The Industrial Internet of Things (IIoT) and artificial intelligence (AI) are two key technologies that are making smart manufacturing a reality and driving significant bottom-line benefits for manufacturing operations.

Smart manufacturing insights

- Tools like the Industrial Internet of Things (IIoT) and artificial intelligence (AI) are changing the ways in which manufacturers operate.

- AI can be used to enhance data collection and analysis.

- AI agents and copilots are the latest in AI technology.

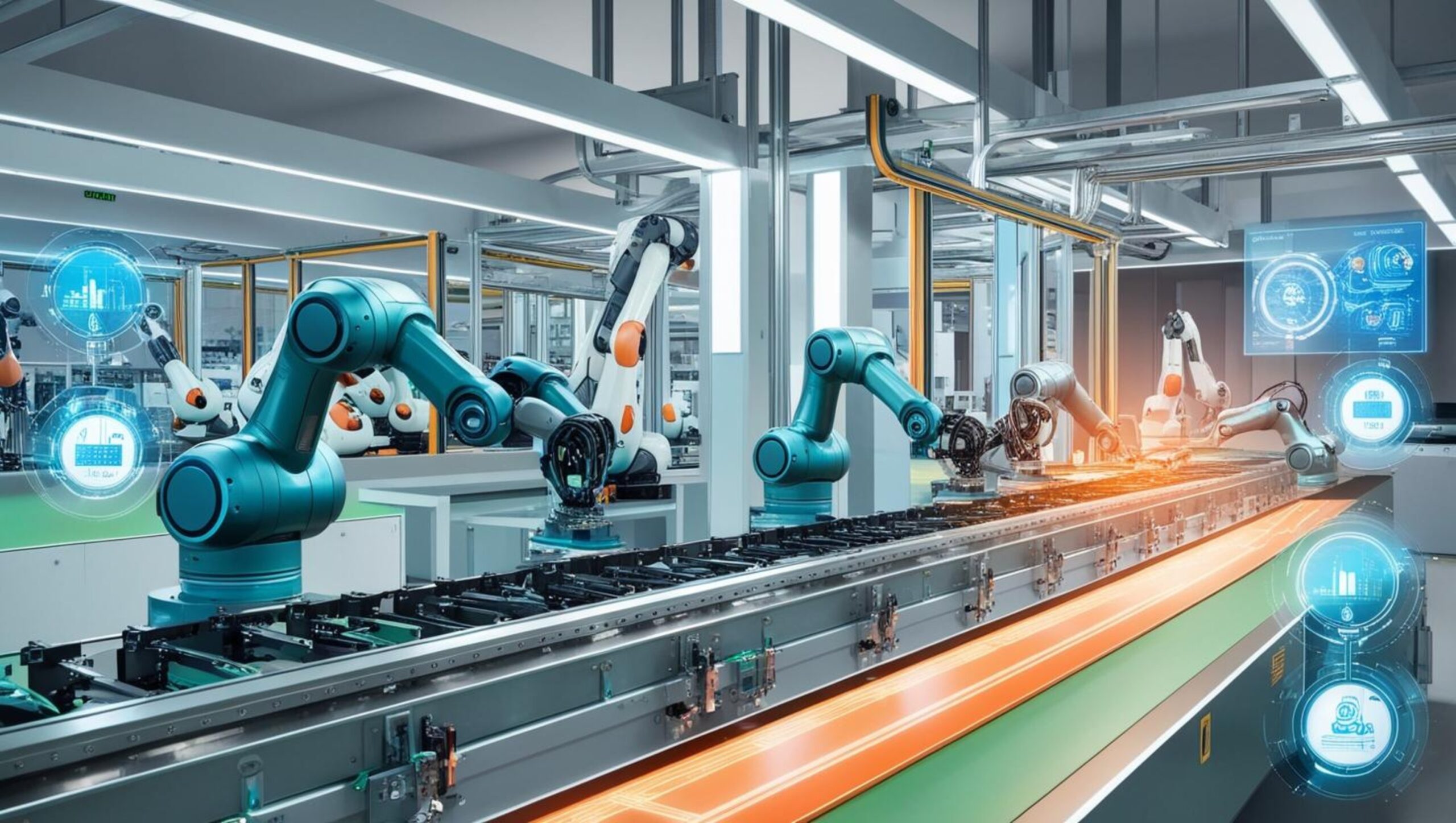

Smart manufacturing is transforming the industry back into an economic powerhouse. It’s helping manufacturers increase productivity, reduce costs and deliver exciting new products and capabilities to customers.

