Industrial Ethernet is designed to withstand harsh environments found in industrial facilities and can be useful for companies looking to take advantage of Industrie 4.0 and the potential it can offer for the upcoming manufacturing revolution.

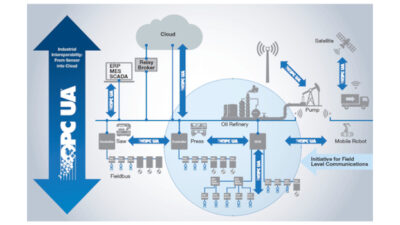

Manufacturing is undergoing a revolution, as advanced communication technologies, Big Data and innovations in automation converge to create more agile, productive and efficient operations. At the heart of the vision for Industrie 4.0 lies the communications network, which connects the entire enterprise: the plant floor, the back office, and remote locations, to create a single, seamless platform for information sharing.

Building these networks to the demanding standards for reliability, security and optimized uptime in production operations requires the deployment of more robust physical layer products and solutions. Industrial Ethernet can serve as a useful solution to this challenge.

Industrial Ethernet is designed to withstand harsh environments found in industrial facilities. Reliability and performance are essential, and network engineers who understand the risks and priorities of industrial networking are better positioned to make the right choices for their organizations.

What matters most in industrial environments

Discrete manufacturing is what most think of when they hear the term "industrial," but it actually includes a wide range of operations such as:

- Food and beverage production

- Chemical processing

- Pulp and paper production

- Power generation and distribution networks

- Transportation hubs and networks

- Critical infrastructure, such as bridges, dams and tunnels

- Military bases

- "Smart" traffic intersections

- Water treatment facilities

- Physical security systems.

While each industry is unique, the industrial nature of these environments share common factors, including priorities for each communications network. There are three mission-critical requirements for today’s industrial Ethernets:

- Safety: Protecting both people and processes is critical. To achieve the fail-safe reliability and redundancy for data transmissions that make safety possible, network components must exceed the requirements for hazardous environments.

- Uptime: Unplanned downtime is costly in both direct and indirect ways. One survey of automotive executives estimated the cost of unplanned downtime at $22,000 per minute. Reaching the 99.9999 percent uptime that ensures the smooth and reliable operation of facilities starts with preventing signal transmission problems.

- Control: The uninterrupted flow of signals between devices, machinery and the control system is necessary to the functioning of the highly automated environments in the factories of the future, with little or no margin for error.

In addition to having these priorities in common, all industrial environments share the characteristic of hazardous, extreme, and relentless conditions. Temperature, noise, vibration, corrosive chemicals, electromagnetic interfaces and power fluctuations are just some of the environmental norms that industrial communications and control networks not only have to withstand, but also be able to deliver consistent and reliable performance in spite of the conditions.

Enterprise vs. industrial Ethernet: Differences that count

Considering the environment in which industrial communications networks must operate—and the effect those conditions have on performance and lifespan—is the first step in understanding why even the best enterprise-class Ethernet solutions are not up to the task. For example, the extreme conditions and the impact of those conditions on Ethernet cables might include:

- Temperature extremes: Extreme cold can make cables stiff and brittle; extreme heat can wear down and weaken the plastic used to make the cables.

- Chemical exposure: Corrosives such as oil, solvents, and cleaning solutions can cause cable jackets to swell and lose strength.

- UV radiation: Exposure to sunlight can cause cable jackets to decompose more quickly, compromising strength and performance.

- Physical hazards: Machine movement and vibration can stretch cables with excessive force, degrading performance and increasing susceptibility to electromagnetic and radio frequency interference. Cables might also be crushed, cut or scraped by forklifts, carts or other moving vehicles on the production floor.

Making the grade: Testing works

To ensure products used in the physical layer of the network are able to perform in the harsh conditions of industrial operations, network engineers should be certain to examine the results of product testing. Environmental aggressors to consider include:

- Abrasion

- Cold bend and impact

- Crushing

- Cut-through

- Extreme heat

- Oil resistance

- UV exposure

- Water immersion.

The following certifications reflect the stringent regulations and ratings for networking products deployed in industrial environments:

- UL Tray Cable (TC): The basic rating for installation in 600V power trays

- UL CMR-CMX Outdoor: The basic and most common safety standard for communication cable

- C(UL) CMG FT-4: The basic and most common safety standard for Canada

- UL Verification Cat 5e/6/6a: Third party testing of electrical performance

- UL power limited tray cable (PLTC): The basic rating for installation in 300V power trays.

Built to maximize business value

When the communications network facilitates the flow of information among all stakeholders in the value chain—the production facility, the back office and even customers—business is optimized.

A complete, end-to-end Ethernet solution, built to withstand the rigors of an industrial environment, enables real-time visibility and flexibility, lowers maintenance and labor costs and allows for greater physical and virtual network security. The operational benefits at both the industrial facility and enterprise levels include:

- Faster and less costly upgrades, expansions and change-outs

- Access to real-time data to improve overall operations

- Faster installation and remote troubleshooting

- Real-time inventory visibility and increased production capacity

- Integration with enterprise resource planning (ERP) for scheduling, planning, quality tracking and delivery information.

With the right planning and wise investment in industrial-strength Ethernet infrastructure, organizations take a critical step toward building the high-performing communications network necessary for success in Industrie 4.0.

Brian Shuman is a senior product development engineering project manager at the Belden Engineer Center. Edited by Chris Vavra, production editor, Control Engineering, [email protected].

Belden is a CSIA member.