Seven steps to a smarter factory: Automation vendors want to gain a competitive advantage with the Industrial Internet of Things (IIoT) and Industry 4.0. Ethernet with time-sensitive networking (TSN) helps.

Learning Objectives

- Ethernet with time-sensitive networking (TSN) is a way manufacturers are improving facilities and making them more connected.

- The technology landscape surrounding TSN is continuing to evolve as the Industrial Internet of Things (IIoT) and Industry 4.0 take hold.

- CC-Link IE TSN can help manufacturers achieve a better Smart Factory with improved performance, intelligence and connectivity.

Manufacturers are looking to automation vendors to deliver systems and technologies that will help them create connected industries, smart factories and integration with Industry 4.0 and the Industrial Internet of Things (IIoT). Automation vendors are looking for the latest technology that will give them a competitive advantage, such as improved scalability, performance, reliability, ease of use and increased cost effectiveness. One technology helping create improvements across the board is Ethernet with time-sensitive networking (TSN).

To achieve a global Smart Factory, the seven key areas to consider are:

- Ensure consistent quality and performance across global operations

- Balance manufacturing with demand to optimize material usage and asset utilization

- Improve and meet regulatory compliance

- Implement more flexible and agile manufacturing operations to respond to changing market conditions

- Meet demanding requirements and metrics for on-time delivery through reduced mean time to repair (MTTR) and increased overall equipment effectiveness (OEE)

- Reduce the cost of design, deployment and support of manufacturing and information technology (IT) systems at global manufacturing plants

- Improve response to events that occur on the plant floor regardless of their location.

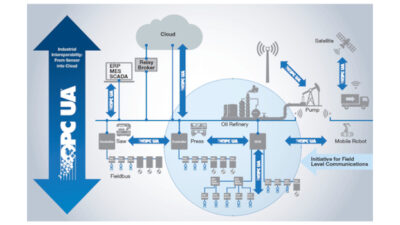

Combating ‘islands’ of automation

A major obstacle was existing industrial network systems’ inability to share information between different technologies. This led to data “islands,” which prevented information from being shared. Manufacturers of industrial automation control systems (IACSs) and their customers understand the value of the data produced in their factories and require seamless access to the data to make smarter decisions to run the factory in the IIoT and Industry 4.0 era.

Hence the kind of transparency required by Industry 4.0 applications is becoming the preferred approach. Taking terabytes of data from the shop floor to make useful information is part of the strategy. Data intelligence also can solve customers’ problems with a complete solution-based architecture focused on IT/OT convergence.

IT/OT network compatibility

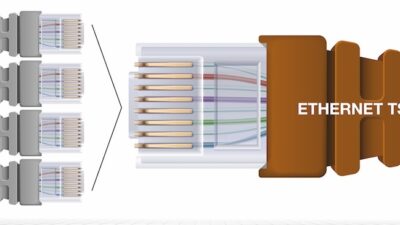

Standardized protocols are improving the movement of data around IT and operational technology (OT) networks. However, there is a class of communications that have forced islands of data, as required for deterministic performance. To solve this problem, protocols need to be compatible with TSN to deliver the benefits of converged networks while offering support for prioritized traffic.

Companies implementing factory automation projects should look for open network technologies that will address current needs, such as responding to the demands of Industry 4.0 with gigabit bandwidth, while providing TSN compatibility.

The importance of TSN technology is reflected by the way many standards bodies and industrial Ethernet organizations have worked to incorporate it into their portfolios. Their work provides a solid foundation for data and information integration among all the complex, disparate devices and applications that have previously been disconnected.

Connecting disparate technologies and making things work from a seamless interoperable standpoint is required to successfully build complete automation systems. Standardization allows design and deployment of complete systems using products from many vendors.

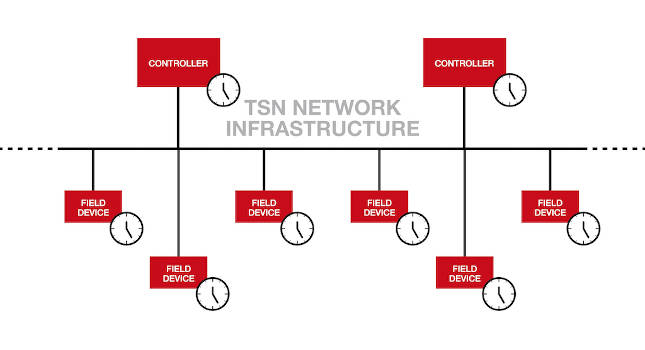

TSN also can provide many opportunities for convergence and interoperability. TSN can enable devices and applications, previously isolated to separate communications, to become part of a cohesive system. Different industrial Ethernet protocols can co-exist on the same network.

