Automation system integrators provided advice on getting started with automation, digitalization, collaborating on automation projects and more at Automate 2025.

System integrators provide automation insights

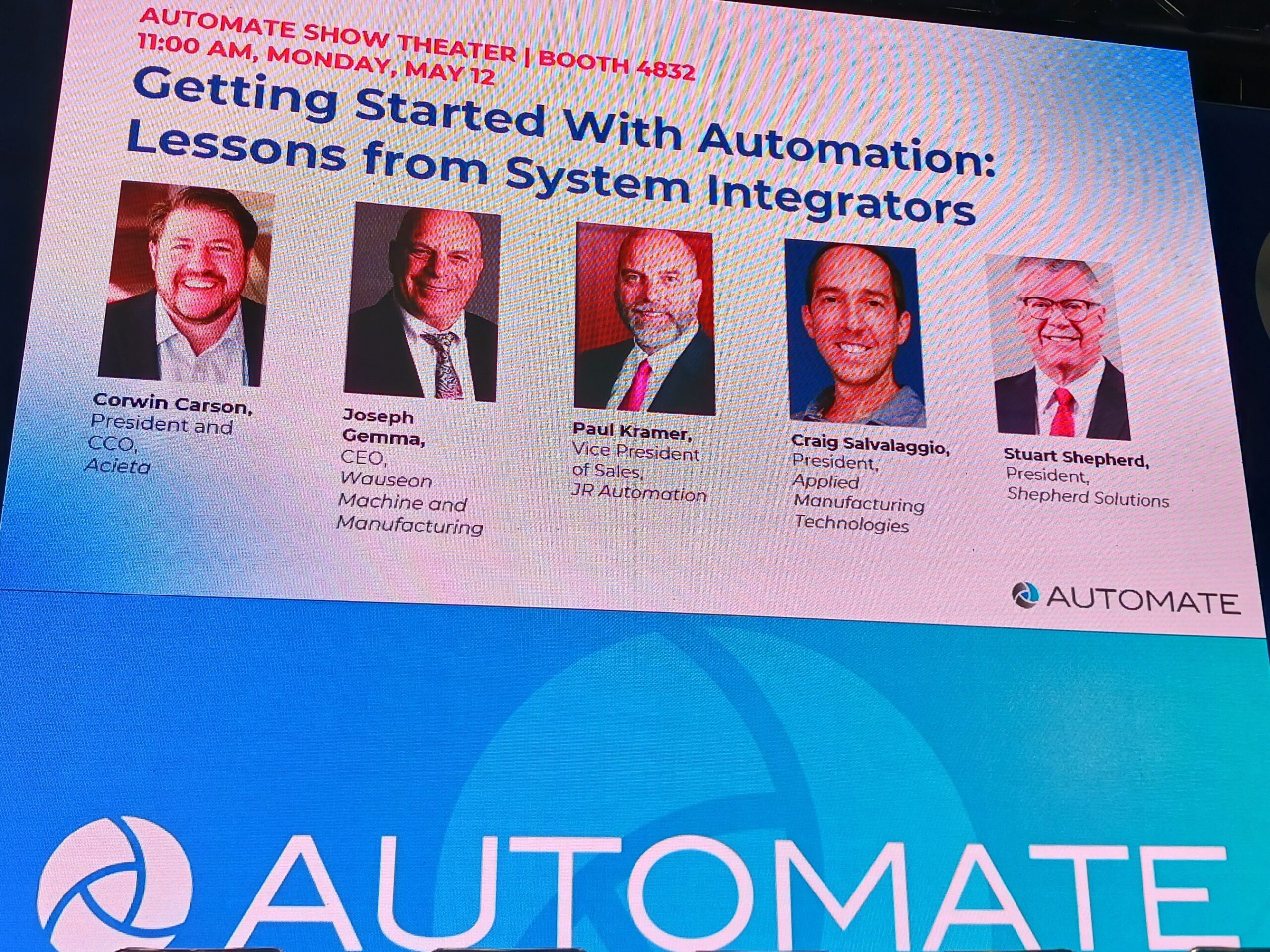

- A panel of control system integration experts from Acieta, Wauseon Machine, JR Automation, Applied Manufacturing Technologies and Shepherd Solutions provided advice about “Getting started with automation: Lessons from system integrators” at Automate 2025.

- Other automation system integration topics covered include system integration project collaboration, digitalization and digital twins.

- When and why companies should automate, workforce readiness for automation and other ways system integrators can help automation projects.

