Interview, questions and answers: L&T Technology Services launches new engineering design center in Plano, Texas, to create more than 350 high-skilled jobs in artificial intelligence (AI), digital engineering, cybersecurity and smart manufacturing solutions.

Engineering design services insights

- L&T Technology Services launches new engineering design center in Plano, Texas, near Dallas, to create more than 350 high-skilled jobs in artificial intelligence (AI), digital engineering, cybersecurity and smart manufacturing solutions.

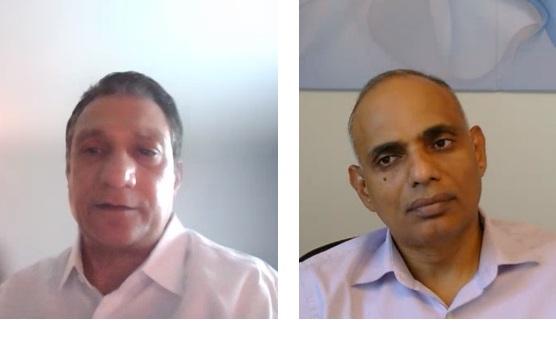

- Control Engineering interviewed two LTTS experts about how engineering design services can help industries with automation.

- More details about the LTTS Plano engineering design center are provided.

A new engineering design center from L&T Technology Services (LTTS) aims to advance the factory of the future for Industry-4.0-based digital manufacturing, real-time railroad track inspections, wireless charging and battery management systems, artificial intelligence (AI) for Industry 4.0 and smart cities and software-defined imaging using AI for advances in medical technologies. A Control Engineering interview with LTTS executives on the June 26 facility inauguration, along with more details, follow below. Answers are lightly edited for length and clarity.

Answering questions about the LTTS design center in Plano, Texas (near Dallas) are:

- Alind Saxena is LTTS executive director and president of mobility and tech.

- Bhanu Gopalam is LTTS chief delivery and strategy officer and head of LTTS U.S. design centers.

Control Engineering: Please introduce the L&T Technology Services design center

Saxena: About 55% of our business comes from North American-based clients. We have a global delivery model, so we deliver from everywhere. We have more than 2400 employees, mostly engineers, in North America [more than 24,250 globally] and in North America, we work from various centers, including other design centers and customer locations.

Texas is not new for us. We now have close to 400 engineers working in Texas. In Houston, we work with oil and gas and other organizations. We have set up our centers around customers to help us get better insights and create a collaborative working environment.

LTTS tech centers and engineering design center locations become part of a rich ecosystem of customers, talented people and universities. Work at Plano includes AI, digital manufacturing and cybersecurity. In addition, we have plans for a security operations center (SOC).

Gopalam: With technologies, we offer 24/7 services, supporting customers around the clock, serving industrial products, medical devices, transportation, telecommunications, high-technology and process industries.

Saxena: The immediate focus for Plano will be AI, digital manufacturing, server security along with aerospace. This is an area of the country that’s growing in aerospace and defense as well, so in Plano, we have an ITAR setup. [U.S. government International Traffic in Arms Regulations (ITAR) control the import, export and transfer of defense-related items.] There are very specific solutions that we are going to bring in for co-engineering efforts with customers. The facility will include an experience zone where customers get a look and feel for solutions, to do some product testing and show results.

Control Engineering: LTTS has other engineering design centers in North America?

Saxena: We have quite a few across North America, supporting major customers and industries, including Houston, Peoria and Rockford, Illinois [near Chicago], in New Jersey, in the Bay Area of California, in Dublin, Ohio, and in Canada. Another is planned for the West Coast. [As of March 31, LTTS had 23 global design centers, 30 global sales offices and 108 innovation labs.]

Control Engineering: Can you provide examples of work at the Plano engineering design center?

Gopalam: Cybersecurity is among specific things we’re doing here, along with smart manufacturing and connected factories. One manufacturing customer has around 400 sites globally, and we’re making them a connected factory. Interconnectivity services push data to the cloud and where needed, a model we are trying to build across industries. For a medical customer, we’re using AI-software-defined capabilities to increase diagnostic imaging using Nvidia tools.

