Three product lifecycle management (PLM) software vendors, Dassault Systemes, Oracle, and Siemens PLM Software, announced new or upgraded products, each promising to increase productivity, creativity, and profits for users. Autodesk is offering a technology preview of its history-free modeling technology, Inventor Fusion, starting June 25.

Three product lifecycle management (PLM) software vendors, Dassault Systemes, Oracle, and Siemens PLM Software, announced new or upgraded products, each promising to increase productivity, creativity, and profits for users. These PLM software releases represent significant investments in products, people, and lifecyles .

In addition, Autodesk announces today, June 24, that its history-free modeling technology, Inventor Fusion, will be available as a technology preview on Autodesk Labs starting June 25. Dassault Systemes, Oracle, and Siemens made announcements on June 22 and 23.

– Dassault Systemes (DS) launched V6R2010 , the latest PLM release, adding 42 new V6 products supporting business processes in all industries with V6 PLM Express tailored for mid-market businesses and small teams within large organizations.

– New release of Oracle Agile Product Lifecycle Management (PLM) for the enterprise "helps mitigate risk, reduce costs and increase user productivity," the company says.

– Siemens PLM Software launched Teamcenter 8 and Tecnomatix 9 , with a focus on productivity, lowering costs, and boosting revenue.

Dassault Systemes V6 R2010: 42 new products; Renault; PLM Express mid-market offer

Dassault Systemes (DS), a leader in 3D and Product Lifecycle Management (PLM) solutions, launched V6R2010, the latest release of its new platform, including 42 new V6 products supporting business processes in all industries. DS also introduced V6 PLM Express, tailored for mid-market businesses and small teams within large organizations. V6R2010 also includes groundbreaking direct modeling capabilities and realistic simulation solutions for non-experts, company says.

Odile Desforges, EVP engineering and quality, Renault, comments: "With the objective to transform our engineering processes worldwide, we needed to replace multiple existing solutions with a single, integrated and globally deployable one. We also wanted to concentrate on collaborative engineering for improved efficiency. After about one year of testing, we chose the full V6 portfolio because its integrated PLM environment perfectly responded to our requirements in terms of real-time collaboration and online-enabled design." Desforges says Renault will deploy Dassault Systemes’ V6 solutions worldwide for the development of future engines and cars from mid-2010. He likes the "scalability and openness of the V6 platform, its out-of-the box configurations and its easy-to-use intuitive V6 interface." V6’s inherent integration to the supply chain allows seamless collaboration with suppliers, he adds.

In recent months Dassault Systemes’ V6 collaborative platform has been widely adopted in multiple industries such as Apparel (Guess, UnderArmour, Trent Ltd.), Consumer Packaged Goods (Procter&Gamble), Life Sciences (Beckman Coulter), High Tech (Lexmark International, novero), Semiconductor (Dialog Semiconductor, INSIDE Contactless), Energy (Oceaneering, Stork GLT), Aerospace (Piaggio Aero Industries, Eaton Aerospace), Automotive (Eaton, Great Wall Motors, Johnson Controls), Business Services (TÜV Rheinland) and Construction (Skanska), DS says.

V6R2010 opens up key PLM 2.0 values to the mid-market, says DS, including real-time seamless collaboration, online-enabled design-anywhere functionality, and one, open scalable platform, in a pre-packaged, ready-to-use environment engineered for rapid deployment.

Release 2010 and its mid-market solutions:

– Advance the simplicity and accessibility of PLM 2.0. PLM Express’ role-based selections of the full V6 portfolio and its out-of-the-box configurations make the solution easy to buy and implement.

– Allow easy collaboration with OEMs because all V6 solutions share the same interface and data model, supporting multi-CAD interoperability and hybrid V4-V5 implementations.

– Deliver the power of PLM to communities of expert and casual users. CATIA Live Shape introduces a revolutionary direct 3D modeling paradigm. It allows casual users to quickly create design concepts in a lifelike environment and easily modify existing designs, including those from other CAD solutions. SIMULIA V6 DesignSight Structure makes advanced non linear finite element analysis technology available to non-experts.

– Provide advanced features for shipbuilding and energy, life sciences, industrial equipment, CPG, consumer goods, automotive, and aerospace, among other areas.

"PLM 2.0 is an enterprise-wide business transformation catalyst integrating both industrial business processes and dedicated applications. V6’s lifelike experience, IP collaboration, modeling, simulation and manufacturing solutions provide customers an agnostic and federating platform that truly accelerates PLM 2.0 transformations," says Dominique Florack, senior executive vice president, Products, Research and Development, Dassault Systemes. "V6R2010 delivers the promise of our virtual universes through our unified open architecture and our deep understanding of collaborative and social innovation needs."

DS portfolio consists of CATIA for designing the virtual product – SolidWorks for 3D mechanical design – DELMIA for virtual production – SIMULIA for virtual testing – ENOVIA for global collaborative lifecycle management, and 3DVIA for online 3D lifelike experiences. www.3ds.com/products/v6/v6r2010

Oracle Agile PLM enhances risk management, SOA architecture

Oracle’s Agile Product Lifecycle Management (PLM) 9.3 is a new enterprise PLM offering with advanced risk analysis, an enterprise PLM backbone that integrates other applications and hundreds of productivity-enhancing innovations. This latest release equips customers to drive profitable innovations, mitigate risk, lower development and product costs and improve productivity across the entire product lifecycle. It also represents the latest milestone for Oracle’s "Applications Unlimited" program, company says.

Enhancements and innovations in Agile PLM 9.3 include:

– Product Risk Management, Supplier Risk Analysis, Part Risk Analysis, Product Quality Risk Analysis, Product Design Volatility Analysis.

