PID loops control a majority of the automated processes in industrial facilities. The proportional-integral-derivative (PID) algorithm is both simple and reliable, and has been applied to hundreds of thousands of control loops over the last 50 years.However, not all industrial processes can be controlled with PID loops.

PID loops control a majority of the automated processes in industrial facilities. The proportional-integral-derivative (PID) algorithm is simple, reliable and has been applied to hundreds of thousands of control loops over the last 50 years.

But not all industrial processes can be controlled with PID loops. Multivariable, nonlinear, and random processes, for example, all require more advanced control techniques. There was a time such technology was available only in academic laboratories and in the aerospace industry, but the advent of affordable computing platforms has made even the most arcane algorithms accessible to industrial users.

Model predictive control

One of the first advanced control techniques to be commercialized was model-predictive control , which accounts for process interactions, overcomes disturbances, and predicts future performance using a process model. The first software package based on model-predictive control technology was the IDentification and COMmand controller (IDCOM) developed by Adersa.

Adersa now offers a second generation model-predictive control package known as Predictive Functional Control (PFC). PFC is designed to keep a process variable constrained within a specified range around the setpoint. It uses the process model to determine the present control efforts required to keep future values of the process variable within the prescribed range.

According to Adersa’s director, Dr. Jacques Richalet, “PFC is intended for classical PID users. It addresses the field of difficult processes (time varying, nonlinear, unstable, inverse response, split range, etc.), as well as slow processes like chemical reactors, and fast processes like rolling mills and mechanical servo mechanisms where the PID algorithm is not efficient enough.”

Dynamic matrix control (DMC) is another example of advanced control technology transferred from academia to industry. Charlie Cutler, a pioneer in multivariable control techniques, took the results of his Ph.D. research and created his own model-predictive controller based on DMC technology. The latest version of DMC, known as DMCPlus, is now available from Aspen Technology, where Dr. Cutler serves as senior adviser.

More model-based techniques

At ControlSoft, model-based control technology has taken the form of the Modular Multivariable Controller (MMC). MMC incorporates a technique called internal model-based control (IMC) that uses the process model not as a means of predicting the future behavior of the process, but as a means of counter-acting undesirable process dynamics. ControlSoft was founded by a group of alumni and faculty that contributed to the development of IMC technology at Case Western Reserve University.

Of course, not all the latest control techniques have been developed in academia. David Cawlfield, software developer at Olin Chemical’s Chlor-Alkali division, developed a model-predictive control algorithm for regulating Olin’s chemical and petrochemical processes. The results are now available commercially as the Olin Modular Network and Control System (OMNX) from OMNX Open Control. Mr. Cawlfield characterizes OMNX as a “drop-in self-tuning replacement for PID.”

The independent thinking that went into the development of OMNX has lead to several distinguishing features. Most notably, the software is highly efficient at calculating the required control efforts. According to Mr. Cawlfield, OMNX runs at a speed several orders of magnitudes faster than traditional model-based control techniques.

Fisher-Rosemount and Honeywell Industrial Automation & Control have also developed model-based control packages in-house, each with distinguishing features. Fisher-Rosemount’s Variable Horizon Predictive controller incorporates model-predictive control technology in a way that looks and feels much more like familiar PID control. Honeywell’s Robust Model-Predictive Control Technology is designed to be particularly “robust” or immune to model uncertainty.

Robustness is also the goal of Fisher-Rosemount’s new multivariable predictive control software called MVP Control, scheduled for release early this year. According to Laurie Ben, advanced control solutions program manager at Fisher-Rosemount, the MVP Control software will incorporate methodologies for developing and tuning a controller to make it less sensitive to discrepancies between the model and the actual behavior of the process.

