The continued operation of aging manufacturing lines poses a threat to production, safety and cybersecurity. However, these issues stem primarily from the aged control system and not the operating mechanical equipment. By upgrading the controls system while retaining the existing mechanical systems, the line can be modernized while minimizing cost, time and risk.

How long can a production line keep running on outdated control systems?

For many manufacturers, this question’s urgency increases with every unplanned shutdown and each unavailable spare part.

Plant managers are aware that intermittent downtime, scarcity of spare parts, cybersecurity risks and limited integration capability are some of the challenges associated with operating older control systems. However, they are also constrained by tight budgets and limited shutdown windows, each impacting their ability to improve a line’s overall equipment effectiveness (OEE) metrics.

Interestingly, when the control system has become obsolete, it’s common for a legacy line’s mechanical equipment to remain in good working condition with many years of serviceable life remaining. As a result, by focusing investment towards upgrading the control system, the entire line can be modernized with far less risk, downtime and cost compared to full replacement. When planned carefully, a controls upgrade can transform line reliability, data visibility and long-term scalability without the expense of starting over.

Aging control systems are a weak link in industrial operations

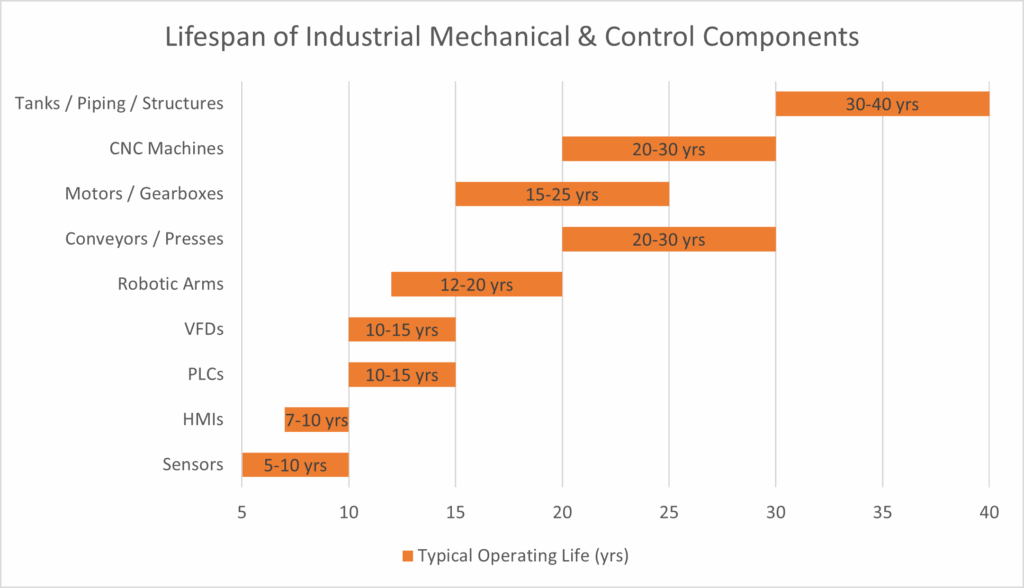

Why do control systems become the limiting factor in otherwise functional production lines? The typical life span of various industrial mechanical and control system components (see Figure 1). Devices that incorporate more electronics tend to have shorter operating lives, such as sensors, human machine interfaces (HMIs), programmable logic controllers (PLCs) and variable frequency drives (VFDs), compared to those that have less or none, such as computer numerical control (CNC) machines, motors/gearboxes and conveyors/presses. This relationship is not coincidental.

Electronics-based controls including PLCs, HMIs and drives degrade over time due to the failure of their small-scale electronic components and assemblies and general obsolescence of internal microchips. Within 10 to 15 years of service, these devices begin incurring increased fault rates and spare parts become hard to obtain. The resulting downtime is often difficult to diagnose and resolve, particularly when the failure is intermittent or associated with low-level hardware issues.

When a module fails, it must be replaced to return the line to production. As control systems age, sourcing these parts becomes progressively more difficult. Within 10 to 15 years of its final production run, original equipment manufacturers (OEMs) eventually cease all spare part support and render the product fully obsolete. At that point, manufacturers resort to eBay-type resellers, raising both cost and risk.

