Encompassing a number of techniques that address specific loop problems and fundamental design techniques, advanced regulatory control can be applied to deal with variable gains, variable operating conditions, external disturbances, and control loop interaction. Many factors can degrade the performance of single-loop controls.

Sidebars: Feedforward equations

Encompassing a number of techniques that address specific loop problems and fundamental design techniques, advanced regulatory control can be applied to deal with variable gains, variable operating conditions, external disturbances, and control loop interaction.Many factors can degrade the performance of single-loop controls. In general, these factors fall into two groups: (1) changes in process characteristics and (2) changes in operating conditions. Both can have similar effects and be compensated for in similar ways.

Gain: the key concept

The key concept is gain, the ratio of an output change to an input change. Control loop gains are fundamental to determining loop stability. Each element of a loop—the controller, the actuator, the process, and the transmitter—has a gain. If the slope of the graph relating its output to its input does not change, the gain of the element is constant and the element is said to be linear. If not, the response to an input change varies with operating point and this adds a non-linearity—a variable gain—to the loop.

The combined product of the individual element gains is the loop gain. If this product exceeds 1.0, the loop is unstable, and any oscillations initiated by an upset will grow. If the loop gain is less than 1.0, oscillations will decay to steady state. Tuning a controller means adjusting controller gain so that the combined loop gain is not so high that oscillations grow, or so low that the overall response is too sluggish.If any of the gain elements are not constant, loop gain is not constant, and loop stability will vary. For constant stability, the gain of a controller must be adjusted to compensate for any variations in the other gains in the loop that could increase the loop gain above 1.0. The essential questions are: Are the other gains in the loop constant, or do they vary? If they vary, you have to determine by how much, in what way, and for what reason.Each gain has a steady state value and a dynamic component. The steady state gain quantifies the ultimate effect of a step change in an input variable. The dynamic component quantifies the attenuation when the input is cycling.

Characteristics and conditions constancy

Typically, the gain of a transmitter is constant. Very often, the gain of an actuator is not. Valve characteristics, damper curves, and pump curves typically show a non-linear relationship between percent position and fluid flow. This will affect loop stability as the control signal to the actuator varies its operating point.The process characteristics that determine its gains also often vary. For the reactor that is the process for this series (see Inside Process section of Control Engineering , January 2005), the three curves in Figure 1 show how temperature varies when the steam changes step-wise, for high and low production rates, and when it cycles.

It should also be noted that, for this reactor, the final temperature response to a step change in steam flow varies inversely with throughput. When throughput is low, steam has a larger effect on output temperature.The dynamic characteristics of the reactor also depend on throughput. When throughput is low, the dead time in the response is longer since flow rate is slower.When the steam flow is cycling, the swing in the outlet temperature is not as large, even though the amplitude of the steam cycle is the same as the step, because the temperature never has time to reach steady state. The cycle attenuates the response.

This behavior is typical of many processes. Process gains often vary with production rate through its effect on dead times. At higher throughput, variables respond sooner and change less drastically. In gain terms, the process gain is lower, so controller gain can be higher and control can be tighter. Conversely, at lower rates the process is often harder to control, because variables respond later and more drastically. Process gain becomes larger, so loop gain is higher, and the process is unstable.Process gains also often change with operating points. Higher temperatures affect reaction rates and yields. Changing the set point for a product composition, or density, often affects its sensitivity to changes in ingredient flow rates. For level controls, changes in vessel geometry often affect level response.

For the reactor, the gain of the composition loop varies with its set point. As the set point approaches purity for either ingredient, the lesser component has a larger and larger effect on product purity. For example, at 99% A, a 1% change in the flow of ingredient B (at constant total flow) doubles the impurity in the product. Conversely, at 80% A, the same 1% increase in component B changes the impurity by only 1 part in 20. Large changes in the set point, perhaps for multiple products, often require retuning or compensation.

