Emerson Process Management reports it recently completed a digital automation project at Shanghai SECCO Petrochemical Co.'s $2.7-billion, 10-plant ethylene cracker complex. SECCO picked Emerson in 2003 as its digital automation partner. The complex will annually produce 900,000 tons of ethylene and more than 2 million tons of other related petrochemical products for use in...

Emerson Process Management reports it recently completed a digital automation project at Shanghai SECCO Petrochemical Co.’s $2.7-billion, 10-plant ethylene cracker complex. SECCO picked Emerson in 2003 as its digital automation partner.

The complex will annually produce 900,000 tons of ethylene and more than 2 million tons of other related petrochemical products for use in plastics and synthetics manufacturing applications. The ethylene cracker is SECCO’s core plant in the complex. It’s reportedly the largest in China and one of the largest in the world.

Emerson says SECCO used its engineering and project management expertise to integrate and coordinate multiple suppliers, enabling complete construction in just 27 months, which was three months ahead of schedule. Startup of the ethylene cracker plant in March 2005 took just 10 hours and 45 minutes, which SECCO says was a world record for a project of this magnitude. SECCO is a joint venture between Innovene (formerly BP), Sinopec, and Shanghai Petrochemical Corporation (SPC).

“Our facilities and expert personnel at Pudong enabled us to partner effectively with SECCO, shaping a cutting edge solution,” says Sweechee Lee, Emerson Process Management China’s GM. “We were also able to call upon Emerson experts among our more than 4,000 global engineering and technical service professionals, particularly from centers in India and Singapore.”

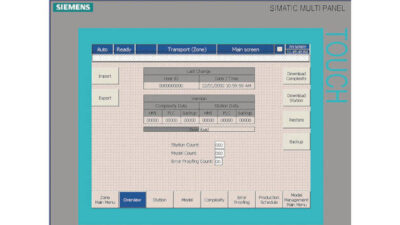

Emerson installed PlantWeb digital architecture throughout the SECCO complex, which contains 47,000 control loops, 40,000 instruments, and about 13,000 intelligent devices networked in the world’s largest FOUNDATION fieldbus installation.

SECCO adds that the integrated complex project also had no major accident and zero fatalities during construction, which included more than 50 million man-hours of labor. The site reportedly also included leading environmental standards.