– Analytics enhancements with Agile PLM 9.2.2 and higher, such as Enterprise PLM Backbone allowing companies to integrate existing engineering and enterprise systems.

– SOA Enterprise PLM Platform with modularized web services, event management and extensible scripting for all PLM components including CAD objects to easily deploy, integrate, mash-up and extend product lifecycle processes.

– Integrated Product Master Data Management to manage data mappings, improve data quality and data governance across the heterogeneous systems integrated to the Enterprise PLM Backbone.

– Oracle Application Integration Architecture (AIA) – Continued development of out-of-the-box open standards-based integrations to broader enterprise systems including Oracle and SAP.

– User Productivity Tools, leveraging a Web 2.0 User Interface. Lab tests of Agile PLM 9.3 using real product data from a large global customer showed a 70 percent reduction in clicks and improvements to user productivity. New productivity improvements include:

– New User Interface Controls, personalization, simplified access, and training management.

video quick tours to reduce deployment time and training significantly.

– Hundreds of additional enhancements to processes across all modules including – Product Collaboration, Engineering Collaboration, Product Cost Management, Product Governance and Compliance, Product Quality and Project Portfolio Management.

"PLM has become a highly strategic tool that can impact profitability, mitigate risks and improve enterprise productivity," said Oracle vice president, PLM Product Strategy Hardeep Gulati. "With this latest release, Oracle extends its lead in delivering Enterprise-class PLM by giving organizations more out-of-the- box processes to support their corporate initiatives within the framework of a scalable, enterprise PLM backbone." www.oracle.com/plm

Siemens PLM Software launches Teamcenter 8, Tecnomatix 9

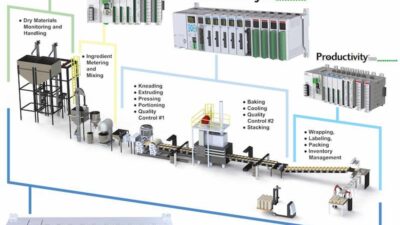

Siemens PLM Software, a business unit of the Siemens Industry Automation Division and a leading provider of product lifecycle management (PLM) software and services, today announced a set of new and enhanced software tools aimed at boosting productivity for the global manufacturing industry. Siemens PLM Software launched the latest versions of Teamcenter software, what it calls the world’s most widely used PLM system, and Tecnomatix software, its suite of digital manufacturing solutions.

"In today’s difficult global economic climate it is more important than ever for product producing companies to elevate and optimize their overall productivity," said Chuck Grindstaff, executive vice president of products and chief technology officer, Siemens PLM Software. "Our customers are evaluating every aspect of their business to look for new ways to improve productivity, from the shop floor to the executive suite." Grindstaff says the creative tools and features in the new versions of Teamcenter and Tecnomatix will help companies "reduce costs, increase revenue, and foster innovation."

Siemens says Teamcenter 8 delivers:

– Individual productivity by providing each user with an intuitive way to easily access product information and collaborate from anywhere in the world, inside the tools and processes they use every day without additional software or training.

– Application productivity with an expanding suite of end-to-end PLM applications targeting the product lifecycle, including new applications for Content and Document Management with advanced Microsoft Office 2007 integration, along with Formula, Package and Brand Management.

– New industry solutions for aerospace & defense, consumer packaged goods (CPG), and medical devices along with hundreds of updates in other areas.

– IT productivity with its unmatched scalability, open service-oriented architecture (SOA) and newly announced support for IBM’s DB2 Information Manager and several other IBM middleware products. Teamcenter provides a deployment strategy for every size organization, from small start ups to global enterprises, delivering a lower cost of PLM ownership. www.siemens.com/teamcenter

Tecnomatix 9:

– Improves planning productivity with integrated planning solutions that supply instant access to the latest product data while supporting capture, standardization and re-use of qualified manufacturing best practices.

– Offers tools to validate planning results and automate time-consuming planning tasks more efficiently. As a result, Tecnomatix can significantly improve manufacturing planning processes while enabling users to maintain the highest level of planning quality despite shorter development cycles.

– Drives manufacturing productivity in a variety of areas, including the optimization and commissioning of robots and automation equipment, manual workplace configuration to achieve output and safety objectives, efficient placement of factory equipment and material flow optimization.

"We are constantly trying to squeeze greater levels efficiency from our manufacturing planning process and Tecnomatix has played a key role in that effort," said Alexander Schmeh, managing director EBZ SysTec GmbH.

"Several of the new features being delivered in Tecnomatix 9 will go a long way to helping us meet our planning productivity improvement objectives." www.siemens.com/tecnomatix

Autodesk offers its history-free modeling technology, Inventor Fusion, on Autodesk Labs

The free Autodesk download is a technology preview and the first step in delivering technology that unites the power and control of parametric, history-based modeling with the speed and ease of use of direct, history-free modeling, Autodesk says.

Kevin Schneider, product manager of Emerging Products & Technology for the Autodesk Manufacturing Division, says Inventor Fusion provides seamless bidirectional parametric and direct workflows for users. The technology preview is the first step in delivering the full vision of Inventor Fusion to engineers everywhere, he says.

In addition, "Our manufacturing customers have told us that direct modeling is opening up new opportunities to accelerate product development. However, they’ve also told us that they don’t see the need for the power and control of history-based parametric modeling going away," says Robert "Buzz" Kross, senior vice president for the Manufacturing Industry Group at Autodesk. "We’re developing Inventor Fusion technology as part of a larger effort to combine the best of both disciplines to further improve the product design process."

Get the download, see videos of the technology, and learn more about Autodesk Inventor Fusion .

– Edited by Mark T. Hoske, electronic products editor, MBT www.mbtmag.com