A panel of system integrators provided advice about automation implementation and working with system integration firms at Automate 2025, by the Association for Advancing Automation (A3). The May 12 session in the Automate Show Theater, “Getting started with automation: Lessons from system integrators,” was part of Detroit event, May 12-16, with more than 800 exhibitors and more than 140 conference sessions on robotics, machine vision, artificial intelligence and other industrial automation topics. Panelists were:

- Corwin Carson, president and chief commercial officer, Acieta

- Joseph Gemma, CEO Wauseon Machine and Manufacturing

- Paul Kramer, vice president of sales JR Automation

- Craig Salvalaggio, president Applied Manufacturing Technologies

- Stuart C. Shepherd, president Shepherd Solutions; he moderated the system integrator panel. (Shepherd won a 2025 Engelberger Robotics Award).

Paraphrased questions from Shepherd follow with edited replies from panelists.

How do you describe the customer journey with automation?

Carson: Our relationship with clients is about the customers, the end users, and their journeys with implementing automation. Workflows and automation can be complex, and things will go right and wrong. We want customers to enjoy the process. And we collaborate to understand where customer is on journey. What is their end goals? Expectation alignment leads to success. We like to spend time with them on the plant floor to understand their business. Developing a matrix of where they are at and where want to be can be very helpful.

How do you know if a customer or a process is ready to automate?

Gemma: If this is the first time a customer is using automation, we remind them not to try to boil the ocean. Start small, defined a process and look at tools, processes and data. Understand how the automation implementation aligns with company goals and objectives.

How can automation users use safety technologies and related standards without feeling trapped?

Kramer: Safety is on top of every customer’s chart. When enter the automation space, understand the potential of the equipment and the hazards. Understand safety protocols and review the designs. A system integrator can help navigate the path to balance cycle times and speeds with safety.

Shepard: A3 updated robotic safety standards recently.

Gemma: A system integrator can help with risk assessment, but if you modify it, do own homework. You are responsible for employee safety, with or without changes to automation changes.

Salvalaggio: Standards can be intimidating. If involved early, we can help to inherently design products and processes to improve safety and reduce risk. Operators and maintenance need to be safe from the start and be comfortable with ease of use to culturally adopt the automation. It smooths the process for system integrators to be involved from the quoting process at the start of project.

We’ve all seen slick YouTube videos of automation: What’s real?

Gemma: Walk the show (speaking of Automate 2025). Look and talk to others. Ask the same questions of multiple technology providers to understand differences. We want to help. OEM manufacturers should help, too.

Salvalaggio: Live examples of working technologies are helpful, and keep in mind that like videos, demonstrations can differ from live 24/7 production processes.

Kramer: Demonstrations and simulations can help customers unify expectations, understand what they are and provide proof of principles. At a show, many demonstrations have been prepared over months. Mixing in real-life variations can create challenges.

Carson: Technology can be advanced through simulations to lower risk once implemented.

Gemma: Note that animations differ from simulations that match the real world.

Kramer: When shown a simulation of automation, ask for data to show how the simulation matches reality.

How do you help justify automation to ensure the implementation makes money?

Salvalaggio: We work to help customers understand safety, throughput, productivity and total ROI, not just cost savings from repurposing and reskilling any workforce involved. Look at reducing risk in automation designs and look at how machines produce ROI.

Kramer: Automation helps processes continue. Customers have jobs where they cannot find operators to run regularly. It’s not just about hiring operators. Now it has to do with consistency of finding a skilled workforce.

Gemma: The real cost of ownership includes training, recruiting, training, moving and restarting the process with automation. It’s not just headcount.

Carson: Labor per shift on a chart has become irrelevant. Helping a customer deliver on a backlog of orders is what moves automation the fastest. Delivering back-ordered product more quickly is the number-one driver of automation.

How can system integrators help with ease of use and technical support?

Salvalaggio: Design automation with operator intent in mind. Include automation as part of the design process. Look at how equipment should operate. It’s tougher to adapt a machine after it’s built. Someone has to operate that equipment all day long.

Kramer: Look at what automation if any do customers have in their facilities and ask how well suited it is to processes, technologies and people involved?

Gemma: It’s highly recommended that customers visit and get familiar with new technologies in the final stage of testing on our floor, rather than when it’s installed on their floor. Let’s make it a collaborative effort before it leaves our floor. Embrace automation as continuous learning to improve adoption and use.

Carson: The ROI clock starts when automation is installed on site. I agree it’s better for customers to adapt and learn before then.

Kramer: Many automated machines are in the corner with a tarp over them because operators didn’t embrace the technologies and weren’t connected to the design. Every installation needs to have to internal champions of automation, especially those working with it.

How do you know if your workforce is ready for automation? Are STEM programs helping?

Salvalaggio: Younger people may more readily adapt software-based simulation tools, because of greater software familiarity than older generations have. Some younger people may be lacking in machine building skills, so may gravitate toward software.

