Selecting a Profinet interface may enhance industrial network communication for devices.

Integrating an industrial communication interface into an automation device begins with gathering information to determine the industrial network’s functionality along with familiarization about the task at hand. Development tends to be faster for new devices if the wheel isn’t reinvented each time.

Depending on the functionality required (conformance class), it is essential to select the suitable type of implementation for each individual case. The available development capacity, company expertise, expected costs to produce the interface, and the time to market also play a large role.

A variety of starter kits and evaluation boards are available for most implementations. These sets enable a quick introduction to development activities and often contain a complete development environment, as well. Sample programs and circuits and block diagrams can be especially helpful. The development packages also include the certifiable Profinet stack of the corresponding provider and detailed documentation.

The plan of action and expenditure required for hardware and software design depend heavily on the selected implementation method. Here, a device manufacturer can carry out the development work independently or work collaboratively with a development or technology partner. Independent development requires well-grounded Profinet expertise and one’s own hardware and software development resources.

To unburden an automation device manufacturer’s development resources, PI member companies can provide complete development packages, ready-to-install Profinet communication modules, and a host of development services. These give the device manufacturer the support needed from the design phase to hardware and software development to certification.

Real-time requirements

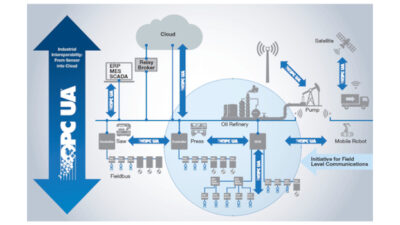

IEEE 802.3- Standard for Ethernet is designed to ensure problem-free communication between Profinet automation devices and among Profinet automation devices and other standard Ethernet devices. For applications with stringent real-time requirements, Profinet offers mechanisms that enable standard and real-time communication to coexist in parallel. Communication with Profinet can be scaled using three performance levels that build on each other:

- The transmission of engineering data and non-time-critical data occurs over transmission control protocol/internet protocol (TCP/IP). This standard communication is possible between all automation devices.

- The real-time (RT) channel is available for the transmission of process data.

- For isochronous applications like motion control, isochronous real-time (IRT) communication is used. This enables a clock rate of < 1 ms and a jitter of < 1 μs.

The IRT capability is based on hardware support in the device, which means special application-specific integrated circuit (ASICs), microcontrollers, and field programmable gate arrays (FPGAs) must be used for this purpose. Commercial-switch ASICs without IRT hardware support are suitable for implementing an automation device with RT capabilities only. Devices with RT communication can be developed based on standard Ethernet components and a Profinet software stack.

Profinet conformance classes

To meet the different requirements of automation systems, three conformance classes that build upon one another are defined for Profinet. Each class has a functional scope determined for the typical area of application. The device manufacturer must consider the required conformance class before selecting an implementation option for the Profinet device interface because the type of interface implementation affects the conformance class that can be achieved.

The key functions of the three conformance classes and their advantages are described below:

- CC-A: Using the infrastructure of an existing Ethernet network, including integration of basic Profinet functions. All information technology (IT) services can be used without restriction. Typical application examples are found in building automation and process automation.

- CC-B: The functional scope of CC-B comprises the functions of CC-A, plus it supports user-friendly device replacement without needing an engineering tool. Simple network management protocol (SNMP) supports extended device diagnostics of network functions such as port status messages. To increase data reliability, a performance-adapted media redundancy protocol is available as an option. All IT services can be used without restriction. Typical applications can be found in automation systems with higher-level machine control with a deterministic, but not isochronous, data cycle. The vast majority of Profinet devices fall into this category.

- CC-C: The functional scope of CC-C comprises all the functions of CC-B. It also supports high precision and deterministic data transmission, including isochronous applications. The integrated optional media redundancy enables smooth switchover of the I/O data traffic if a fault occurs. All IT services can be used without restriction. Typical applications are in the field of motion control.

Once a device manufacturer has decided what Profinet features they need to implement on a product, the next question is how to implement those features. There are three options:

- Drop an ASIC onto the printed circuit board (PCB) to handle Profinet communications. If the real estate is available on the PCB for a chip, this might be feasible. The downside is physical chips do involve a per-unit cost. It’s tough to drive the marginal cost down with volume. The upside is ASICs tend to be more fully featured than other implementation options. So, if one needs to implement Profinet with all of its features, there is available enclosure space in the enclosure, and the per-unit cost isn’t an issue, this is a great way to go.

- Plug a module into a slot on the device PCB. Unlike ASICs, a module can deliver the network requirements with physical cable connectors, magnetics, PHYs (physical layer circuits for the physical layer of the OSI model), an integrated Ethernet switch, and a chip to handle the Profinet stack. There is a range of backplane connections available–everything from dual-port memory to SPI to the compact flash (CF) card interface. Most vendors offer interchangeable protocol implementations that use the same backplane connector, so it can offer Profibus, Profinet, or other protocols with a simple module change. Per-unit costs are higher than with an ASIC, due to the extra hardware involved.

- Buy a software stack and implement it on the application processor. Software stacks are one of the most common Profinet implementations–they’re the most cost-effective way to implement the protocol in volume. However, they’re also the most complex way to implement Profinet. Stacks touch a lot of peripheral software pieces such as the operating system, the IP stack, the nonvolatile RAM, and so on. With each external component that interfaces with the stack, there’s an opportunity to break the protocol. Choosing to implement a Profinet stack means the company will almost certainly have to invest in training and outside consultation.

| Software stack | ASIC/FPGA | Module | |

| Integration effort | +++ | ++ | + |

| Per unit cost | + | ++ | +++ |

| Lifecycle cost | ++ |

+ Lower | ++ Medium | +++ Higher

Time-sensitive networking (TSN) and Profinet

Time-sensitive networking (TSN) is a promising technology and offers a lot of potential for Profinet. TSN aims to combine the wide range of IT networks with the robustness and determinism of automation networks. In short: hard real-time via standard IT networks. This doesn’t signal a revolution for Profinet. Rather, it represents a visionary architecture upon which Profinet is building.

TSN offers Profinet a new layer 2 in the ISO/OSI model. It corresponds to today’s RT and IRT technologies. This makes it clear TSN will not replace RT or IRT in the coming years. It’s an additional option with a number of potential benefits. Today’s manufacturers that are providing solutions with RT and IRT will be able to continue providing them in the future. Users employing RT or IRT to operate their systems can be sure that they are using a sustainable technology.

TSN offers the possibility to also achieve this with standard chip-sets because TSN is based on open standards, which is supported by many semiconductor vendors. Everything else about Profinet remains unchanged–especially services such as diagnosis, configuration, alarms, etc. This will make it easy for users and device manufacturers to use TSN in the future. They can build on existing knowledge and continue using the applications they have developed.

Michael Bowne, executive director, PI North America. Edited by Emily Guenther, associate content manager, Control Engineering, CFE Media, [email protected].

MORE ANSWERS

KEYWORDS: Profinet, time-sensitive networking (TSN)

Conformance classes for automation systems

How to implement Profinet features

The benefits of time-sensitive networking (TSN) and Profinet.

Consider this:

How can a Profinet interface enhance communications for your operation?

Online extra

PI North America provides more information for developers at us.profinet.com/development.