With the industry on the cusp of adopting the Industrial Internet of Things (IIoT) or Industry 4.0, security has to be a part of it.

Make no mistake about it, cybersecurity is here to stay and Honeywell is banking on the fact that users will either build upon their existing program, or they will pick a partner and step up and start to dance.

With the industry on the cusp of adopting the Industrial Internet of Things (IIoT) or Industrie 4.0, it is clear, security has to be a part of it.

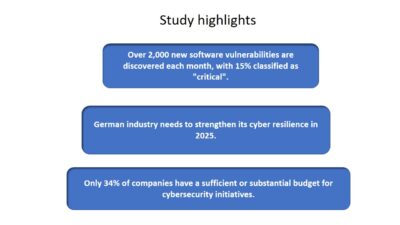

“The move from industry 3.0 to Industrie 4.0 is contingent on cybersecurity,” said Vimal Kapur, president and chief executive of Honeywell Process Solutions (HPS) during his keynote address Monday the 2017 Honeywell User Group Americas in San Antonio, TX. “It is new and we have to learn it very quickly. The numbers are pretty small in companies doing audits and remote security management.”

But Kapur is sure that will change.

“Cybersecurity risk is imminent,” he said. “We need to strengthen our defenses.”

Among the investments Honeywell is making in cybersecurity include the acquisition of NextNine, a new cybersecurity center in Singapore, releasing the SMX USB security solution, releasing an update to Risk Manager, in addition to beefing up its services offerings.

Cybersecurity was not the only aspect Kapur talked about during his keynote, as Honeywell is pushing its Connected Plant offering out to the industry.

“Challenges facing manufacturers and plant operators today have not dramatically changed in the last 40 years. Safety, efficiency, reliability, productivity and security continue to drive innovation across industries,” Kapur said “What has changed is our ability to better address these challenges. Today, we are able to leverage the power of the internet to employ a broader range of data to transform operations.”

“Forty years is not a long time, but in our industry it is,” Kapur said. “Industry 3.0 started in 1975 with automation. It was very transformational. There have been no paradigm shifts until about 2000 with adoption of open systems. In 2012-13, Industrie 4.0 was announced in Germany with the use of Internet to drive a new level of excellence throughout the industry. It will take several years to master.”

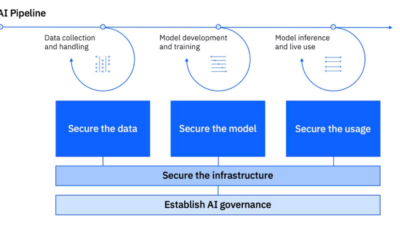

The unspoken word about jumping on board the Industrie 4.0 train is security has to come aboard because organizations will end up deluged with a multitude of attack vectors.

Part of the move to Industrie 4.0, Kapur said, is the addition of these disruptive technologies that will have an effect on businesses:

- Cloud

- Connected plant

- Virtualization

- Virtual reality

- Digitization.

Virtualization will reduce the total cost of ownership. Virtualized systems will deliver at least 30% reduction in total cost of ownership, he said. “Virtual machines are a pillar for any new architecture.”

A connected process added with connected assets, plus connected people all add up to the connected plant, he said.

What makes the IIoT or Industrie 4.0 work is connectivity and being able to ship data to the right people at the right time with a proper level of context.

“Data needs to be available to the experts via secure solutions,” Kapur said. Honeywell is expanding its capabilities by:

- Keeping data secure

- Creating a digital twin, which is building a process model in the cloud to build a twin for the plant. It acts as a model of the assets and a model of the process.

- Analytic capabilities

- Asset expertise, process expertise, equipment expertise

- Visualization and collaborative tools.

“We acknowledge there will be adoption barriers,” Kapur said. “The amount of opportunities technologies now provide is so great. We should not step back and think about why it can’t be done. We have to look at how it can be done.”

Gregory Hale is editor and founder at ISSSource. He has over 25 years in the publishing industry. This article originally appeared at ISSSource.com. ISSSource is a CFE Media content partner. Edited by Hannah Cox, content specialist, CFE Media, [email protected].