Schneider Electric demonstrates how the hardware agnostic distributed intelligence of its EcoStruxure Automation Expert platform is creating a flexible control architecture for manufacturers.

Earlier this month, Schneider Electric invited Control Engineering to tour its new Houston Innovation Hub to demonstrate its EcoStruxure Automation Expert platform and share details of recent customer deployments.

The event highlighted how open, software-defined automation can make engineering systems more flexible with modular equipment integration and help prepare the workforce for evolving demands.

Executives showcased the growth of its industrial automation business, sharing how Automation Expert has over 500 deployments. A key customer is Shell Oil Co., which has updated existing refinery control systems at its Scotford plant in Alberta, Canada with the hardware-agnostic open architecture.

“With Automation Expert, Schneider Electric has launched the world’s first open, software-defined automation,” said Ali Haj Fraj, Schneider’s senior vice president of digital factory.“We think this is a huge revolution in the market, bringing a lot of big values for our customers: hardware agnosticity, distributed intelligence, application centricity and digital continuity.”

Schneider’s industrial automation strategy

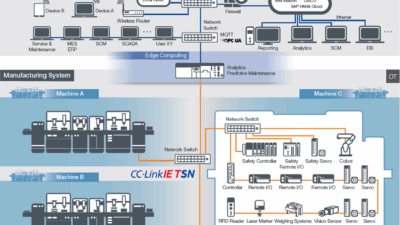

The Automation Expert platform is part of Schneider’s larger industrial automation business and is tailored to four markets: smart industries, equipment and machinery, infrastructure and grids and data centers.

“This is a very consistent, very simple platform, which connects all of our products in the first layer, then the second layer with edge control, and the third layer is software,” said Haj Fraj.

Within this framework, Automation Expert serves as a unified platform that ties Schneider’s products together and can integrate with third-party systems.

Why open automation matters for control engineers

Engineers face pressure to modernize aging systems, integrate new technologies, and manage with fewer resources. Executives presented how open, software-defined automation is more than just another technological shift – rather a strategic response to those challenges.

“Automation is not just an enabler. It’s a strategic imperative, building on the backbone for the progress of the industry,” said Haj Fraj.

A core feature of Automation Expert is that it’s hardware-agnostic, able to run logic on different devices. This allows engineers to swap hardware without re-engineering entire systems, helping them modernize faster while avoiding vendor lock-in. Haj Fraj says this decoupling approach “opens a huge door of having the two life cycles independent from each other.”

The platform also works with the runtime execution engine from Universal Automation (UAO), a non-profit association founded in 2021. Ravindra Jagasia, UAO’s Americas representative, said membership has grown from nine to 113 organizations, representing OEMs, integrators, startups, universities and end users. Together, they promote a shared runtime execution engine based on the IEC 61499 standard for automation applications.

“UAO actually started based off our experience on the shortages and supply chain issues immediately after COVID,” said Jagasia, noting that engineers often couldn’t begin software development until specific hardware arrived.

Automation Expert simplifies integration and hardware choices to prepare the workforce for tomorrow’s challenges.

“We’re really trying to bring the next generation of industrial automation into the now,” said Brett Redmond, head of product management for EcoStruxure Automation Expert.

Workforce skills and digital training shifts

Workforce shortages are reshaping how companies train and attract younger engineers, as Haj Fraj noted, the industry is “expected to be short of more than eight million talents by 2030.”

Jagasia emphasized this point, adding that many experienced engineers are set to retire and take “tribal knowledge” with them, so recruiting and developing younger talent is critical.

“You need an element of hiring and retaining new talent. You need people who can relate to these technologies,” he said, emphasizing the shift toward remote and digital problem solving.

Younger engineers share this expectation in their training.“They are not going to use something that cannot be explained in more than a one-minute YouTube video,” said Sophie Borgne, water and environment segment president for Schneider Electric. “They are not going to learn a specific language for automation. They want to be able to use what they script on a daily basis.”

Verdi Wahjosoedibjo, Shell’s global discipline head for instrumentation, control, and electrical, echoed this trend. He noted a shift from traditional manuals to digital and artificial intelligence (AI) driven problem solving.

“We want to embrace more digitalization, more AI,” he said, adding that companies can’t ignore these technologies, or they’ll risk being “left behind.”

Shell Scotford modernizes controls with open architecture

Building on the workforce and digitalization trends, Shell deployed Automation Expert in 2021 to modernize key control processes at its Scotford plant.

The process started by transitioning away from legacy programmable logic controllers (PLCs) to open architecture systems and included two air dryer applications using function block programming and OPC Unified Architecture communication.

Chris Seppala, Shell’s principal technical expert for base layer control, modeling, and optimization, worked directly with the team for this change. He reported that employees said the process was faster to implement than traditional ladder logic programming.

Building on this progress, Shell deployed a filter press application in 2023 and continued its use of the hardware-independent approach.

“We are supporters of open architecture,” said Seppala. “Because at a leadership level, we recognize the importance of this as the automation landscape shifts.”

This approach is part of Shell’s vision to build more flexible systems with third-party components. Currently, it’s working on a proof of concept for hydrocracker reactor warm-up procedural automation.

“If we can prove that this is a really successful and easy-to-use way to implement automated procedures, we have a ton of applications all over the company, without having to take out the existing automation systems,” said Seppala.

City of Conroe deploys remote monitoring for water plants

Beyond industrial plants, Automation Expert is also helping municipalities manage infrastructure, including the City of Conroe, Texas, which operates over 53,000 service connections to provide water to a population of over 110,000 people. Conroe implemented the platform to provide remote monitoring and digital integration.

Daniel Roberts, the city’s water superintendent, recalled life before automation, when the customers themselves were the first to alert when problems occurred. The partnership with Schneider has eliminated that issue.

“The EcoStruxure Automation Expert equipment has given us remote control of these water facilities, and that should allow us in the future to be alarmed and give us time to fix any issues before the customer is impacted,” said Roberts.

The integration includes distributed intelligence in drives, embedded logic at each pump, and manual override panels as backup. Workers now use tablets to monitor sites in real time, helping them detect leaks or failures sooner and reduce water waste.

Future of open automation: modular design and AI

At the Houston Innovation Hub, Redmond described the next stage for EcoStruxure Automation Expert, which combines modular design, digital continuity and AI.

He described reusable software objects as “digital Lego bricks” that engineers can copy and redeploy across projects, adding that linking design files directly to control logic and human-machine interfaces (HMI) can shorten project cycles.

Redmond added that generative AI can take a control narrative, combine it with object-oriented assets to show the interaction and generate the system configuration. While engineers will still need to validate results, the digital tool can reduce manual tasks.

Reflecting on what’s next for industrial automation, Richella Odebrecht, Schneider’s senior vice president and chief marketing officer, used a NASA metaphor to illustrate the journey ahead.“Definitely lift off. But we’re past the first stage, so we’ve taken off,” she said. “We’re heading towards orbit.”

Pictured from left to right: Schneider Electric’s Richella Odebrecht, senior vice president and chief marketing officer, Marc Fromager, senior vice president commercial and segment industrial automation, Sophie Borne, water and environment president, Shell Oil Co.’s Verdi Wahjosoedibjo, global discipline head instrumentation, control and electrical, and Ravindra Jagasia, UAO’s Americas representative. Source: Sarah Wynn