A successful control system integration plan should cover all aspects from pre-sales planning, implementation and management excellence and communications. Project included PLC and input/output connections for system customization, redundancy, and precise control.

Learning Objectives

- General Control Systems’ (GCS) project at NanoFab Xtension (NFX) required cross-departmental collaboration at all stages of the PLC-based control system and I/O clean room system integration project.

- A particular challenge for the project was few individuals were permitted on-site at any time, which made logistics and planning difficult.

In 2011, General Control Systems (GCS) began work on the NanoFab Xtension (NFX) project at SUNY Polytechnic Institute’s College of Nanoscale Science & Engineering in Albany, NY. The successful completion of this project required cross-departmental collaboration at all stages through pre-sales planning, implementation and management excellence.

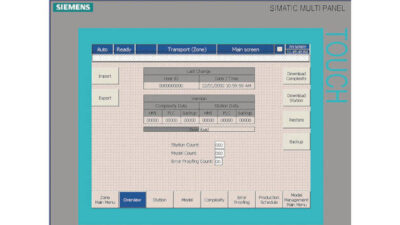

The pre-sales positioning for this project is a great example of how thinking outside of the box can add value for the customer. The project owner released strict specifications to solicit request for proposals (RFPs) to automate the building. The control system integrator used a programmable logic controller (PLC) to provide system customization, redundancy, and precise control for the sophisticated clean room application, which has more input/output (I/O) than a standard system.

This project had also called for the creation of a quality control plan, which had never been required before this project. A full-time quality control manager was dedicated to creating and overseeing the execution of the new program. It consisted of set standards for full documentation throughout all project phases. In addition to guiding internal operations, the plan guided communication with sub-contractors to adhere to the schedule and coordinate onsite services.

Project management challenges: Pre-calibration, quality management, certifications

One challenge for this project was few individuals were permitted to be onsite at one time. This made planning for deliveries, pre-calibration and pre-testing critical throughout the project. The new quality management system eventually led to Control System Integrators Association (CSIA) and ISO-9001:2015 certifications that guide GCS’ current quality management system.

Project management contributed to the excellent implementation of the project. This project was four times the size of any previous project the company had completed and the project manager was up for the challenge. Acting as the primary point of contact, the project manager (PM) coordinated with sub-contractors, adhering to project schedules, and satisfying quality and safety requirements to ensure that all aspects of the project ran smoothly. Direct interaction with the project owner and their engineering management ensured that project objectives and milestones were met.

The successful completion of the NFX project at this scale laid the foundation for exploring opportunities of similar size or larger in all industries. It also outlined a system that would ensure quality and consistency for future projects. The pre-bid approach of providing a creative solution paired with the development of a quality management system showcases the collaboration across departments to deliver an exceptional product for the end user.

Caroline Zimmer is inside sales and estimator and Mark Podbielski is a business development manager at General Control Systems at the time of this project. Edited by Chris Vavra, web content manager, CFE Media and Technology, [email protected].

MORE ANSWERS

Keywords: quality management system, project management

ONLINE

See additional system integration stories at https://www.controleng.com/system-integration/

CONSIDER THIS

What are your priorities when developing a PLC integration project?