Measurements and information sharing are important for meeting industrial sustainability goals: If an organization is struggling to meet 2025 goals, then 2030 is at risk. Advanced technology integration of automation and control systems, artificial intelligence and digital transformation can help adjust processes and empower people to move more quickly.

Learning Objectives

- Understand how digital transformation, automation and control systems can help with ESG improvements and what growth opportunities may apply.

- Learn how manufacturers can achieve industrial sustainability goals more quickly with the right technologies, people and processes.

- Examine if manufacturing as transparent as it needs to be and find what needs fixing, fix it and fix it to continue to accelerate industrial sustainability progress.

Industrial automation, sustainability insights

-

Digital transformation and automation can help with ESG improvements and take advantage of related growth opportunities.

-

Manufacturers can achieve industrial sustainability goals more quickly with the right technologies, people and processes.

-

Manufacturing sustainability efforts benefits from transparency to find what needs fixing to continue to accelerate industrial sustainability progress.

By 2030, many industrial companies are aiming for zero: zero harm to the environment, zero waste, zero net carbon and achieve step performance gains in productivity, and discussions at LNS IX2023, The Industrial Transformation Event aimed to help. The in-person and online event from LNS Research included a panel discussion covering a range of industrial competitiveness topics, including sustainability and how automation can help.

-

Allison Kuhn, research analyst, LNS Research, moderated. Panelists were:

-

Ellis Jones, sustainability leader and independent director, TimkenSteel Co.

-

Mike Carroll, vice president, innovation, Georgia-Pacific

-

Tom O’Reilly, vice president, sustainability, Rockwell Automation.

Digital transformation, automation and control systems, ESG improvements

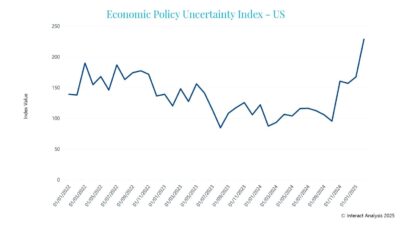

Kuhn noted that digital transformation initiatives better equip top manufacturers to address trends affecting businesses today. Sustainability efforts help manufacturing stakeholders, and they’re the right thing to do, she said. Environmental, social and governance (ESG) requirements interlink and are centered around money, but ESG can be redefined to be easier, better and safer, less politicized, focusing on what’s most important (Figure 1), Kuhn suggested. She asked the panel what advice they could offer for improving industrial ESG initiatives.

Jones said when he was a chief executive officer, he tried to connect and integrate sustainability into other initiatives. Sustainability cannot be separate from other business.

“This is the work we do. It’s not separate. You have to connect and integrate sustainability as an organization,” Jones said, noting that the company’s business strategy needs to be a sustainable business strategy. “You cannot do it overnight. It’s now part of your business.”

Jones said thinking ahead should be a matter of course for today’s industrial leaders. “If leaders aren’t focusing on tomorrow problems today, they’re already behind.”

O’Reilly said that for Rockwell Automation sustainability has been integrated in the business for a long time, and all stakeholders are actively involved at what the company is doing and what it needs to do differently. That integration removes any politics from sustainability efforts.

Growth opportunities: Industrial digital transformation applied to ESG

Kuhn sees incredible growth opportunities related to industrial sustainability and asked the panel’s views.

O’Reilly said the journey to zero is different than other initiatives requiring broader, more integrated technology applications.

Carroll said companies need to consider how embedded sustainability is in their strategies and identify and apply the resulting goals. He suggested developing a strategic roadmap of how to get, there year by year, with programs and measurements to achieve goals, not just aspire to them.

Jones said any industrial sustainability story has to be transparent. Lay out how you’re going to get there and how to structure the organization to make it happen. Integrate sustainability into all functions, including capital planning. Know your organization’s sustainability maturity level, and all involved should know their roles to make it happen, with metrics to show progress toward the goals.

Carroll said that integrated industrial sustainability doesn’t change what gets done, just how it’s done, where appropriate. “We don’t have to wait until 2030 for machines to help make decisions to optimize production and where to put capabilities to close the gap. We’re already doing that. Now we have to scale for the enterprise,” Carroll said. Sustainability functions and processes already are real, and if you’re not doing them now, it may be too late to meet 2030 goals, he suggested. Collective knowledge in a company can make smarter future decisions. Digitalization helps with applying power of compute relative to data, knowledge and assets, closed loop, in real time to meet sustainability goals, Carroll said. Transparency of assets is required to get things made where they’re needed for most the most sustainability progress

How to achieve industrial sustainability goals more quickly

Kuhn asked how to make better progress toward sustainability goals, applying innovative solutions, eliminating tedious data collection and analysis to get actionable insights more quickly.

