How deterministic Ethernet with TSN empowers HMI/SCADA integration, unifies IT and OT networks, and drives real-time performance in smart manufacturing environments.

Time-sensitive networking insights

- Time-sensitive networking (TSN), through Institute of Electrical and Electronics Engineers (IEEE) 802.1AS and 802.1Qbv standards, enables precise synchronization and scheduled traffic, allowing Ethernet to support time-critical applications like motion control and safety systems.

- TSN allows diverse data types — including HMI/SCADA, control signals and IT traffic — to coexist on a single network, streamlining architectures, lowering costs, improving uptime and enhancing data transparency.

- By enabling seamless communication between factory-floor devices and enterprise systems, TSN is a foundational technology for IIoT and digital transformation, supporting advanced use cases like predictive maintenance and process optimization.

In the rapidly evolving landscape of industrial engineering, time-sensitive networking (TSN) emerges as a transformative technology poised to redefine industrial communications and factory automation. Based on the IEEE 802.1 standards, TSN enhances traditional Ethernet by introducing deterministic capabilities that ensure precise, reliable and predictable data transfer.

For engineers tasked with designing futureproof digital manufacturing systems, TSN offers a compelling solution to meet the demands of Industry 4.0 and beyond. Technology exists today in the form of gigabit Ethernet switches, controllers and devices to implement all new TSN-based architectures.

TSN: A technical overview

TSN operates at Layer 2 (data link layer) of the open system interconnection (OSI) model, augmenting Ethernet with deterministic features that traditional Ethernet lacks. Unlike conventional Ethernet, which prioritizes flexibility and scalability over timing precision, TSN guarantees low-latency, jitter-free communication — a critical requirement for real-time industrial applications such as motion control, robotics and safety systems.

The deterministic nature of TSN hinges on two new (introduced in 2016) IEEE sub-standards: IEEE 802.1AS (“Timing and Synchronization for Time-Sensitive Applications”) and IEEE 802.1Qbv (“Enhancements for Scheduled Traffic”). These standards work in tandem to synchronize network devices and prioritize time-critical data, laying the groundwork for robust, high-performance industrial networks.

IEEE 802.1AS: Precision synchronization

The IEEE 802.1AS standard, an evolution of the IEEE 1588 Precision Time Protocol (PTP), enables microsecond-level synchronization across all devices in a TSN network.

This level of precision eliminates the time drift (or jitter) common in standard Ethernet networks, in which devices rely on independent internal clocks. In traditional setups, cumulative timing discrepancies can disrupt data transfer, leading to delays or packet loss — unacceptable outcomes in time-sensitive applications like closed-loop control systems. By contrast, IEEE 802.1AS ensures that all network elements operate in lockstep, providing a stable foundation for deterministic communication.

IEEE 802.1Qbv: Scheduled traffic management

Building on the synchronized environment established by IEEE 802.1AS, the IEEE 802.1Qbv standard introduces traffic scheduling through time-aware shapers (TASs) embedded in network switches. TASs leverage time division multiple access (TDMA) principles to allocate periodic time slots for transmitting critical data, such as motion control commands or safety signals. During these reserved windows, only high-priority traffic is permitted, effectively isolating it from non-critical data streams like video feeds or diagnostic logs.

This prioritization mechanism ensures that time-sensitive packets are delivered with minimal latency and zero interference from lower-priority traffic. Since all network devices and TASs are synchronized via IEEE 802.1AS, each node knows precisely when to send or expect priority data. Engineers can define these schedules within the traffic profiles of data packets, optimizing network performance for specific use cases. This deterministic approach contrasts sharply with traditional Ethernet’s best-effort delivery model, making TSN ideal for applications requiring guaranteed bandwidth and timing.

A new standard is enabling data convergence and network efficiency

TSN’s determinism not only prevents network congestion and data loss but also facilitates the convergence of diverse traffic types onto a single-network infrastructure. For example, engineers can integrate HMI/SCADA with input/output (I/O) data, motion control signals and safety communications without compromising performance. Beyond these core industrial flows, TSN supports additional Ethernet traffic — such as from cameras, barcode scanners or printers — alongside other protocols, all coexisting seamlessly.

From a systems engineering perspective, this convergence translates to significant cost savings. By reducing the need for separate networks, TSN lowers capital expenditure (CAPEX) and simplifies network architectures. A streamlined topology enhances bandwidth utilization and reduces points of failure, enabling faster troubleshooting and minimizing downtime. Moreover, TSN’s flexibility allows engineers to reconfigure networks dynamically — adding or removing devices and adapting to evolving operational requirements — without disrupting performance.

