In an August 15, 2023 webcast, "SCADA series: New SCADA features and functions," Avanceon’s Nicholas Imfeld joined Control Engineering to discuss SCADA innovation topics including situational awareness, window hierarchy, tiered navigation, enhanced alarms, historical data and trending, standards and conventions, distributed architecture, virtualization, and variety of access methods. Read part 2 of the edited transcript below.

SCADA insights

-

In an August 15, 2023 webcast, “SCADA series: New SCADA features and functions,” Avanceon’s Matt Ruth and Nicholas Imfeld joined Control Engineering to discuss the key innovations in SCADA software packages that can improve efficiency and outcomes for end-users.

-

In Part 2, Nicholas Imfeld, operations manager at Avanceon, discusses SCADA innovation topics including situational awareness, window hierarchy, tiered navigation, enhanced alarms, historical data and trending, standards and conventions, distributed architecture, virtualization, and variety of access methods.

-

Read Part 1 for more information on the common drivers of SCADA system upgrades, Part 3 for a SCADA upgrade case study, and Part 4 for information covered during the webcast’s live question and answer session.

Software for supervisory control and data acquisition (SCADA) has advanced to provide greater capabilities with less programming. What are key traits of SCADA software packages that make an upgrade worth the investment? Advantages include integration of certain standards; built-in communications and connections to other devices, software and systems; extensive libraries of code; integration with cloud capabilities; easier porting to mobile clients; and analytics. In an August 15, 2023 webcast, “SCADA series: New SCADA features and functions,” subject matter experts joined Control Engineering to discuss these topics and more. The featured webcast instructors were:

-

Matt Ruth, President, Avanceon

-

Nicholas Imfeld, Operations Manager, Avanceon

Below, the transcript of their presentations has been provided with minor edits and adaptations.

Situational awareness

Nicholas Imfeld: Situational awareness, often referred to as high-performance HMI, is a critical concept. The essence of situational awareness lies in transforming data into information for effective decision-making. This involves transitioning SCADA HMI windows from traditional process graphics to a more contextual dashboard style. Another significant change in situational awareness SCADAs is the minimal use of color, directing focus only to what is crucial. For instance, in a brief view of a window, you might notice a yellow indication or a red warning for an alarm, signaling areas needing attention, with red likely being the priority. I will also introduce concepts from various situational awareness toolkits. These concepts are not platform-specific but are general approaches applicable to any SCADA platform.

We developed a window exemplifying these situational awareness principles. For example, we have a pump represented; its inactive state indicated by a white fill color and the active state by a gray color. Familiarity with these conventions allows users to quickly understand the device’s status. The focus here is not merely on whether the device is running, but whether it is operating as commanded.

Contrastingly, we have a pump with a medium severity alarm, denoted by its border, and another device with a critical alarm, indicated by red. Additionally, there’s an analog transmitter showing the process variable with vertical fill, and small flags mark the configured set points. The gray bar indicates that the value is within the desired range.

Windows hierarchy

Moving on to window hierarchy, this concept, independent of any particular platform, is increasingly used in SCADAs. Typically, SCADA systems are designed with four levels of window hierarchy, each serving a distinct purpose. Level 1 usually provides an overview of the plant or area, offering a quick glance at operational status. Level 2 is for operational control, where most automatic controls, phases, and recipes are managed. Operators commonly use this level. Level 3 delves into equipment details for in-depth analysis or troubleshooting. Level 4 involves control and status, housing pop-ups for device control, phase control and control modules. Establishing what appears on each level requires careful planning, understanding of the process, and consideration of user needs. This approach contrasts with traditional methods and often requires several iterations to perfect the details for each level, blending science and art.

A recent project’s Level 1 window, for instance, featured a layout where key data points were more segregated than usual but provided all necessary information. Progressing through the navigation to a Level 2 operation screen, we see a wireframe flow diagram. It doesn’t depict equipment location but rather its flow and organization, displaying key operational data. Drilling down further, a Level 3 window shows detailed information for a screening area, offering deeper insights into the operations.

Level 4 has seen an increase in available information and configuration options at the HMI SCADA layer. Traditionally, this information was confined to controllers or physical devices. These pop-ups are designed with a consistent look, feel, icons, and labeling, regardless of their specific function, and include various controls and custom system elements.

For example, we have a simple VFD pop-up designed for low-security users and a more complex one for higher security access. The standard configuration is displayed on one side, with detailed options on the other, accessible via buttons. This approach is about providing more extensive information and configuration through these pop-ups.

We also have a phase control pop-up, maintaining a consistent style and button layout. It displays a list of interlock conditions, highlighting the specific issue preventing operation.

Regarding alarms and alerts, it is becoming standard practice for these to appear on windows and be traceable back to the specific device pop-ups. This feature enables users to directly identify and address the root cause of any observed issue.

