SEW-Eurodrive, provider of integrated power transmission and motion controls, has introduced Movifit Field Integrated Technology, which it calls the next generation in intelligent decentralized control. Movifit reportedly combines the advantages of decentralized control with the latest in drive application and communication technologies for automotive, food and beverage, logistics, and other so...

SEW-Eurodrive, provider of integrated power transmission and motion controls, has introduced Movifit Field Integrated Technology, which it calls the next generation in intelligent decentralized control. Movifit reportedly combines the advantages of decentralized control with the latest in drive application and communication technologies for automotive, food and beverage, logistics, and other sophisticated material handling applications.

The modular, in standard IP65- and hygienic IP69K-rated construction, provides a flexible and highly scalable platform for plant-wide decentralized control in a wide range of wet and dry environments. Preconfigured control routines for horizontal and vertical conveyor applications provide ready-to-use functions that simplify programming and start-up. Using standard conveyor modules, drive parameters can be set simply without configuration tools using DIP switches or programmed over a fieldbus network.

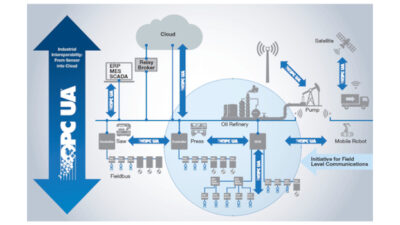

Real-time diagnostics for greater equipment availability is enabled through EtherNet/IP, Profinet, Profisafe, DeviceNet, and Profibus, simplifying integration with existing plant systems.

“In our field trials,” says Dave Ballard, SEW’s U.S. marketing director, “the unique capabilities of Movifit enabled customers to reduce the cost of design, installation and startup, compared to a centralized control system, by up to 30%.”

A library of preconfigured, reusable application routines reduces engineering and installation costs. Programming is simplified using standard IEC 61131 languages. The system accommodates many control topologies, including a master with up to seven slave units on one bus address, which reduces component costs. For more read this online at www.controleng.com/archive , September 2006. www.seweurodrive.com