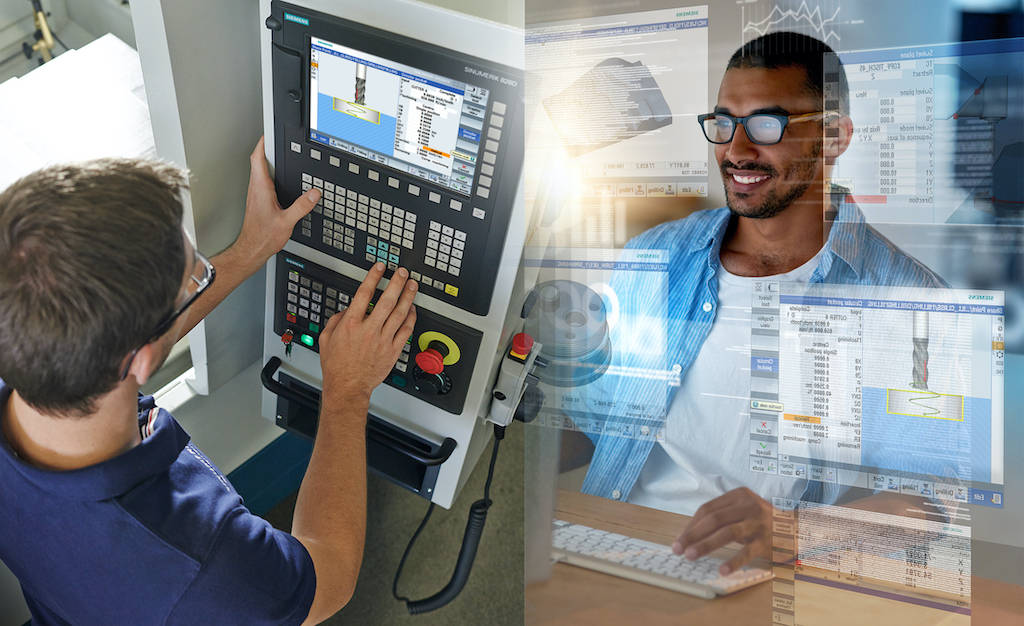

Programmers, operators and maintenance professionals can maximize results with a computer numerical control (CNC) to become indispensable on the shopfloor and maximize their return on investment (ROI).

Hands-on and online learning bring growth opportunities. Programmers, operators and maintenance professionals can maximize results with a computer numerical control (CNC) to become indispensable on the shopfloor and in their careers. Owners can maximize return on investment (ROI) in all areas: machines, people, and operations.

CNC professionals from around the world are taking advantage of Siemens free training paths: hands-on and online. And the reason is clear. Operators can gain the skills to maximize the output of the machine, increase their value to the business and further their career. Owners can skill up your staff to generate more shopfloor revenue.

