System integrators discuss how to automate and the things system integrators look for and find during plant or facility walk throughs. It’s often during initial automation project design discussions when the most savings can be identified for the least cost. What don’t you know? See advice below.

Learning Objectives

- Explore what system integrators look for in a plant walk through.

- Meet and ask questions of the system integrators teaching the course on system integrator walk-throughs.

- Explore advice from system integrators related to automation efficiencies and tactics during a plant walk through.

System integration savings insights

-

Automation and control system integrators look for certain things when observing automation during in a plant walk through. Find out what.

-

Meet the system integrators teaching the course on system integrator walk-throughs.

-

Get a preview of some system integration plant or facility walk-through advice with a link to the Dec. 12 webcast for more.

A common cliché in automation and controls is to pick the low-hanging fruit first, meaning automate the easiest and most accessible applications as the first step. A Dec. 12 Control Engineering webcast, “What system integrators look for in a plant walk-through,” aims to answer the following questions.

Are you able to really see what may be done in an application that’s ripe for automation? Does the team that’s in the thick of things need a fresh set of eyes to see old processes anew?

System integrators discuss how to automate and the things system integrators look for and find during plant or facility walk throughs. It’s often during initial automation project design discussions when the most savings can be identified for the least cost.

What do system integrators look for in a plant walk through?

In the webcast, the following are learning objectives. Experts aim to:

-

Examine how, with the rate of technology advances, opportunities for automation advancement have changed in recent years.

-

Understand what control system integrators look for when they do a plant for facility walk through, seeking automation opportunities for potential clients.

-

Review why system integrator expertise (coupled with plant-specific domain expertise) can add tremendous value in the design and planning phase of any project.

-

Learn best practices related to identifying automation and controls projects that can deliver high return on investment by looking at examples.