How aging control systems leave companies vulnerable

Compounding the issue, OEMs typically discontinue firmware support for legacy systems within a similar timeframe. Without updates, any new cybersecurity vulnerabilities remain unpatched, leaving critical infrastructure exposed.

Finally, aging control systems frequently cannot meet the demands of modern automation. Many cannot support coordinated motion in robotics or packaging lines, nor can they handle real-time data collection for OEE tracking and quality monitoring. As a result, obsolescence not only increases downtime risk but also limits a plant’s ability to modernize.

These factors collectively make legacy control systems the weakest link and the primary target for modernization. Control System Upgrades: A Strategic Investment in Line Longevity offers a deeper technical explanation about the specific failure mechanisms and obsolescence risks of older control systems.

Mechanical equipment remains reliable

While aging control systems present numerous complex challenges, it’s common for the line’s mechanical equipment to remain in good condition considerably longer. In fact, the serviceability of a production line’s mechanical equipment can span multiple control system upgrade cycles.

For example, consider a conveyor system. Bearings and rollers may require replacement, but the frame, gearboxes and other mechanical drive components often remain in service for decades with routine maintenance.

Degradation of mechanical assemblies tends to be gradual, predictable and easier to manage through standard maintenance practices. Furthermore, mechanical systems rarely become obsolete. When parts such as shafts, couplings or bearings wear out, replacements or repairs are typically straightforward, with parts readily available or able to be fabricated. Many mechanical systems are designed to be overhauled or rebuilt multiple times throughout their service life, often lasting several decades.

The business case for control system upgrades

Because a line’s mechanical systems face minimal obsolescence concerns, it can usually be modernized by upgrading the control system. Consider the following benefits of completing controls upgrade over a full line replacement:

- Lower capital cost spread over phases: Replacing the control portions of a production line, including PLCs, HMIs and motor drives is far less costly than installing an entire new line. In addition, when multiple phases are used to complete the upgrade, the project’s cost can be distributed over a longer timeframe, rather than one large upfront investment.

- Shorter project lead time: For a controls upgrade, standard PLCs, HMIs and I/O modules can be sourced and installed much faster than equipment for an entirely new line.

- Reduced disruption to production during installation: Phased upgrades can be aligned with existing shutdown windows, with production resuming between phases. Virtual commissioning techniques allow engineers to digitally test and refine control software in advance, reducing installation risk and downtime.

- Preservation of proven mechanical assets: Maintaining the existing mechanical portions of a production line reduces installation and integration risk and maintains system familiarity for operator and maintenance staff.

- Harvesting of spare parts: As legacy controllers are replaced, their parts can be saved for any other lines still operating the same control systems.

In addition, an upgraded control system provides the foundation for modern production line capabilities, including:

- Faster cycle times

- Better diagnostics and troubleshooting information

- Remote monitoring and support capabilities

- Better cybersecurity protection

- Access to real-time production data for analytics tools and digital twin development

- Simplified integration with modern SCADA, MES and enterprise systems

Realizing these benefits requires significant planning to ensure the upgrade is successful. The following section outlines key preparatory steps.

Preparation for a controls upgrade

Because a control system’s primary function is coordinating and directing the manufacturing process, a successful upgrade requires a holistic understanding of the existing system. The control system is connected to every element of the production line, including mechanical equipment, sensors, HMIs and switches. Preparation for a controls upgrade involves gathering documentation, analyzing the process, planning for software migration and addressing cybersecurity posture, as elaborated upon below:

Communication protocols

Identify all communication protocols used by connected equipment to ensure compatibility with the new PLC and prevent connectivity issues. If any devices are incompatible, identify any protocol conversion gateways that can support the equipment.

Design documents

Obtain existing electrical and mechanical prints to understand how equipment is interconnected within the current system. If the prints are unavailable, physically trace the electrical and mechanical interconnections to map the system.

Sequence of operations

Understand the order of operations within the process. Video recordings of the current system can be used to help understand the existing source code by matching observations with the control logic.

Software migration

Assess whether existing control logic can be translated or should be rewritten. This depends on the code’s quality, clarity and compatibility with the new platform.

Cybersecurity posture

Evaluate the operational technology (OT) network’s current and future cybersecurity needs, especially as modern control systems incorporate remote access, real-time data collection, system monitoring and diagnostics and integration with plant-wide software systems.