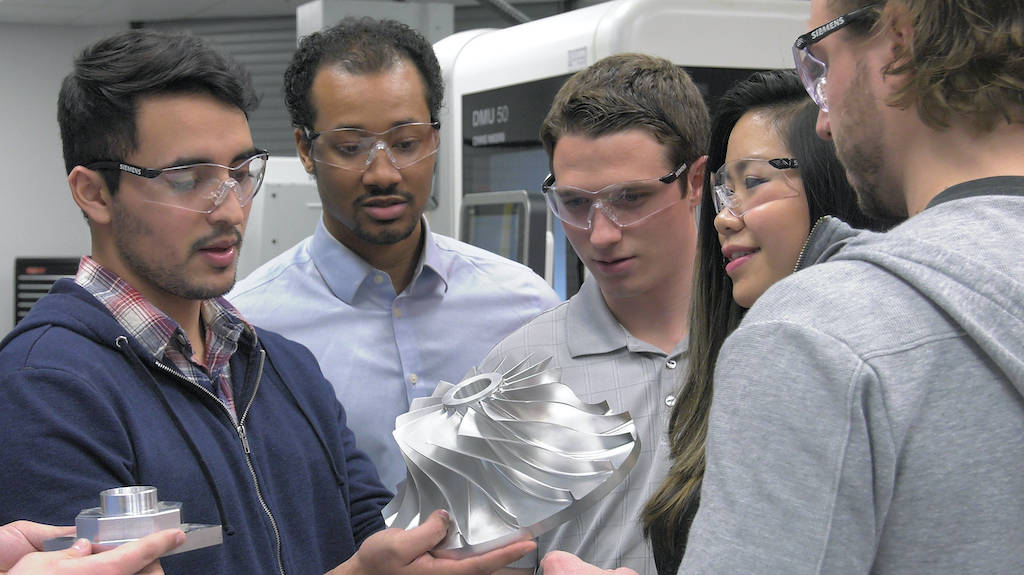

Hands-on learning at Siemens technical application center

“At the Siemens Technical Application Center, our goal is the education of CNC operators, programmers, and maintenance professionals,” said Randy Pearson, technical application center manager for Siemens. “We aim to enhance and expand the knowledge and capacity of our students on SINUMERIK controls. If you want to become a power user, we have the courses for you. We also provide essential training to machine tool builders, importers, and dealers.”

Through a team of knowledgeable instructors, users can gain first-hand experience working on the types of machines you will encounter in your own shop. A comprehensive schedule guides you on the journey from introductory classes through advanced 5-axis programming.

“Every month we provide level one courses on milling and turning,” Pearson said. “Level two courses explore advanced G-Code programming, while level three focuses on multi-axis programming.” Classes are taught by Siemens machining experts, bringing a wealth of real-world experiences to bear, using several different teaching methods:

- SINUTRAIN PC-based classroom sessions

- Simulator-based classroom training

- Hands-on machining using industry leading brands.

In addition, service and maintenance classes are available to teach personnel how to perform PLC and drive diagnostics, check the topology of the system, commission, and troubleshoot the system.

Online learning available

Getting to a Siemens training center may not always be possible for you. But you still have plenty of options. Live, online courses are presented monthly, which include insightful question and answer sessions. Courses are archived and available on-demand, so you can access them anywhere, anytime. Our ever-growing CNC online learning resources are updated with new and fresh courses often. Plus, for larger groups, custom online training sessions are available.

“Our online campus, featuring dozens of technical webinars, is located at usa.siemens.com/cnc4you,” said Chris Pollack, virtual technical application center manager for Siemens. “All of the topics that are covered in our hands-on classroom courses — such as variable-based programming, logic-based programming, and multi-axis milling and turning — are covered online as well.”

“We have a strategy for how we want people and manufacturing to excel,” Pollack said. “You may begin with a five-minute how-to video as an introduction. You will then be motivated to immerse yourself in a webinar or two and really start digging into a topic. You can follow that up by enrolling in a self-paced learning module or an instructor-led class to start engaging hands-on with the technology at a high level.”

The progression of learning

The curriculum not only provides users with hands-on experience using actual CNCs, but it focuses on many of the trends that are shaping today’s machining industry.

Courses are separated into four main categories: Milling, turning, general operations and maintenance/service. These categories provide everything programmers, operators, and maintenance staff need to advance their careers, and everything a shop owner needs to turn their shop into a competitive powerhouse.

Addressing CNC technology trends

Machine shops are finding that today’s digital-savvy workforce more readily interacts with controls that speak their digital language. The SINUMERIK CNC platform is based on a modern, app-like interface that is easily engaged shop-wide, from 3-axis all the way to full 5-axis machining.

Machine shops are addressing fierce competitive time and cost pressures. Training staff on mixed-technology machines that do the work of two or more machines simplifies scheduling, reduces setups, and accelerates production. SINUMERIK CNC simplifies the integration of automated processes, such as robotics, that allow you to do much more, in much less time.

Learning is vital to success

Give your career a boost. Move your company forward. Siemens makes it easy.

- Hands-on training courses available at our training centers include:

- Milling operations and programming, Levels 1 and 2

- Turning operations and programming, Levels 1 and 2

- 5-axis machining operations and programming, Levels 1 and 2

- Service, preventative maintenance and diagnostics

- Live online sessions presented every month

- On-demand learning sessions are available online.

– Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, [email protected].

ONLINE

See additional workforce development stories at https://www.controleng.com/system-integration/workforce-development/