Carroll said, “Many want to sell me actionable insights. We know what our problems are. How do we get past so many issues for prioritization?” Any technology application has to fit into existing systems. Also, delivery and use of the application needs to differ for 2-year employees versus 30-year employees. The operations model needs to change, Carroll said. A different level of automation, control systems and intelligence is needed to deliver insights at right place right time. The world’s changing rapidly, and we need to adapt to it. “If you wait too long to change, your assets will have someone else’s name on them,” Carroll warned.

Industrial sustainability: The right technologies, people, processes

Kuhn said technologies are enabling step change differences that didn’t seem possible 20 or even 5 years ago, but without the right people and processes, the technologies won’t work. Have organizations waited too long to meet sustainability goals?

O’Reilly said that in manufacturing, some, especially at senior levels, believe that sustainability efforts hurt productivity. We need to continue to educate that we can drive both productivity and sustainability together.

Jones said ESG goals are difficult: Zero emissions, zero injuries and zero waste are hard. Expressing doubt can be a transparent way for leaders to say more effort is needed. Many companies are confident in their strategies, but have some gaps to work through. Challenges are OK. Transparency opens an organization up to get help. Although the legal team will tell leaders they cannot discuss gaps and challenges, a great boss will not hide secrets.

Carroll said everyone wants generative artificial intelligence (AI), but many in senior management do not know how to apply it in practical ways. Being good at generative AI will help and enable, but won’t necessarily save those who use it. It is data science, but generative AI cannot do what some say it can.

Is manufacturing as transparent as it needs to be for sustainability?

Kuhn asked the panel if manufacturing needs to be more transparent than it is about application of digitalization and automation and control systems for sustainability and other ESG goals.

Carroll said manufacturing has been in the shadows for a very long time. The enterprise has an expectation leaders should know what’s going on. Assets provide data, but often provide data in hindsight, which isn’t as useful as it should be.

Jones said that if you’re managing an industrial site, you have to win the shop floor, especially with sustainability initiatives. How? Even winning over union leadership about technologies doesn’t matter if you don’t win shop floor. What do operators need to win, daily? Transparency is not easy. Plant floor personnel will call you on it if it’s missing.

Find, fix and fix again: Industrial sustainability progress

Kuhn notes that people cannot fix what they don’t know and agreed that sustainability has to be driven by the shop floor, not just imposed on the shop floor. How does sustainability get embedded in daily activities to create value? How can manufacturing move from a compliance-based culture to one who knows why sustainability changes are needed?

O’Reilly responded that manufacturers need to drive sustainability and productivity together, changing sustainability from a requirement to an opportunity. A sustainability strategy has to be part of the core mission. Get technology the right way. Have the supporting technology infrastructure to support people and processes the right way (Figure 4).

Jones said moving toward sustainability goals requires a process with reporting. The organization needs a hero driving it, and it needs to be functionally integrated at every level: Product development, recruiting, incentives and compensation systems, along with engineering and material science mindsets for sustainability.

Carroll said people in the organization have to think what “good” looks like for sustainability. They may leave if they don’t like what’s required to get things done.

Jones said one way to approach sustainability is to look at how safety has been implemented to win the shop floor. When there’s an incident, a process is in place to analyze. How can we get the sustainability work get done? I’m in the firing line 5x a shift to get the work done, he noted.

How can industry rebound from sustainability failures and meet goals?

Kuhn asked how we can learn from the past to improve the future.

Jones said leaders often have a long list of objectives and will fail at some of them. He recalled a time when observers determined that one department had too many shifts. Advice from the plant floor was that perhaps the decision was made without having all the data. Moving from three shifts to two may have looked feasible on paper, but doing so shut the plant down and required scrambling to recover.

Carroll said he worked through challenges when consultants changed a product to save money. People with 35 years of experience warned not to do it, because failures would result. Today, he worried out loud, some organizations may not have front-line people with that level of advice and experience to offer.

O’Reilly noted that sustainability reporting is required at all levels, not just for investors, but also for customers and employees. Benchmarking against the best helps at all levels, with guidance from a variety of sources, including LNS Research, he said. Greater transparency about progress has put the organization in a sustainability requirements state of mind, O’Reilly added.

Mark T. Hoske is content manager, Control Engineering, CFE Media and Technology, [email protected].

CONSIDER THIS

Are you integrating enough automation, adjusting processes and giving people tools to identify, meet and exceed sustainability opportunities?