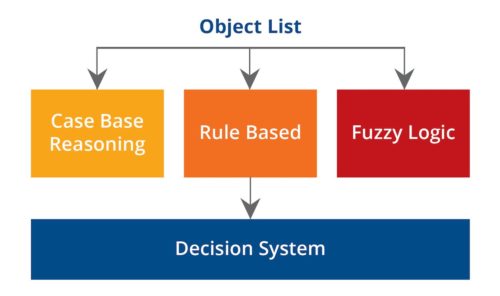

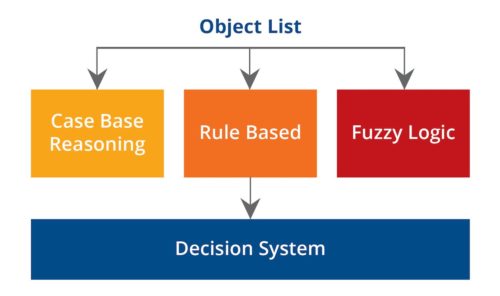

Fuzzy logic, gain scheduling

In spite of their popularity, model-based controllers can’t solve all of the world’s advanced control problems. Processes that are poorly understood and processes that demonstrate variable behavior are particularly difficult to model.

Fisher-Rosemount offers several alternatives. Their Intelligent Gain Scheduler combines fuzzy logic with traditional gain scheduling . Gain scheduling allows a controller to update its tuning parameters as the operating conditions change. This technique is typically applied to a process with variable gain; i.e., a process that becomes more or less sensitive to control efforts as the setpoint changes. To maintain a constant sensitivity overall, a gain scheduler will automatically decrease or increase its own gain to compensate for a change in the process gain.

A traditional gain scheduler works best when the process gain is known to vary with the setpoint in a precise manner. For processes that are not so well understood, the Intelligent Gain Scheduler can use fuzzy logic to tweak the controller gain by “a little bit” or “a lot” rather than by precise increments. It is designed to overcome nonlinearities in both the static and dynamic elements of a control loop and to improve loop performance despite process variations.

The Exact MV controller from The Foxboro Co. also uses an advanced form of gain scheduling. Its parameters are constantly updated by an “adapter” that tracks changes in the behavior of the process. Separate gain scheduling is saved for upswings and downswings in the controlled variable. Fuzzy logic is used as a backup when the primary adaptation method fails.

More fuzzy logic

Fisher-Rosemount has also incorporated fuzzy logic into their Intelligent Fuzzy Logic Controller. This software allows users to apply fuzzy logic to existing control loops. Its purpose is to achieve a faster and tighter process response than a conventional PID controller can achieve alone. According to Fisher-Rosemount’s Ms. Ben, users are finding fuzzy controls particularly helpful for temperature control applications.

Inform Software Corp. has applied fuzzy logic to PLC and DCS-based control using its fuzzy Tech development software. In cooperation with Klöckner-Moeller, Inform has developed the “fuzzyPLC” that integrates conventional control techniques with fuzzy logic. A software-only version is available for several PLC and DCS platforms. It allows users to monitor fuzzy logic systems in real time and to modify the control strategy on the fly.

According to Inform’s director of fuzzy technology, Constantin von Altrock, “Fuzzy logic enables developers to implement supervisory control strategies directly from a human operator’s experience and experimental results. In many applications, this shortens the design time to only a fraction.” For applications in which no operator experience is available, Inform provides a NeuroFuzzy add-on module that automatically generates fuzzy logic control rules from sampled data.

Neural networks help with process behavior

Sometimes the challenge of controlling a difficult loop is more a matter of uncertain process data than uncertain process behavior. Neural networks can help in these situations by inferring the current value of the process variable from a collection of related variables. Using historical data, a neural network can be “trained” to “learn” the often complex relationships among the measurable variables and the variable of interest. Once these relationships are known, the current value of the inferred variable can be calculated from the current values of the variables that are actually measured.

Fisher-Rosemount offers an Intelligent Sensor Toolkit for creating such virtual sensors. Ms. Ben notes that the Toolkit is finding other uses as well. “Customers are also using it for process analysis and knowledge discovery to help determine pieces of their process model in a variety of control applications.”

This analysis often amounts to identifying the cause-and-effect relationships between the inputs and outputs of a process. Neural networks are particularly helpful for analyzing processes that can not be quantified by traditional linear models. NeuCOP II from NeuralWare combines neural networks, statistics, and multivariable modeling techniques to create dynamic, nonlinear models from process data.