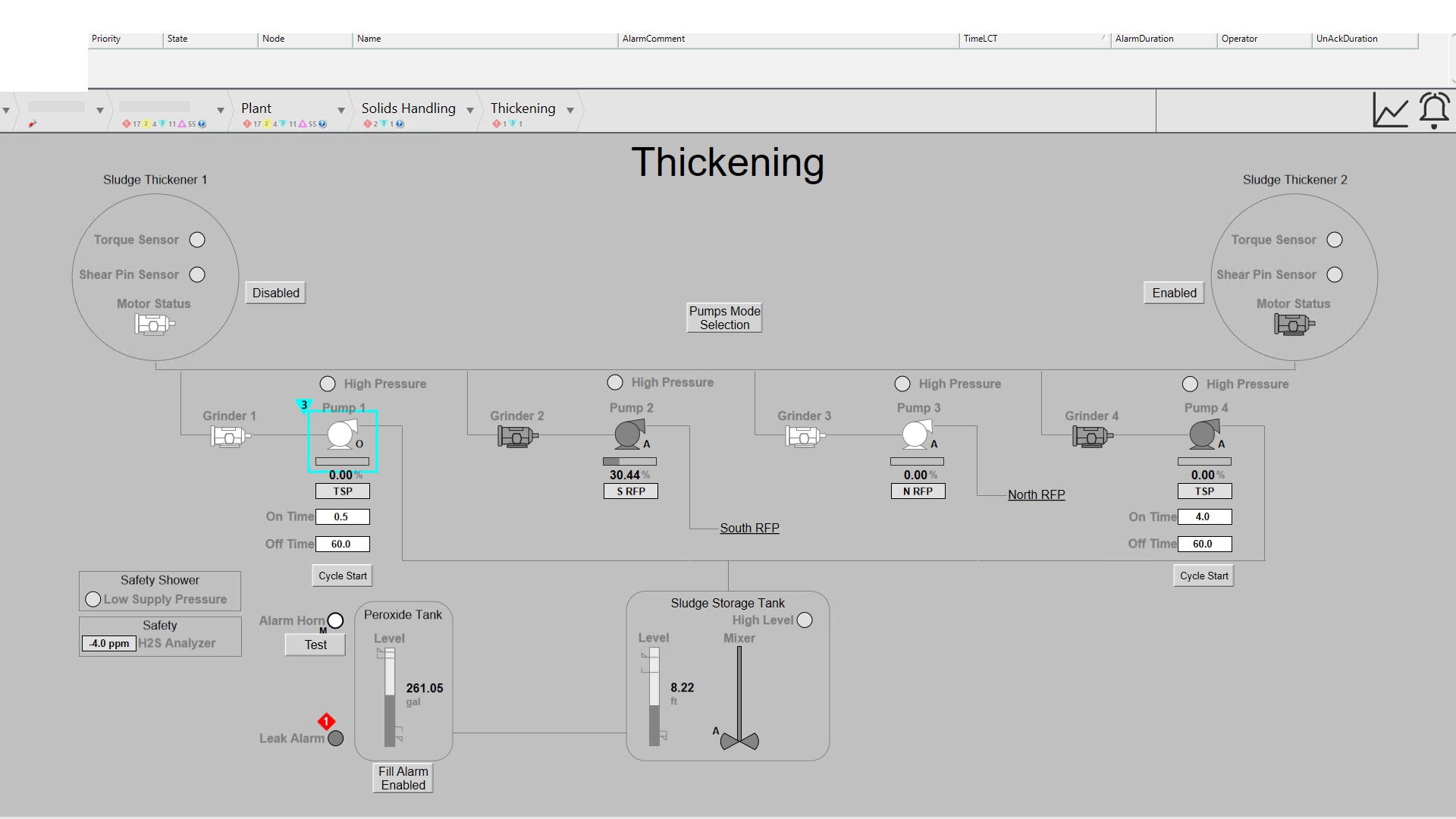

Tiered navigation, closely related to window hierarchy, involves starting at Level 1 windows and progressing through the tiers. For example, in the solids handling area, selecting ‘thickening’ at Level 2 brings up a list of Level 3 windows for more specific navigation. Another approach uses multiple navigation bars, where selecting a window at one level automatically brings up related windows at the next level,

Enhanced alarming

Enhanced alarming addresses the challenge of excessive and often irrelevant alarms in legacy SCADA systems. By categorizing alarms by severity and representing them with specific colors, numbers and shapes, users can quickly ascertain which issues need immediate attention. Enhanced alarming also introduces tools like shelving alarms, which temporarily hide alarms without disabling them, useful in maintenance scenarios. Other management states include suppressing, silencing and disabling alarms, each aimed at reducing noise and focusing on critical alerts. This functionality is integrated into the tiered navigation and window hierarchy, with alarms and warnings displayed in the navigation bars, guiding users to the specific window and device with the issue.

Historical data and trending

Historical data and trending represent another key aspect of modern SCADA systems. With the increasing availability of data points and more affordable data storage, much of this data is logged for historical analysis. This historical record is vital for understanding system operations and is increasingly being integrated into HMI windows for real-time trend analysis. Moreover, full trend tools provide access to all historical data, laying the groundwork for advanced applications like reporting, analytics, and AI-driven predictive maintenance.

Standards and conventions

Finally, standardization is essential in SCADA systems. It involves using a toolkit with pre-developed application structures, screen designs, objects, graphics, styles and approaches to alarming events and trending. The aim is to create a consistent and efficient deployment process that can be reused across different systems. Standards are not just for SCADA but apply to all system aspects, including PLCs, electrical design and documentation. A standardized approach to device naming conventions, based on a hierarchical system view, ensures consistency and ease of use.

Distributed architecture and virtualization

In terms of architecture, modern SCADAs are moving away from traditional industrial computers on the plant floor to thin clients and virtual servers. Thin clients, functioning as remote desktop clients, are cost-effective and easy to replace. Virtualization offers advantages in backup, disaster recovery, redundancy, and high availability. It allows for the right-sizing of server specifications based on specific needs, such as network communication or data storage requirements.

Variety of access

Lastly, the variety of access methods available today, thanks to technologies like HTML5, high-definition displays, mobile devices, scalable graphics, VPNs, and thin clients, has significantly expanded. SCADA windows, once developed for single use, can now be accessed from virtually anywhere, including multi-monitor stations, tablets, phones, control rooms, and through web browsers for non-plant floor use. This flexibility has revolutionized how SCADA systems are deployed and accessed.