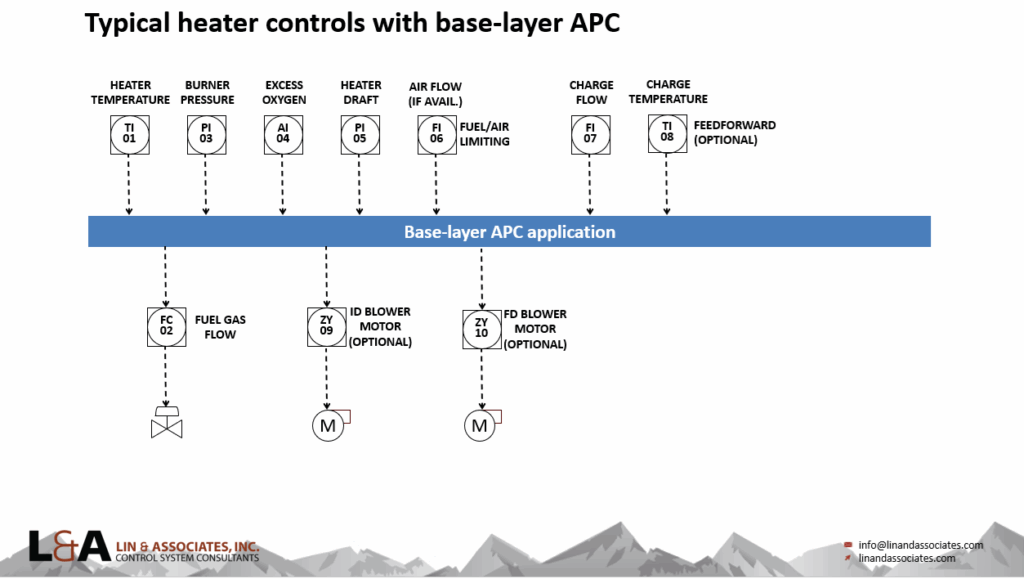

Figure 2 is an example of a fired heater base-layer APC 2.0 application. It combines combustion control, burner pressure overrides, draft control and oxygen control, in one high-speed / high availability base-layer multivariable controller. Under APC 1.0, heater controls typically required a relatively clumsy, complicated and less reliable combination of base-layer controls, overrides and supervisory level APC. Pass balancing could be added into Figure 2, or it could be implemented as a separate base-layer APC application function block.

Allan Kern, P.E., is principal APC consultant with Lin & Associates Inc. Edited by Mark T. Hoske, editor-in-chief, Control Engineering, WTWH Media, [email protected].

KEYWORDS

Advanced process control, APC 2.0

CONSIDER THIS

If you’ve held back applying APC software, is it time to reconsider?

ONLINE

Manual multivariable control

Loop intervention analysis