A controller that can compute optimal actions without violating constraints

NeuCOP II controller incorporates these nonlinear models into a model-predictive control strategy with an embedded optimizer. It can compute optimal control actions without violating the operating constraints. The results can then be displayed to an operator for manual implementation or fed to a real-time control system, such as DMCPlus, for automatic implementation. “This combination of neural nets with our existing control technologies creates a powerful solution,” says Larry Evans, chairman and ceo of AspenTech. “For example, neural networks can be installed in existing multivariable control applications to improve our ability to calculate inferential properties and to provide tighter control of highly nonlinear processes.”

The Process Perfector from Pavilion Technologies also combines neural networks with model-predictive control technology. Unlike traditional model-predictive controllers, however, Process Perfector uses a nonlinear model that is applicable to a wider range of processes. The neural network is used to invert the model so that control efforts required to produce a future process response can be identified. Developer Greg Martin claims that the neural network allows this inversion operation to be completed much faster than by traditional means. As a result, Process Perfector can be applied to processes that were previously considered to be too fast to control with traditional model-based techniques.

The benefits of adaptive control

Many of the advanced control techniques that employ fuzzy-logic and neural-network technology are designed to accommodate variations in the behavior of the process. Such controllers are said to be adaptive since they can modify their own control strategies to adapt to the new process behavior.

One of the first adaptive controllers available for commercial use was Foxboro’s Exact. The multivariable version, Exact MV, features on-line adaptive capabilities for both the feedforward and feedback components of a control problem. Exact MV controller can handle up to four feedforward inputs, allowing it to function effectively as a multi-loop decoupler. The controller can also function as a Smith Predictor, with a deadtime estimate that is continuously updated. “This makes it particularly useful on difficult to control dead-time-dominant and dead-time-variable processes, ” according to Tom Kinney, Foxboro’s director of systems technology.

ControlSoft offers an adaptive PID control package called InTune. It continuously monitors a loop’s performance and updates the P, I, and D tuning parameters to improve the closed-loop response. It works like an expert control engineer by tweaking the tuning parameters according to a complex set of empirical rules.

BrainWave from Universal Dynamics Technologies combines adaptive control technology with model predictive control. It employs a dynamic modeling technique to automatically build mathematical models of the process and to adapt them on-line while continuing to control the process. Using the most recent models, BrainWave can predict the effect of control changes and feedforward disturbances so as to reach the setpoint smoothly and rapidly without oscillation. By constantly updating its process models, BrainWave attempts to account for unexpected or time-varying process behavior.

“BrainWave has demonstrated 30% to 50% reduction in deviation from set point compared to the PID controls that were replaced in plant applications. It realizes substantially improved control in applications with a deadtime/time-constant ratio greater than one, which cannot effectively be handled with PID control,” says Bill Gough, product manager. Mr. Gough also notes that BrainWave, like Foxboro’s Exact MV, is most effective in applications with long or varying deadtimes and time constants.

A bit of everything

Connoisseur from Predictive Control Ltd. goes even further to combine the best of several advanced control techniques. Like BrainWave, it employs a model-predictive controller that can be adapted on-line to current process conditions. Connoisseur also uses neural networks to compensate for nonlinear processes and fuzzy logic to adapt the control problem when traditional science doesn’t yield the desired results.

Connoisseur has its own distinguishing features too. Its multimodeling capability is designed to apply to both continuous and batch processes. It also uses a nontraditional control structure for model-predictive control. According to Foxboro’s Mr. Kinney, “This technique provides dramatic improvement in real-world situations where the controller is subjected to unmeasured load disturbances.”

Just how well these advanced control strategies will be accepted in a PID-centric industry and what elaborate control software will be available in the future is anybody’s guess. One thing is certain — with inexpensive computing power available at all levels of the controls hierarchy, PID loops won’t be alone for long.

This article originally appeared Jan. 1, 1998.