Adopting new technology such as virtual reality (VR) and augmented reality (AR) will help train younger employees faster without comprising safety on the plant floor.

Smarter learning, training, and working needs to be embraced with immersive technologies such as virtual reality (VR) and augmented reality (AR) to better prepare the younger manufacturing workforce as older generations leave and retire.

The process industries cannot dodge the demographic earthquake they are experiencing. They will not be able to hold onto the generation of baby boomers nearing retirement for long. The youngest of this generation is already in their mid fifties; the oldest are over 70 and expected to retire soon. The rapidly aging manufacturing workforce presents related challenges. The first is capturing and retaining the knowledge of experienced workers before they leave or retire. Without the necessary training, businesses risk losing many advances in efficiency, reliability and safety these employees delivered during their decades in the industry.

Another challenge is effectively passing knowledge and skills on to the younger workforce and restructuring workplaces to get the best from millennials aged 22 to 37. Research indicates millennials follow a different approach to learning and working compared to baby boomers.

This shift is also happening very quickly. Millennials are the largest generation in the workforce, and they are rapidly taking their places across organizations as baby boomers leave. A decade ago, World Petroleum Council director generalPierce Riemer said the industry was on “the edge of a demographic cliff.” We are now halfway down. Businesses need to ensure a soft landing.

Training a younger workforce

To make this transition a success, businesses need to meet the needs and adapt to the characteristics of younger workers. Much of the media has focused on the “challenge” millennials present. This is self-defeating and unjustified. The demographic shift in workplaces and younger workers’ affinity for technological solutions and collaborative working opens opportunities for faster, smarter working and learning. The march of the millennials is an opportunity successful businesses will grasp.

First, younger employees have a natural preference for experiential learning instead of traditional, lecture-based training. This should push operators to look to practical, hands-on learning experiences to supplement and, in cases, replace classroom sessions.

In this respect, the preferences of millennials are, an accurate reflection of what works. According to the NTL Institute for Applied Behavioral Science, the “learning pyramid” shows hands-on learning is at least eight times more effective than lectures in promoting knowledge retention. Meeting demands for increased experiential learning will enhance teaching effectiveness.

How can plants provide hands-on experience without risking the safety or operational efficiency of the plant? Untrained staff, after all, cannot be left unmonitored in a plant facility.

To meet the needs of a younger workforce, businesses can significantly enhance operations by accelerating learning and boosting productivity through VR and AR training.

Training with VR and AR

The first vital characteristic millennials bring is an affinity for technology. They are the first generation of “digital natives,” born and raised in an environment saturated by “computers, video games, digital music players, video cameras, cell phones, and all the other toys and tools of the digital age.

This knowledge reduces the barriers to adopt technologies and bridges the gap between the requirements for hands-on training to develop key skills and the need to protect facility operations and safety. Immersive technologies such as virtual reality (VR) and augmented reality (AR) are key solutions. Younger employees readily adopt both of these technologies.

Whether in a fully realized virtual environment or “mixed reality” with graphics superimposed on the real world, the technologies give users hands-on practice for key tasks that will be required to do the job properly.They can practice working on realistic, 3-D cabinets or meters, with a minimized risk to the process or worker safety.

AR and VR technology can significantly enhance skills and help trainees retain up to 100% more information compared to traditional, lecture-based learning. That, in turn, reduces the length of technical training by up to 66%. In a typical plant scenario, it can slash competency times from 6 months to 2 months.

Immersive learning is not just more effective; it is also more flexible and efficient. Deployed through the cloud, businesses can connect staff with trainers across the world and avoid the need to bring employees to a central training location, reducing travel costs and saving time. Linked to this, lesson modules can be rapidly deployed. If engineers encounter a problem with unfamiliar equipment, they can practice an operation in an AR or VR environment in the morning and complete the task in the afternoon.

The model opens the door to just-in-time training-learning on demand to meet employees’ needs and operational demands as they arise.

Because millennials are used to having information on demand, they may spend less time preparing for a task before beginning, enhancing knowledge as they proceed, as needed.

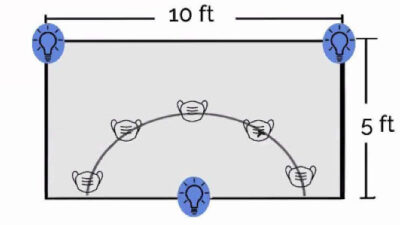

There is evidence the new generation is highly collaborative and are willing to work together, often online, regardless of an existing relationship. Millennials are noted as the “collaboration generation.” Again, this opens the door to new approaches to learning and development that can significantly enhance operations-for example, intelligent wearables (Figure 1) with voice control. Again, it takes familiar technology for younger workers and applies it to an industrial setting.

The technology addresses the need for on-demand information and collaboration. Intelligent wearables provide real-time information on devices and the process as well as live video and communications to allow users to communicate with the central control room or remote experts, who can connect and see what the worker sees.

Workflow management software provides users with support and guidance and contextual information by connecting to tools plant facilities already use, such as software for enterprise resources planning, maintenance management, or sales management.

The software captures the existing workforces’ skills and expertise and delivers it effectively to new employees in other mobile technologies such as tablets and smartphones. A growing library of video clips of common maintenance tasks ensures knowledge isn’t lost and is available on-demand. Software also gives users and third parties the ability to design their own applications and harness new technologies such as artificial intelligence to develop new applications.

Immersive and wearable technologies deliver faster, more flexible strategies for learning. Both technologies break down the distinction between learning and working, and between productivity and training tools.

There is also significant evidence younger employees are staying in their roles for shorter periods of time. Close to half in some surveys say they intend to leave their current employer in less than 2 years.

Whether this is a generational divide or just a reflection of changes that need to be made to accommodate the younger workforce, a majority of workers are not staying with their current employer for nearly as long as before.

Immersive technologies and intelligent wearables enable workers to quickly train younger workers without compromising safety. AR and VR are proven to be more effective than classroom-based lectures to instill the knowledge and behavior that constitute competency on the plant floor. Times to competency are estimated to be reduced by as much as two-thirds with AR and VR. At the same time, intelligent wearables meet the need and desire of a new generation of employees to access information “on-the-fly”and getting to work with the basic knowledge and competencies required. The new technologies enable businesses to boost productivity and gain value from the new generation, despite retention challenges. It is imperative to adopt a new approach to learning that is faster, more flexible, and more targeted, getting the right skills at the right time to the right people. Whether organizations call it training or productivity matters less than what it helps businesses achieve: Getting the job done right.

Youssef Mestari, program director at Honeywell Connected Plant. Edited by Emily Guenther, associate content manager, Control Engineering, CFE Media, [email protected].

MORE ANSWERS

KEYWORDS: Virtual reality (VR), augmented reality (AR)

Exploring how younger generations can train with immersive technologies

Developing industry knowledge and skills for new employees

Consider this: Does your facility have a proper training program in place for career development?

ONLINE

Read more about career development and industrial training online at www.controleng.com.

Receive on-demand training with CFE Edu at https://cfeedu.cfemedia.com.