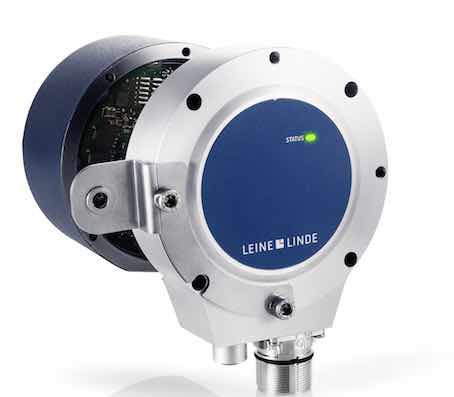

Leine & Linde's Advanced Diagnostics Upgrade (ADS) Unit for the model 800 rotary encoder can be mounted on encoders in the field and is designed to improve the encoder's operation and maintenance capabilities.

Leine & Linde has added an Advanced Diagnostics Upgrade (ADS) Unit to the model 800 rotary encoder. The encoder is designed for steel mills, paper mills, mining, and wind turbines. The ADS Online Upgrade Unit can be mounted on encoders in the field and is designed to improve the encoder’s operation and maintenance capabilities. ADS Online provides specific detail on the health of the encoder, enabling proactive maintenance to be performed should it be deemed necessary. ADS Online monitors a number of parameters that are fundamental for the encoder function like output voltage level, output states, the correct number of pulses, and that the optics performs within defined levels for supply current and brightness. In addition, vibration levels, hours of operation and internal temperature are also measured and logged. The operator can set alarm levels on any of these parameters, as well as set logging intervals for trend evaluation. By monitoring trends in performance, it is possible to predict end-of-life conditions and plan maintenance activities before a failure occurs.

Leine & Linde

– Edited by CFE Media. See more Control Engineering diagnostics and asset management products.