Bridging IT and OT for data-driven manufacturing

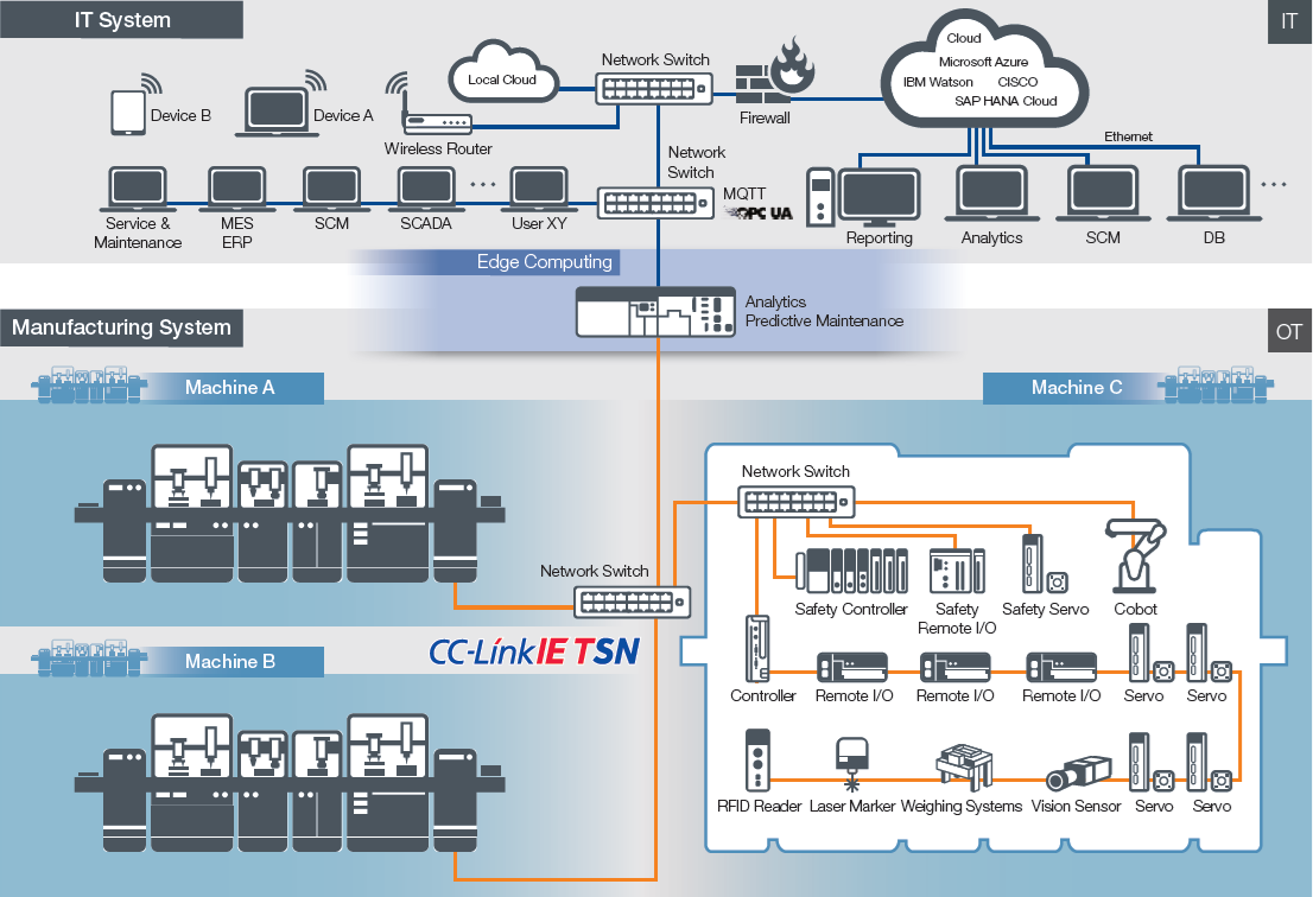

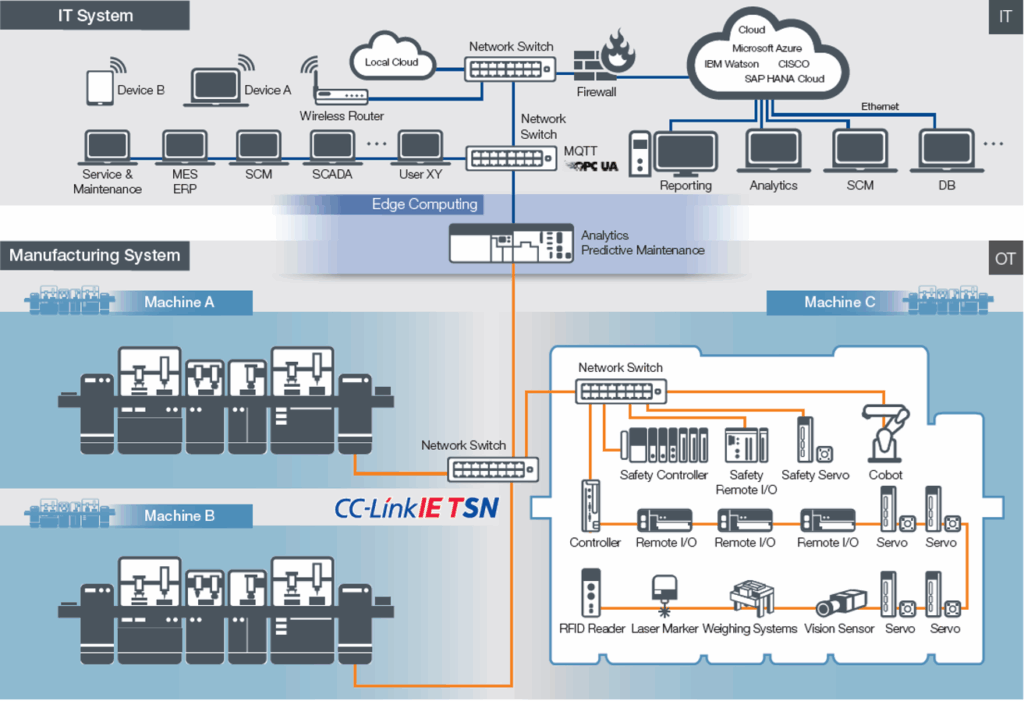

The true power of TSN lies in its ability to unify information technology (IT) and operational technology (OT), a critical enabler of data-driven manufacturing. By converging IT and OT traffic, TSN provides unprecedented transparency into industrial processes. Engineers can extract real-time data from factory floor devices, feed it into predictive analytics models, and derive actionable insights to optimize performance, efficiency, and product quality.

For instance, TSN enables the seamless integration of sensor data with enterprise-level systems, supporting advanced applications like predictive maintenance and process optimization. This IT-OT fusion is a cornerstone of the industrial internet of things (IIoT), particularly in North America, a region that has emerged as a global leader in IIoT adoption. To maintain competitiveness in this innovation hub, engineering teams must leverage TSN to unlock the full potential of IIoT frameworks.

How Ethernet with TSN benefits manufacturing

Key to communications management is a converged, high-bandwidth network infrastructure to support digital transformation strategies. Convergence allows everything to communicate on the same network architecture, avoiding multiple networks’ cost and complexity. It’s the foundation of high-speed, real-time deterministic communications between disparate devices and systems, sharing data across the entire enterprise, regardless of source or destination. This provides the transparency required for fully optimized operations by allowing the data to flow from its source to be processed for actionable insights, then fed back. This does not just apply to supervisory systems. Having real-time control and coordination of multiple different shop floor or operational technology (OT) systems is also critical.

Ethernet with TSN and gigabit bandwidth delivers a series of benefits to manufacturing in general, such as:

- Reduces costs, shortens project timelines and increases uptime by simplifying network architectures and hence system designs.

- Convergence avoids multiple network types to handle different process traffic.

- Delivers greater process transparency and optimized operations. Converged network architectures allow data to flow where it’s needed. This is the key to managing processes in the best way.

- Delivers greater productivity, as optimized processes will run in the most productive way. Offers better integration of OT and information technology (IT) systems, as a converged stream of data can be shared between the factory floor and supervisory systems more easily.

What industries use Ethernet with TSN?

Today, more than 100 leading global manufacturers are reaping the benefits of Ethernet with TSN in their operations worldwide. These cover industries as diverse as automotive, consumer electronics, consumer packaged goods, food and beverage, lithium batteries, logistics, semiconductors and many more.

The leading industrial network leveraging gigabit Ethernet with TSN is CC-Link IE TSN, managed by the CC-Link Partner Association (CLPA).

CLPA was established in 2000 to develop and promote the CC-Link family of open industrial automation network technologies. Since then, they have grown into a global organization with a track record of innovation. In a series of firsts, the CLPA introduced open industrial Ethernet technology with gigabit bandwidth in 2007. Building on this success, they were the first to combine gigabit bandwidth with time-sensitive networking in 2018.

Today, the leading CLPA offering is CC-Link IE TSN, the world’s first, and so far only, open industrial Ethernet technology that combines gigabit bandwidth with time-sensitive networking.

This provides manufacturers an excellent choice for machine builders looking to save cost, improve efficiency and improve connectivity between the OT and IT worlds.