Saxena: We also are working in the rail industry on advanced track inspection capabilities using an AI-based tool and imaging technology. It will help railroads detect problems such as crack and abnormalities, before they become really big problems.

Gopalam: We are bringing expertise on smart cities, integrating with smartphones and smart infrastructure, including traffic management and crowd management.

Control Engineering: How do customers know they need engineering design services?

Saxena: When we talk to customers, it’s about being able to solve particular problems or move in a particular direction. Look at the most important thing that needs solving. We can help bring in a technology that works as a differentiator to them in a key area. Traditional industries may not have the ability to incorporate new technology not used before. Having design centers close to our customers, we are able to put those teams together in co-innovation centers for design engineering, solution centers and test setups to show how technologies can make things different. Is very valuable and forward-looking for product development.

On the manufacturing side, there’s movement to manufacture more in North America. A way to work around of higher costs is to look at doing things much more effectively and efficiently in an optimized way.

One way is for assets to do multiple products in the same area. The only way to do that cost-effectively is to simulate, analyze, test scenarios and automate as much as possible. The teams we have are in the center of that. The key to a successful engineering center is being able to sit with customers, have those discussions, look at the results in simulations, ideate and do the what-if analyses.

Gopalam: We can add-on all the services offered in a multi-vertical scenario, bringing industry experience and expertise from other verticals into new workflows. For example, often we have already have done something on the desired technology, where we can take it to customers adapt to move beyond manual manufacturing. We are able to showcase automation technologies, collaborate, pilot them and roll them out.

LTTS engineering design center, Plano, Texas, inauguration

More information about the engineering design opening from LTTS follows. The facility opened with capacity for 100 engineers and aims to create more than 350 high-skilled jobs in core business segments including mobility and tech. The inauguration event included John B. Muns, Plano mayor; Tim Graham, vice president at Caterpillar; Manjunath Chenneerappa, honorable consul general of India in Houston; and Alind Saxena, LTTS president and executive director of mobility and technology. During the inauguration, engineers from LTTS demonstrated capabilities in:

- Factory of the future for Industry 4.0-based digital manufacturing

- TrackEI from LTTS, a real-time railway track inspection tool

- The LTTS iDriVe framework with autonomous driving and autonomous driving assistance systems (AD/ADAS), wireless charging and battery management systems

- Fusion platform from LTTS to leverages AI to deliver real-time insights for smart cities and Industry 4.0

- Software-defined imaging, an LTTS AI-driven technology using NVIDIA’s Jetson platform to enhance precision and efficiency in endoscopic procedures and make procedures more affordable.

In a separate statement, U.S. Senator Ted Cruz said, “L&T Technology Services has been an example of engineering innovation and a provider of jobs here in Texas. This new center is a testament to your unwavering commitment to excellence, ingenuity and the future” of the state.

Mayor of Plano, John B. Muns, said, “This center represents innovation at its finest and marks an important step forward for our region. With 100 professionals to start and plan to grow to over 350 engineering jobs, LTTS is not just creating opportunities, they are helping shape the future of advanced technology development and smart manufacturing.”

Congressman, Pat Fallon, 4th District of Texas, said the center adds to area “innovation and high-tech excellence, bringing over 350 new-age engineering jobs that will fuel growth in smart manufacturing and digital transformation.”

Saxena said the opening brings LTTS “innovation closer to our clients across all major segments and industries that we serve.” The center enables the LTTS “global delivery model, with proximity to our clients, while working closely with local partners and talent to co-create industry-defining solutions.”

Mark T. Hoske, editor-in-chief, Control Engineering, WTWH Media, [email protected], conducted the interview. The article includes information and photo from an LTTS news release.

More on smart manufacturing from LTTS and Control Engineering

https://www.controleng.com/unlocking-smart-manufacturing-roi/

More on cybersecurity from LTTS and Control Engineering

https://www.controleng.com/six-ways-to-improve-cybersecurity-barriers-vs-resiliency-2/