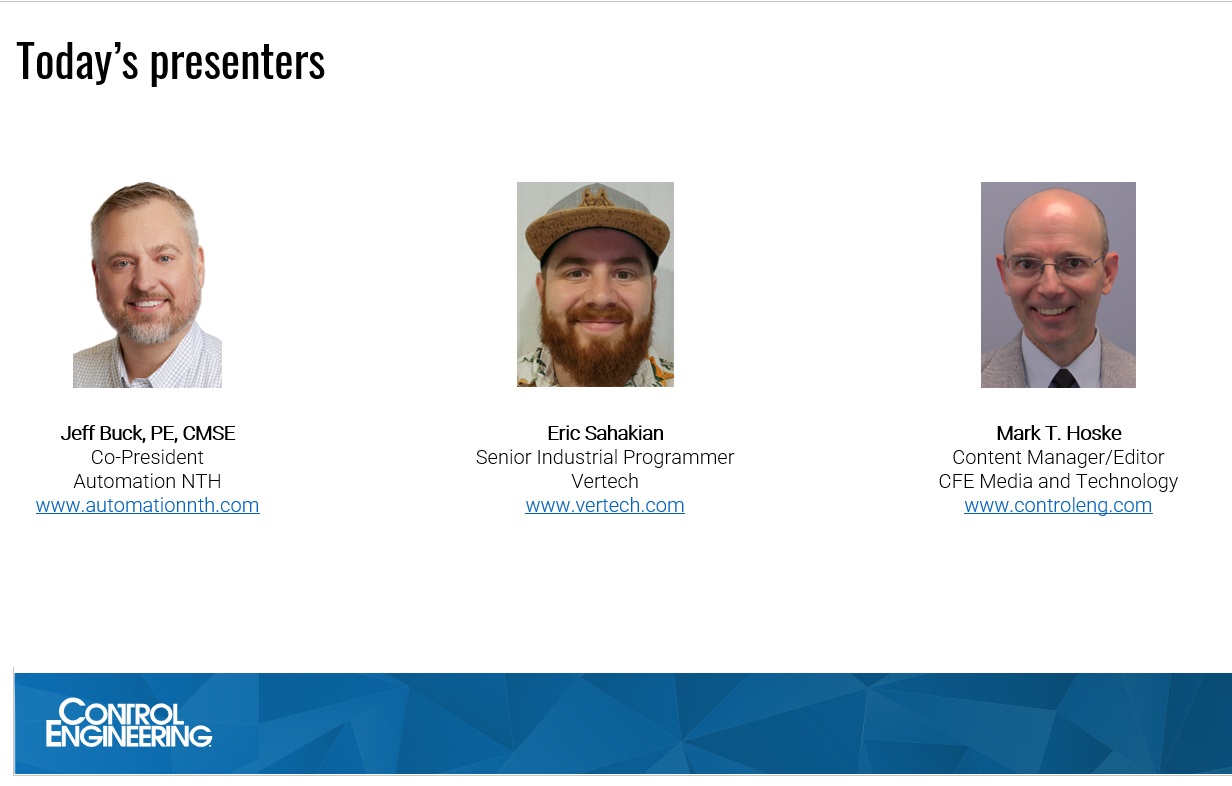

Meet the system integrators teaching the course on system integrator walk-throughs

Presenters in the webcast are:

Jeff W. Buck, PE, CMSE, co-president, Automation NTH, www.automationnth.com, oversees the technical and project execution aspects of automation equipment, ensuring that Automation NTH delivers innovative, high performing solutions to customers. As a registered Professional Engineer in the state of Tennessee and Certified Machine Safety Expert, Buck’s detail-oriented approach and skills in risk mitigation and project management has led to the successful delivery of hundreds of projects since he joined the company in 2003. Buck created and leads “NTH University,” the company’s training program for engineers. Earlier in his career, he worked through the major engineering roles of a systems integrator, including designer, programmer, project manager, and technical leader for large, complex automation systems, as well as vice president of engineering. He visited and worked in production facilities around the world in a variety of industry segments. Buck graduated with a M.S. in Mechanical Engineering, Automation and Robotics and a B.S. in Mechanical Engineering from the University of Tennessee.

Eric Sahakian, senior industrial programmer, Vertech, www.vertech.com, has a B.S. in Mechanical Engineering from Arizona State. He has focused on solid system function and user experience (UX), building long-term Ignition and enterprise solutions for dozens of clients over the past nine years. His comprehensive and custom manufacturing executive systems (MES) and supervisory control and data acquisition (SCADA) systems for Four Roses Bourbon provided full production tracking and overall equipment effectiveness (OEE) functionality.

Those listening live have the opportunity to earn a PDH credit. The webcast includes an audience poll question about a system integrator plant walk-through and a question-and-answer session at the end.

Practical plant walk-through advice to enhance automation

The system integrators provide practical plant walk-through advice for those seeking automation integration advantages.

Sahakian said areas of increasing attention for plants and facilities include Industry 4.0, better information flow from the plant floor to the boardroom and back, elevated cybersecurity, wider use and integration of artificial intelligence applications (AI), robotics and edge computing. While some plants have in-house teams to implement optimization projects and automation upgrades, good system integrators will look out for best interests of a client, especially over many months or years for large-scale projects. Initial planning can identify and mitigate gaps early for long-term success.

Preparation before a walk through a plant, according to Buck, includes listening to customer concerns and asking about safety requirements, including personal protective equipment and health and safety concerns. Reviewing documentation such as schematics, machine drawings, process overview and photos and videos can be helpful, along with data on metrics, such as overall equipment effectiveness (OEE) or any known issue.

Buck said the actual walk-through requires using all senses, listening to those in the plant as well as equipment. Observe cleanliness, layout, process flow, level of safety implementations, staff skill levels, complexities of processes and automation and wear patterns. Noticing odors of concern, such as burning or fumes, can help. Feeling vibration or impacts can help address longer-term wear, maintenance and safety issues.

Mark T. Hoske is content manager, Control Engineering, CFE Media and Technology, [email protected].

CONSIDER THIS

Are you sure you’re taking advantage of the most practical plant automation opportunities?

ONLINE

Register for the Dec. 12 webcast on what system integrators look for in a plant walk-through, archived for a year, here.