Single-pair Ethernet (SPE) can help the Industrial Internet of Things (IIoT) drive industrial automation forward and manufacturers can benefit.

In an industry that applauds the wringing out of tiny inefficiencies from the production line in order to gain microscopic boosts in productivity, there is one culprit adding undetected weight and drag to the process – traditional ethernet solutions.

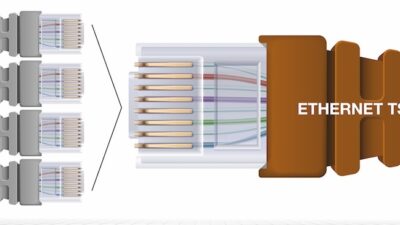

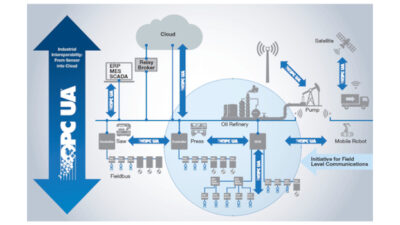

Rollouts of industrial automation systems today are built out of different styles of networks, each with a different communication standard attached to it. Because there are many different standards across networks, gateways are required to help translate those communications to enable machines to seamlessly exchange information. All these gateways and different communications standards add bulk to the production process. Single-pair Ethernet (SPE) enables machines to communicate without the extra layers.

Talking the same language

SPE technology is designed so all machines can talk in the same language, eliminating the need for translation between the various communication standards in the older network styles. It offers one network with one Ethernet communication language that all machines can understand and use.

In addition to improved efficiency SPE can reduce complexity and costs, allows more flexibility in designs and offers a scalable foundation to go beyond previous limited speed and interoperability.

While SPE has been in use in the high-volume environment of the automotive industry – where space saving, high performance and shared weight solutions are especially valuable – it is relatively new to the industrial space. However, its benefits are quickly proving obvious right across the industrial automation sector and in the Industrial Internet of Things (IIoT). Both require increasingly complex systems yet are built on an outdated legacy of multiple communication standards.

SPE enables cross-network real-time communication without any loss in information. This helps industrial engineers to build more streamlined, unified automation ecosystems that are more cost-effective than traditional Ethernet solutions.

The industry is now at a tipping point, with an exponential increase in innovation and technology just around the corner. The ‘smart tech’ trends that already dominate our personal lives are now focusing in on industrial automation and the IIoT.

These types of smart solutions will come to the industrial market and SPE will help in accelerating this trend because it enables underlying communications to take place seamlessly from machine-to-machine and from machine-to-human.

SPE benefits include:

- Allowing barrier-free communication from the sensor to the cloud.

- Providing movement freedom to applications.

- Making miniaturization possible with power over data line (PoDL) and hybrid connector solutions (high power single wire).

- Facilitating an open ecosystem.

- Allowing real-time, high-speed communication connections up to 1gb/sec and cable length up to 1,000m for 10mb/sec.

The possibilities of real-time, high-speed and secure ethernet communication are many. The best way to prepare for increasing customer demands tomorrow is to embrace SPE today.

This article originally appeared on Control Engineering Europe’s website. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media, [email protected].