Networking standards in automation

Various open industrial Ethernet associations, and the OPC Foundation, have been working on adding TSN compatibility. The IEEE 802.1 group includes more than 30 standards, some of which may not apply to industrial use cases. Some agreement is required regarding which ones should be used for automation. To address this, the IEC (International Electrotechnical Commission) and IEEE (Institute of Electrical and Electronics Engineers) are working together to define a standard set of profiles for TSN in automation, based on an extensive set of use cases. This is known generically as IEC/IEEE 60802. However, many automation use cases are covered by the core IEEE 802.1AS and Qbv standards, which address time synchronization and prioritization, as we have already seen.

Vendors have introduced products that incorporate these standards. Moreover, the IEC and IEEE have a track record of backwards compatibility. Future standards will likely “grandfather” in any previous standards. The IEC/IEEE 60802 project also is planning to address the issue of TSN conformance testing. At least one open network organization is already offering this, and it is likely these activities will be combined with future, wider-reaching programs that include other organizations.

Time-sensitive networking (TSN) benefits

So, what does a company convinced of TSN benefits and wanting to adopt it do? The answer is to look for a technology that supports TSN while providing necessary application functionality, such as safety and motion control. It’s been almost three years since CLPA introduced CC-Link IE TSN, which involved using the established open industrial Ethernet CC-Link IE and adding TSN compatibility.

The result was the world’s first open industrial Ethernet technology to combine gigabit bandwidth with TSN. End users, machine builders and vendors can adopt a proven technology in products and projects.

For device vendors, developing CC-Link IE TSN compatible products help deliver the promise of Industry 4.0 in three ways:

- Performance: The only open industrial Ethernet currently available to combine gigabit bandwidth with TSN to provide the highest productivity via maximum bandwidth availability.

- Connectivity: Being an open technology maximizes the freedom of choice for end users and machine builders, while providing implementation flexibility for vendors. TSN offers the ability to combine CC-Link IE TSN traffic with other protocols.

- Intelligence: Reduce engineering time and maximize uptime with a range of features intended to simplify system design and maintenance.

A new era of interoperability

What does this all mean to the end user, machine builder, or vendor who is still wondering what to do with TSN? Vendors and standards organizations are adopting and pushing the TSN technology into their own standards and portfolios.

End users want choice and expect that networks and devices should coexist and work together to add business value. This allows data from previously disconnected devices to be converted into useful information to provide a complete cohesive implementation for industrial automation for today and tomorrow by leveraging TSN. The risk is not in adopting TSN now, but rather waiting several more years to implement and falling behind.

TSN offers several opportunities for manufacturers, such as determinism, and complete industrial and commercial network convergence. Network convergence is a key component addressing the challenge of greater transparency identified by Industry 4.0, allowing processes and manufacturing to be highly efficient, streamlined operations.

The evolution to TSN-enabled systems

For current industrial automation projects, organizations need to investigate which networking technologies will help improve operations. Gigabit Ethernet will help with this. Networks should also be open. Keeping an eye on future needs means identifying current technologies that will support TSN and provide an upgrade path to future TSN-enabled systems.

The technology landscape surrounding TSN is continuing to evolve, with the activities from the IEEE and IEC resulting in new advances. It’s a good bet TSN-enabled devices and networks installed now will work with the systems of tomorrow. Ethernet has been around for about 40 years and has evolved over that time, which is why it’s still in use today.

Technologies such as TSN will keep evolving to help companies meet current needs and help shape the next industrial revolution.

Machine builders and end users depend on TSN technology to connect legacy systems with the systems of today and, at the same time, address the complex needs of tomorrow. TSN can benefit development roadmaps, simplify machine designs and improve manufacturing operations.

Thomas Burke, global strategic advisor, CC-Link Partner Organization (CLPA), North America; John Browett, General Manager, CC-Link Partner Association (CLPA) Europe. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, [email protected].

MORE ANSWERS

Keywords: time-sensitive networking, TSN, Industrial Internet of Things

ONLINE

See additional Ethernet stories at Ethernet

CONSIDER THIS

What benefits can TSN provide for your facility?