Smart manufacturing is the intelligent real-time orchestration and optimization of business, physical and digital processes within factories and across the entire supply chain. Smart people are using smart technology to improve manufacturing operations.

A wide mix of new and not-so-new technology is fueling the success of smart manufacturing. Robots, collaborative robots (cobots), advanced identification technologies, cloud technology, 3D printing, manufacturing execution systems (MES), augmented reality, virtual reality, digital twins, digital threads and many more contribute to the success.

Two technologies worth mentioning in more detail are the Industrial Internet of Things (IIoT) and artificial intelligence (AI). These two technologies come in many flavors, but both are becoming ubiquitous in manufacturing operations and are having a significant impact on the bottom line.

IIoT’s and AI’s roles in smart manufacturing

The IIoT has become almost synonymous with smart manufacturing. It serves as the foundation for many global smart manufacturing initiatives and innovations.

The IIoT collects data from virtually every data source in a plant and makes that information available in real time to the people who need it. More importantly, the IIoT adds context to this data so the data is clearly understood and visible across the enterprise.

Every key aspect of manufacturing operations relies on data. Understanding what’s happening, why it’s happening, what will happen next and what actions must be taken is all data-based. The IIoT delivers this information in real time, making sure the right people have access to the data when they need it. In the manufacturing sector, success depends on the data, and the IIoT is critical to delivering it.

AI plays a crucial role in managing data with the IIoT. In many manufacturing operations, once the IIoT is fully implemented and operational, the amount of data can be overwhelming. It becomes challenging for people to identify which data is critical and which requires immediate attention for decision making.

Using AI to analyze data

AI is good at analyzing the vast amount of data that manufacturing operations generate to understand what’s happening and why. The amount of data doesn’t matter; AI can analyze the data and quickly identify the root causes of current issues.

And more than that, AI can translate its analyses into natural language, making it easily understandable and actionable. It also provides easy-to-understand recommendations that can be put into action quickly.

The bottom line is the IIoT relies on AI to analyze the vast amounts of data it collects and translate the results into actionable recommendations. But AI needs the IIoT as well, because without the data collected by the IIoT, AI isn’t as effective. Manufacturing is all about the data. When the IIoT and AI work together to collect and analyze data, the impact to the bottom line is significant.

How manufacturers are using AI agents and copilots

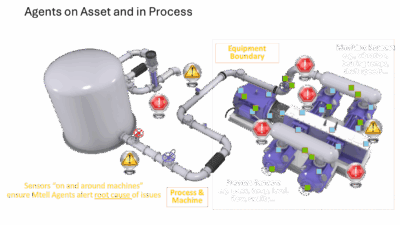

AI agents and copilots are the latest AI tools manufacturers are using. AI agents are standalone autonomous AI applications which perform their tasks without any collaboration from operators. AI copilots are collaborative AI applications that operators use interactively to perform their tasks.

Here are some uses of AI agents and copilots in manufacturing:

Predictive maintenance

With the IIoT, AI agents collect and analyze information about the manufacturing equipment operation. The AI agent constantly analyzes all aspects of the data in real time, looking for potential anomalies before they occur.

AI agents must be trained on existing data to recognize specific patterns, but they can also use open training to identify new or previously undetected patterns. This approach enables the AI agent to predict potential problems before they occur, allowing personnel to perform equipment maintenance when needed. This process minimizes both downtime and maintenance costs. With the integration of the IIoT and AI agents, these processes occur in the background, and operators are only alerted when anomalies are detected.

Business systems

Most business systems like enterprise resource planning (ERP) systems require a significant amount of manufacturing data. Business systems usually require data, such as production, consumption, orders, status, quality results and non-conformances from the shop floor.

AI agents, again with the IIoT, collect the data from various shop floor sources. They organize this data according to the business system requirements and deliver it to those systems when needed. With the IIoT and AI agents working in the background, this process involves minimal operator effort.

Quality inspections

Quality tests and inspections can be complex in that different product variations require different tests and inspections. Ambiguous results or test failures might require different paths forward, such as retesting, additional testing, non-conformances, downgrades and rework.

Quality assurance (QA) and quality control (QC) operators use AI copilots to navigate the complexities of various quality tests and inspections. These AI copilots make sure the correct tests are performed, necessary retests are performed, correct actions are taken and proper dispositions are made. The QA/QC operators collaborate closely with the AI copilots, who guide them through each step of the process based on the test results and the requirements for the next steps.