For readers seeking a more in-depth guide to upgrade preparation, a detailed overview of planning strategies is discussed in this article: Strategies and Preparation for a Controls Upgrade.

Control systems upgrades extend the life of a production line

A recent project completed by Patti Engineering demonstrates how a targeted controls upgrade can resolve long-standing issues and extend the useful life of an existing production line.

Problem: Extended downtime, difficult restart, no spare parts

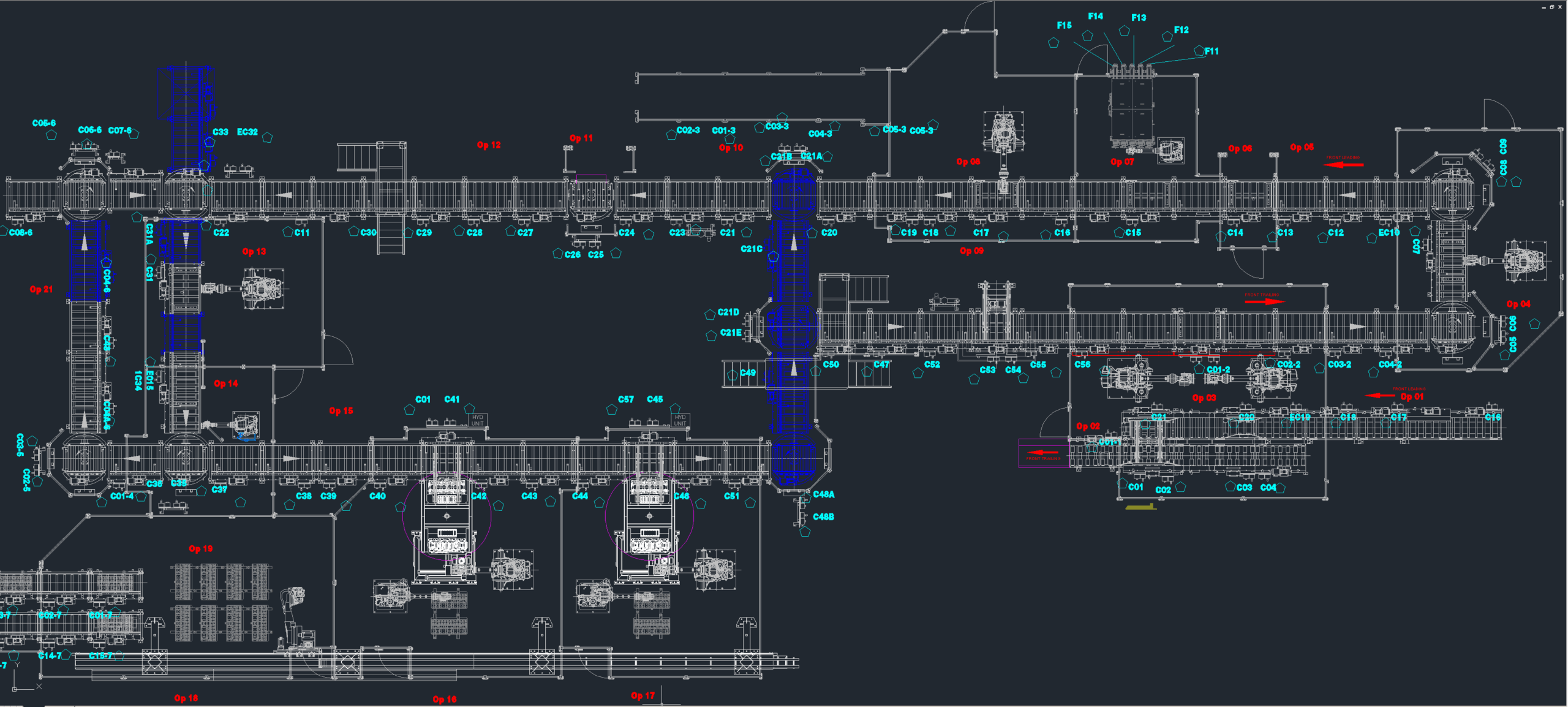

A leading manufacturer’s heavily used, aging engine assembly line was controlled by an older Allen-Bradley PLC and incorporated over 100 independent conveyor sections, 12 robotics stations, plus hundreds of sensors and other additional equipment (see Figure 2).

