Digitalization: By integrating digital, physical and virtual realities, digital engineering redefines product development and manufacturing. Digital engineering accelerates development of next-generation smart products, services and operations.

Combining the digital, physical and virtual realms, digital engineering and enabling technologies are redefining how products are developed and manufactured. Digital engineering leads to next-generation smart products, services and operations that accelerate end-user value.

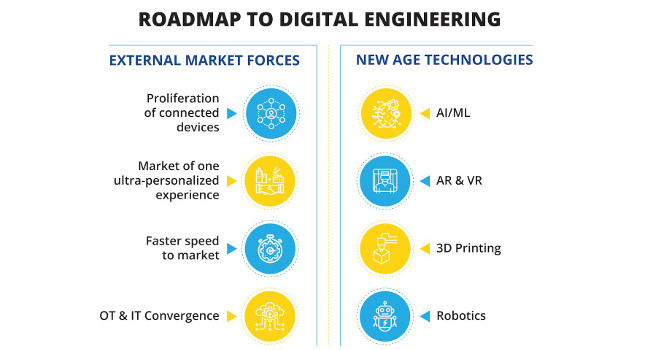

Technology is influencing our lives by changing lifestyles and behaviors. Within the industrial landscape, digital technology transformation is being called the fourth industrial revolution, or Industry 4.0.

Because of accelerated adoption in life and business, what’s visible now is just the tip of the iceberg. New applications emerge from affordable computing power, fast connectivity, cheap storage and high capability sensors. According to Gartner, there are likely to be 20.4 billion connected things in use worldwide by 2020, across all industries, including automotive, industrial products, high-technology, energy, utilities and more.

Digitalization allows customization to meet specific customer needs beyond one solution. Enhanced customer experiences include ease of usage, simplicity and interactivity. Customers see core product offerings and differentiating product attributes more quickly.

Digital engineering is assuming the primary position as the pathway to enhance and disrupt traditional processes and accelerate the technology landscape. While digital engineering captures data for business excellence, it also acts as a bridge that merges real-time processes with the digital spectrum.

Digital engineering defined

Consider digital engineering as the technological concept that enables development of smart connected ecosystem to enhance experiences and optimize functionalities. By combining digital, physical and virtual realms, digital engineering and related new-age technologies are redefining the way products are developed and manufactured for end consumers.

With increased research and development (R&D) and engineering implementations, digital engineering leads to next-generation smart products, services and operations to enhance end-user value.

For these reasons, digital engineering continues to be appealing the wider business ecosystem. For instance, Zinnov Research expects the global spend on digital engineering will jump from $223 billion in 2018 to $667 billion by 2023.

The scope of digital engineering spans the product lifecycle, including the concept phase to planning, through design, production, and monitoring products (including built infrastructure) over the service lifecycle.

Industry experts explained that customers across sectors seek to streamline platforms and want them to support every possible feature, while the user wants a unique set of features that adapt to changing needs. Data digitization and translating data into a service are becoming increasingly important. Deriving large amounts of data from various sources has become essential to generate tangible business value. That drive to create business value and facilitate an exponential digital transformation excites engineering research and development (ER&D) leaders globally.

Shop floor to top floor

In the last three decades, information technology (IT) infrastructure has greatly improved and digital transformation has made significant impact on organizations. The rapidly changing future requires a new kind of transformation that embraces IT and a new kind of engineering that enables personalized and optimized user experiences with the help of digital and emerging technologies.

The traditional gap between the “top floor and the shop floor” is blurring with new components and machines connected by the Internet of Things (IoT). Such connections can provide the deepest factory-floor visibility in an instant. Bringing “smart technologies” onto the shop floor of manufacturing enterprises has boosted efficiencies and cut costs for enterprises. These are among the major success stories of digital engineering.

Like manufacturing execution systems (MES), asset management services provide a backbone for smart factories. Such systems control the infrastructure that powers plants and keeps factory lines running without a glitch. Only in recent years have technology and business reasons compelled companies to work through operations technology (OT) and IT convergence. OT-IT technology integration is appealing because it helps avoid separation of technology areas and areas of authority and responsibility. An integrated process and information flow offers more opportunities, especially as more devices connect to the Industrial Internet of Things (IIoT) network.

Digital challenges, opportunities

Challenges exist for digital engineering practitioners. Because the movement is still at an early stage, many enterprises are struggling to scale digital engineering to desired levels and positively impact the business with top- and bottom-line growth.

Change management should be considered with digital engineering efforts because it can trigger organization-level changes.

Evaluating the fiscal feasibility of digital engineering requires linking change management to a validated business cause to ensure success. Measured parameters can include product, quality and sustainability, triggered by any of the three levers of people, process and technology. Digital engineering interventions remain human-centric. Artificial intelligence (AI), machine-learning (ML) algorithms, IIoT and all futuristic technologies should touch lives and contribute to building a sustainable and inclusive society. Success should be measured by return of value (ROV) and not solely on return on investment (ROI).

Finally, as organizations assume a data-driven identity, sustainable digital engineering advances need to extend beyond business intelligence to a more quantifiable cause such as bringing down the cost of inventory.

Eliminate the monotonous

Digital engineering is dissolving the boundaries of physical and digital worlds. These technology concepts can act as a catalyst and steering wheel and help eliminate monotonous and reiterated procedures and maximize cost effectiveness and efficiency. While the discipline is evolving, all technological giants have realized the large part it will play for the future of clients and business. The digital engineering revolution is here to stay and will gain momentum in the coming years.

Narayanan Ramanathan is global head-digital engineering, L&T Technology Services Ltd. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media, [email protected].

KEYWORDS: Digital engineering, digitalization

Digital engineering is enhancing and disrupting processes.

Convergence of information technology and operational technology helps.

Return of value should be considered along with return on investment.

CONSIDER THIS

Are you worried digitalization will allow your competitors to accelerate past your reach?