It's been more than five years since the World Wide Web Consortium (www.w3c.org) released XML (eXtensible Markup Language) version 1.0. Since then, countless articles have claimed that XML's simple, text-based format would change forever how data are exchanged among different authoring applications on and off the Web.

At a Glance

ISA/S95

B2MML

XML schemas

Data centric

Application integration

It’s been more than five years since the World Wide Web Consortium ( www.w3c.org ) released XML (eXtensible Markup Language) version 1.0. Since then, countless articles have claimed that XML’s simple, text-based format would change forever how data are exchanged among different authoring applications on and off the Web.Five years after its introduction, complex implementations are proving the benefit claims attributed to XML were accurate.

Keeping the promise

Many of those proclaiming that XML provided a data exchange technology breakthrough did so from a business-to-business perspective.

One exception came from a small group of dedicated individuals toiling to define a standard that identified the general functions and information necessary to integrate business and manufacturing systems. Initially known as the ISA/S95 standard “Enterprise-Control System Integration,” S95-1 and -2 have since received international standard status as IEC/ISO 62264-1 and -2. The committee is targeting for part three of the standard to obtain international status in 2004.

Though the standard does not define a formalized protocol for information exchange, several committee members recognized the importance XML could play in making the standard more easily implemented.

Under the stewardship of the World Batch Forum (WBF, www.wbf.org), a working group was formed and began developing the XML schema “Business to Manufacturing Markup Language” (B2MML).

Released as a royalty-free implementation of the ISA/S95 standard, WBF’s B2MML provides a set of XML schemas developed using the XML schema definition (XSD) language.

B2MML successes

Empresas Polar ( www.empresas-polar.com ), a food and beverage corporation based in Caracas, Venezuela, with the assistance of system integrator MPR de Venezuela, is among companies that have used the S95 standard and WBF’s B2MML schemas to develop an interface between a SAP R/3 ERP (enterprise resource planning) business system and plant floor MES (manufacturing execution system).

Some vendors offer proprietary “standard” implementations. Using these can create a support nightmare that’s best avoided.

“Our previous success with the ISA-S88 batch standard provided us significant confidence to apply the ISA-S95 standard. Its clear, flexible, logical structure eliminated time-consuming discussions on the logic and types of messages that need to flow between the plant floor and the business system, reducing, if not eliminating, communication stress on the IT-engineering team,” said Francisco Ferrero, project manager for Polar Beer, a unit of Empresas Polar.

“By using simple XSLT transformations [extensible stylesheet language transformation] at the SAP Business Connector side, we were able to simplify the SAP R/3 BAPI [business application programming interface] calls into a more manageable, standardized format. In short, with very little effort, we were able to make SAP ‘speak’ B2MML,” said Alejandro Imass, senior consultant at MPR.

Using a standards-based implementation creates an easily supported solution.

“The use of S95, XML, XSLT, and off-the-shelf software permitted us to deliver a complete interface with SAP PP-PI [production planning for process industries] and the plant-floor MES in about five weeks. We estimated this could have easily taken a year using traditional methods,” added Imass.

SAP’s R/3 BAPI includes some very specific datatypes that aren’t part of the B2MML implementation. However, B2MML does allow defining “Any” types at any level. This designed-in B2MML extendability makes it easy to accommodate special cases.

Another adopter of B2MML is Arla Foods ( www.arlafoods.com )—a co-operative established in the spring of 2000 through the merger of Danish MD Foods and Swedish Arla.

As many readers already know, mergers produce system integration challenges up, down, and all around the “new” enterprise.

Arla Foods is no exception. With five divisions producing three categories of dairy products at 70 production sites, Arla Foods faces major integration challenges.

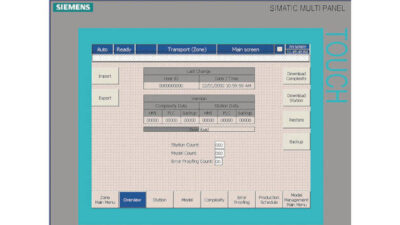

In terms of control and information system complexity, Arla Foods has multiple suppliers of ERP systems, MES, PLCs (programmable logic controllers), and HMIs (human-machine interfaces).

Arne Svendsen, Arla Foods production-IT coordinator said, “Company wide, we’ve launched a project called ‘EttArla’ [meaning OneArla]. The goal of EttArla is to harmonize the data produced by our global business and production processes. Today we have three ERP systems, with a preference for SAP’s R/3. We have talked to our MES suppliers about the need for them to include support for ISA/S95-2 data models. Unfortunately, most MES products were developed pre-S95 and suppliers have been slow to include B2MML techniques in their products. We view WBF’s B2MML as the ‘wallbreaker’ for integrating complex, proprietary applications.”

Using XML schemas to build standardized application adapter/connectors permits managed data integration.

In 2002, Arla Foods launched a pilot project designed to develop a standardized means of integrating production data across the enterprise.

Goals of the ongoing Arla Foods pilot project are to ensure:

Production schedules and performance data are shared in a timely manner;

An accurate accounting of inventory is maintained including custody transfer data (i.e., milk delivered by trucks);

Laboratory information system information is available for exchange; and

Plant maintenance information is available for exchange.

“Among the things the pilot project taught us is there are very few SAP consultants with experience in integrating to MES and less than a handful of MES-vendors with practical, hands-on XML experience,” said Svendsen.