The manufacturer had been facing an increasing frequency of unexplained downtime. Compounding the issue, the existing controls software did not include sufficient diagnostics or alarming, making troubleshooting difficult. When the line failed, it often took several days to find the underlying cause and restart production. Spare parts for the controls systems were no longer available from the OEM and could only be found via highly unreliable sources –– primarily eBay.

After several multi-day downtimes and expensive emergency support calls to restart the line, the manufacturer recognized that addressing these issues could no longer be delayed.

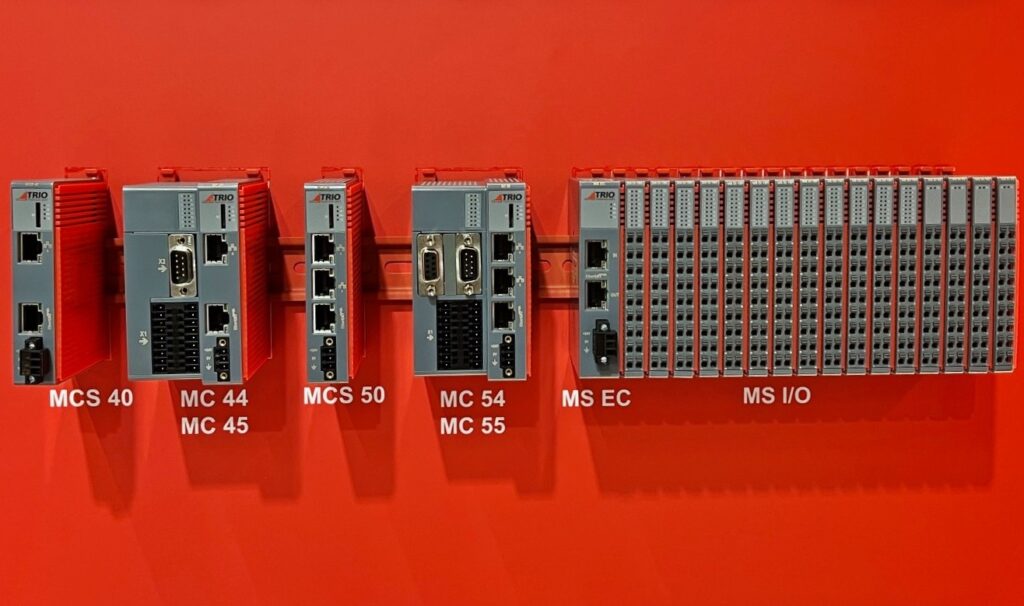

Solution: Phased controls upgrade with software rewrite

Since the mechanical equipment was in good operating condition, Patti Engineering recommended a targeted controls upgrade with a complete software rewrite and a phased upgrade approach to minimize interruption to production.

Given the line’s size and complexity, Patti Engineering completed the upgrade during 15 phases aligned with scheduled shutdowns, allowing production to resume between installations. Virtual commissioning was used extensively to model and simulate the line’s operation to verify the new software’s functionality ahead of each phase of installation.

Results: Increased uptime, better diagnostics and fault recovery

In addition to eliminating immediate risks tied to obsolete hardware, the upgraded control system resolved the manufacturer’s downtime issues and dramatically improved fault recovery due to better diagnostics. Additionally, the new control system simplified integration with plant-wide platforms.

The case for updating control systems

While legacy control systems pose significant production and cybersecurity risks, full line replacement is not always necessary since mechanical equipment typically outlasts the controls system by decades. By focusing upgrade efforts on the control system, manufacturers can preserve existing mechanical assets while modernizing operations for better performance.

In addition to reducing immediate risks, modern control systems support faster cycle times, robust data collection capabilities, advanced diagnostics and analytics, remote monitoring and easier integration with plant-wide platforms. Investing in a controls upgrade improves production reliability and productivity, supports long-term scalability and positions manufacturers for future growth.

Sam Hoff is founder and chief executive officer; Nikhil Niphadkar is an engineering team lead and senior controls engineer II, both at Patti Engineering. Edited by Sheri Kasprzak, executive editor, Automation & Controls, Control Engineering, WTWH Media, [email protected].