AI computer vision systems are a great example of AI-based solutions being used to improve quality inspections. AI vision systems leverage AI tools to extract meaningful data from images, enabling quality inspection applications to detect and categorize anomalies at high speeds and high levels of accuracy. Feedback from the AI vision systems supports both open- and closed-loop adjustments to the manufacturing equipment in real time, all significantly increasing the first-pass quality output of the manufacturing process.

Error proofing

Manufacturing processes are getting more complex, and product variations often introduce subtle differences in the processes. Even simple operator errors can impact the final quality of the product to the point where it can’t be sold or must be reworked before it’s saleable, which costs time and money.

Operators use AI copilots to errorproof their processes and minimize errors in the processes. AI copilots will typically ingest the work instructions, operating manuals and other documents relevant to the manufacturing processes. Next, instead of the operators trying to perform the processes from memory or use these large, complicated and often cumbersome manuals, the operators simply work collaboratively with the AI copilots to execute the manufacturing processes. The AI copilots help the operators follow the steps in the manuals and work instructions correctly and completely.

How generative AI is reshaping manufacturing

Generative AI (GenAI) is another aspect of AI that’s starting to have a huge impact on manufacturing operations. GenAI is AI that processes large amounts of information and generates new content based on that information. This new content can take many forms, leading to numerous applications for GenAI in manufacturing. Here are just a couple of examples:

Training

For manufacturing operations, training is essential and often needed on a continual basis. This necessity is not only from new personnel joining the team but also from the need to cross-train people in various aspects of the operation. Additionally, operations constantly change and evolve as new technologies and techniques are introduced.

GenAI can process large amounts of documents related to operations, equipment, processes, procedures, manuals and work instructions. Using this information, it can develop comprehensive training materials. These materials include not only traditional training documents but also complete training regimens, which include classroom materials, online resources, refresher courses, interactive content and testing materials. GenAI can create all these elements, confirming that the training curriculum is accurate, comprehensive and up to date with the latest operating procedures.

But more than that, GenAI can generate tailored training materials, customized to individual needs and experiences. Leveraging historical data, GenAI can create personalized training scenarios for diverse learners. GenAI also identifies specific knowledge gaps and develops personalized training content to bridge them. Additionally, it identifies further training needs by analyzing patterns, such as frequently accessed information, recurring questions and testing and evaluation results, again all based on individual learning needs.

Shift handover

Many manufacturing operations run 24/7 or 24/5 with three shifts per day. This means transitioning from one shift to another must be done quickly, typically within 10 to 20 minutes. For an efficient handover, significant effort is often put into collecting data from the shift, filtering and sorting that data to identify what is most relevant and then generating the required reports, charts or other necessary documentation.

GenAI makes this process so much easier. GenAI takes the data collected during the shift from the IIoT and uses it to generate the required reports and charts. GenAI sorts the relevant information from the irrelevant, highlighting only what is needed for the next shift to address open issues and keep operations running smoothly.

Control system code generation

Most manufacturing operations have significant levels of automation and controls, which means significant levels of automation and control systems code. GenAI significantly helps controls engineers generate and manage their code, as well as summarize the code and troubleshoot when problems arise. GenAI helps generate new code, when changes need to be made or when new processes or equipment are added. GenAI also helps modernize and optimize the code, all making the control engineer much more efficient and effective.

Smart manufacturing aims to boost productivity and cut costs

Smart manufacturing is enabling manufacturers to increase productivity, reduce costs and introduce new products and capabilities. The IIoT and AI are two key technologies that are making smart manufacturing a reality and driving significant bottom-line benefits for manufacturing operations.

The IIoT supports smart manufacturing across various sectors, while AI helps analyze the data and deliver relevant insights to operators. AI agents perform tasks in the background, making sure everything gets done with minimal human involvement. Additionally, AI copilots work interactively with operators to make sure that operators perform the most difficult tasks completely and correctly. GenAI is also creating content in manufacturing, providing essential information to the right people at the right time.

Whether it’s the IIoT, the collaboration between the IIoT and AI, AI agents, AI copilots or GenAI, these technologies have a huge impact in manufacturing. The IIoT and AI are becoming ubiquitous throughout the industry, delivering tangible benefits to manufacturing companies. Expect to see many more applications of the IIoT, AI agents, AI copilots and GenAI as these tools support smart manufacturing and help transform the manufacturing sector back into an economic powerhouse.

John Clemons is a solutions consultant for LifecycleIQ Services at Rockwell Automation. Edited by Sheri Kasprzak, managing editor, WTWH Media, [email protected].