Kramer: It varies by individuals, and hands on experience is vital. Software is important, but if young people can take apart a dirt bike and put it back together, they’re a strong candidate for applying automation when they get to the plant floor.

Gemma: Many technology advances are rising from software. Assess skills of employees to help guide them through automation implementation. I’d like to see clusters of interest in automation driven by current policies to push wider skills training for automation.

Carson: Some estimate we soon will be 2 million people short of manufacturing skills required. Assess current and future team members to ensure you have talents and strategies to capture the skills needed.

Are companies ever too big or too small to automate?

Gemma: Automation ease of use is expanding. Collaborative robots can be easier for smaller companies to adopt robotic technologies, requiring less capital investment than traditional robotics. It’s helping that software and sensors communication more easily and are easier to use.

Salvalaggio: The automotive industry has done great things for standards and automation use. No matter the company size, they need a champion, and it helps to partner with a system integrator and automation vendors to help guide the way.

Shepherd: Pre-engineered solutions, many visible at the show, lower the cost of overhead involved with automation. To gain automation experience, we recommend the crawl-walk-run approach.

How do system integrators help after automation is running?

Kramer: We recommend regular maintenance, spare parts contracts and field service agreements. It’s important to develop or contract for expertise in your equipment before equipment fails.

Gemma: Full lifecycle management of equipment is available from many system integrators. We do it daily. Appropriate maintenance helps ensure you get more life from your automation with better and more consistent performance.

Salvalaggio: And it’s not just the automation, but the peripheral components and devices including power, cables, hoses and connections that can bring down equipment.

When should software backups happen?

Carson: Software value is increasing in industry on the digital side, including automation on site, in the cloud, AI use and regular backups are needed to protect assets.

Kramer: We’re owned and powered by Hitachi, a giant in data management. Digitalization can cost more than you think to get there.

Gemma: Some work to update automation documentation, but may not remember to update software documentation and backups. Backup software often.

Do you take videos of automation equipment?

Salvalaggio: Cameras to debug automation are invaluable for first 90 days of use. A third shift operator may not as familiar with automation, for instance, and can benefit from this help.

Shepherd: While many not be comfortable with use of video, it can improve company performance.

What are some “gotchas” involved with automation implementation?

Kramer: If automation isn’t appropriately designed for part variation, it’s just a sorter. Update documentation consistently for better results.

Gemma: Get with automation supplier early on for better consistency and get more attainable automation. Identify, position and operate better.

Carson: Focus on the 80% or 95% of cases. Trying to make automation handle everything can lead to scope creep. It rarely can or should do everything.

Salvalaggio: Automation is too complex if you do it all. Choose 80%.

Kramer: Operators often have the eyes, mind and hands to adjust processes as needed. If what is common knowledge on the plant floor operations doesn’t make it into the specification, the automation may fail. Tell your system integrator your growth plans so that can be designed into the automation for lower costs over time.

Salvalaggio: Part of the educational process is to tweak automation as needed. System integrators can help.

Audience questions included the following.

What are the most important characteristic of good system integrator customer?

Gemma: Collaboration with the system integrator to share details and vision and work through challenges as a partner, not as an adversary.

Carson: And to collaborate across all levels, from the operator to the executive-level sponsor.

Kramer: We look for what the customer seeking over a long period. Automation can be a challenge for the first time. Sometimes we may lose money on the first job. The specifications may there, but there may be gray areas to fill in.

Salvalaggio: Customers want their machines to work, and we can help by engaging from design all the way through project management, software and product development, learning with each other.

Shepherd: System integrators like to start at the beginning of engineering process to get the best technologies to help eliminate inconsistencies.

How can digital twins and virtual commissioning help?

Carson: System integrators can help make digital twins valuable. Next steps include autonomous decisions to improve automation. Computer-generated imagery (CGI) is for marketing, and a true digital twin can drive decisions to create value.

Salvalaggio: Animation versus validation: What value can digital twin software create for a factory.

Kramer: A large battery manufacturing installation in China used digital tools during COVID to install machinery we developed. It was a great example of successful software tools helping automation implementation.

Shepherd: Digital twins are on their way in with better graphics and simulation, higher accuracy and robotic simulations.

Gemma: Simulations help to finding problems in real-time closed-loop system before they go live on the plant floor.

Mark T. Hoske is editor-in-chief, Control Engineering, WTWH Media, [email protected].

KEYWORDS

Getting started with automation, system integrators

CONSIDER THIS

What help do you need with implementing automation, and how can a system integrator help?

ONLINE

Find more coverage by searching “Automate 2025” at www.controleng.com.

For more from Gemma, see related article from Automation 2025.

www.controleng.com/automate-2025-benefits-challenges-of-implementing-automation

See more from Salvalaggio.

www.controleng.com/digital-twins-advance-digital-transformation-control-system-integration