Advanced applications for machine vision in automotive, robotics, quality, and safety use hybrid technologies, vision for robotic or machine guidance and in-line part inspection, and 3D imaging. Technology and imaging standard advances help.

Advanced applications for machine vision in automotive, robotics, quality, and safety use hybrid technologies, vision for robotic or machine guidance and in-line part inspection, and 3D imaging. Technology and imaging standard advances help. The articles below appeared in the Control Engineering May 2013 North American print and digital edition and are linked below, online, with additional information and images.

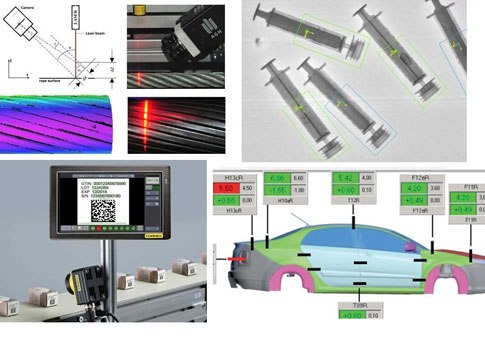

Quality control measurements for smooth surfaces

Hybrid laser-camera technology is ideal for surface measurement in many industries. The camera detects a laser projected onto an object at a specific angle.

Next generation: Robots that see

Visual servo control: Vision used for robotic or machine guidance also can be used for in-line part inspection to enhance product quality with traditional feedback systems. See online video.

3D vision system performs rope wear analysis

Three-dimensional (3D) imaging can be used to verify rope and cable quality to measure pitch length and diameter, and identify rope surface damage and type of wear, with accuracy surpassing current methods, to enhance safety. See photos.

Advances in machine vision products, standards

Recent new products and standards advances include FDA traceability, higher speed, and connectivity and integration standards.

– Articles edited by Mark T. Hoske, content manager, CFE Media, Control Engineering, [email protected].

Control Engineering machine vision article library.