Svendsen’s hindsight lessons include:

Do a better job of project management;

Have a full-time resource assigned to tie-up loose ends among project participants;

Ensure the MES vendor’s B2MML connectors are fully developed and proven; and

Educate and use your own staff to develop the SAP business connectors.

Despite a few pilot project surprises, Arla Foods is on schedule to apply its B2MML integration solution in a production facility in October 2003.”We remain enthusiastic about the benefits of adopting S95 and B2MML and fully expect subsequent projects will reuse 100% of our SAP development investment,” explained Svendsen.

XML links applications

The September ’03 issue of Control Engineering included a feature titled, “Maintaining a Single Source of Truth.” The article introduced The Engineering Framework (TEF) solution cooperatively developed by Aspen Technology, Dow Chemical, and Intergraph PPO. TEF is an example of technology being developed to avoid the erosion of engineering information.

A key underlying technology of TEF is XML. (See, “Sharing Engineering and Control System Information” diagram.)

TEF environment relies on a publish/subscribe model designed to support the front-end engineering and design workflow process. Each authoring application creates data-centric application-specific information. When the application developer is ready to share content, they publish, via the TEF adapter, to the TEF server. Depending on the published information’s status—inform, read line, approve, construct, etc.—subscribing users are notified and permitted to participate based on administrative and workflow rules.

When published information becomes approved and available for use by the next authoring application, it uses its TEF adapter to extract the appropriate data from the TEF database to populate its own database. Thus equipment tags, descriptors, engineering units, fluid properties, etc. created in the first authoring application are reused in subsequent authoring applications.

TEF is far more than a means to share data, it also accommodates change control management, workflow management, and audit trail.

For example, a workflow management rule could prevent populating the Intools instrument database until certain approvals are obtained for the piping design content developed using SmartPlant 3D.

Also shown on the “Sharing Engineering and Control System Information” diagram is an example of ABB’s Aspect Exchange Services (AES) connector. AES is yet another XML implementation designed to manage data sharing between authoring applications, in this example between Intools and ABB’s Aspect Objects.

Support issues

Many control engineers have experienced the support burden associated with point-to-point and centralized database integration efforts.

As individual companies issue new product releases, point-to-point and centralized solutions become fragile and frequently require considerable testing and maintenance to ensure data integrity.

XML implementations for B2MML, TEF, and AES can minimize impact of software upgrades. As long as the underlying data structure and/or platform remains unchanged, each authoring application supplier can make product changes without impacting the XML connectors and adapters, thus minimizing maintenance and support activities.

Robert Sammons, principal industry consultant at ABB explains, “Connectors require a minimum of maintenance, although they could require some updates if an application supplier changes its platform base. Connectors are made via standard OLE [Object Linking and Embedding] database calls. SQL [Standard Query Language] statements are governed by the connectors and managed by the database provider. Therefore, no maintenance is ever required at the connector level. Simple tweaks may be required at the flow object level, which governs how the XML data set is manipulated and parsed.”

Consistent with templates in WBF’s B2MML XML schema set, ABB’s AES and Intergraph PPO’s TEF integration environments make templates available that allow third parties to create bidirectional data flow adapter/connectors.

Occasionally a disruptive technology makes people stop and reconsider how they do things. XML is a disruptive technology. In just five years, XML has changed the way people think about how to share data across the enterprise. XML isn’t hype, it’s real, robust, and available.

Comments? Email: [email protected]

For more suppliers:

go to www.controleng.com/buyersguide ; www.controleng.com/freeinfo

ABB : www.abb.com

Intergraph PPO : www.Intergraph.com/ppo

MPR de Venezuela : www.grupompr.com

World Batch Forum : www.wbf.org

Online Extra Side Bars

Mneumonics defined COM : Component Object Model DCOM : Distributed Component Object Model OLE : Object Linking and Embedding OPC : OLE for Process Control SOAP : Simple Object Access Protocol XML-DA : eXtensible Markup Language-Data Access

OPC can have XML inside

The OPC Foundation’s (www.opcfoundation.org) OPC XML-DA standard is based on XML instead of Microsoft Windows’ COM/DCOM. OPC XML-DA provides a simplified, interoperable foundation for sharing and exchanging data throughout the enterprise.

OPC XML-DA specification differs from previous OPC data access specifications by describing data exchange in an environment that doesn’t assume or require there’s a continuous connection between client and server.

It’s the Web services environment, including XML and SOAP, that allows the OPC XML-DA specification to leverage the broader range of communication systems and interoperability provided by the XML standard.

OPC Foundation president, Thomas Burke, explains, “The current XML-DA interfaces closely parallel the existing OPC COM-DA interfaces. It’s this parallelism that enables developers to write a middleware XML-DA server that connects to underlying COM-DA servers. Once created, thousands of existing COM-DA servers will become Web service servers.”

OPC server developers have already begun to release .NET Web service applications based on the OPC XML-DA standard.

Also, anyone using or developing OPC should be aware that the OPC Foundation is considering using OPC XML-DA as a transport mechanism for the ISA/95 reference model. Since the ISA-95 specification is a conceptual modeling framework between business enterprise and factory operations, OPC provides a potential for an off-the-shelf implementation of the ISA/S95 standard.