Dealing with variable gains

Advanced control begins with improving the performance of single loop controls in ways that address specific problems without changing loop structure.

For non-linearities in measurement signals and final actuators, the answer can be a characterizer that adds an opposing non-linearity to cancel the variable device gain. The stability of many loops can be improved using this well-developed, but often overlooked technique.

When the problem is variable process gains, several other techniques can be applied. The simplest approach is to tune the controller for the conditions at which the process gain is highest. This achieves stability, but at the cost of degraded response under all other conditions.

Other approaches that do not require modifying the loop structure include:

Gain scheduling: Virtually every DCS control algorithm allows adjusting a controller’s tuning constants as a function of some other variable. For the reactor, the proportional band of the temperature controller could be made to vary inversely with flow rate.

Non-linear gain compensation: Control functions in many DCS platforms include a standard non-linear option that characterizes the loop error. This option is most often applied for pH control, since the variation of pH with reagent flow is extremely non-linear. It is sometimes applied in level control to compensate for vessel geometry.

Self-tuning controllers: Most advanced DCS platforms include a self-tuning capability. These routines evaluate the current performance of a controller and modify its tuning constants to achieve a desirable transient response following an upset. This is a difficult challenge. The adaptor has to assume that any behavior it sees is the result of the changes it makes. As a result, such algorithms can be easily confused by cyclic oscillations that enter the loop through interaction with other variables. For example, any sustained oscillation in the flow rate would cause temperature variations at the same frequency. A self-tuner on the temperature controller would try, without success, to stop the temperature variation by detuning the temperature controller, leading to even worse temperature control. For such reasons, self-tuners need to be applied with close supervision and should not be left unattended for long periods.

Virtually all control loops are subject to variations that affect their gains and stability. The general concept that encompasses this concern is robustness1as a measure of the smallest change in any process parameter (from conditions at which the controller was tuned) that will cause an un-damped oscillation to be sustained in the loop.

In general, one goal of an advanced control strategy design is to make the control loop as robust as possible, by compensating or coping with those influences that change loop gains.

Feedforward control

But upsets will occur, and the controller must respond. Dealing with variable gains can only make the response to upsets more consistent. A second goal of advanced control is to more effectively respond to upsets which drive the controlled variables away from their set points.

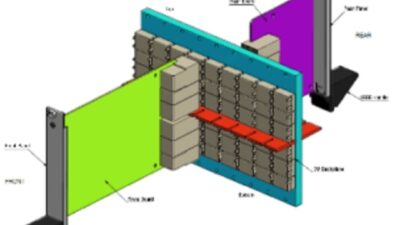

Figure 2 illustrates the problem for an automatic control loop. Many variables may affect the controller measurement, but only a limited number can be manipulated, and one of these must be assigned to the controller, as discussed in the previous article.

The others are, by definition, disturbance variables for this loop. Changes in these variables will affect the measurement, and the controller must vary its manipulated variable to compensate. In a simple feedback loop, as shown in the previous article, the controller remains unaware of these upsets until their effect on the controlled variables appears in the measurement signal. Unaware of the upset, the controller has to find the proper compensating output by trial and error. The oscillatory response of a feedback loop is the signature of this solution process.

Feedforward control provides a more informed approach to solving this problem. The goal is to use measurements of the other variable(s) affecting the controlled variable in a mathematical model that predicts and sets the value of the manipulated variable that will be required to hold the controller measurement constant.

But no model is perfect, and it is either impossible or impractical to measure many of the smaller influences. Allowance must also be made for transmitter error. So a feedback controller will still be required to provide a trim signal that can affect the calculation in a way that can eliminate the inevitable error resulting from simplification and transmitter error. Figure 3 shows the conceptual arrangement.

In the case of the reactor temperature loop, the measured disturbances are the flow rates of the ingredients manipulated to control product composition and production rate and the ingredient temperatures. Unmeasured disturbances include the steam properties and such factors as fouling and ambient conditions.

When the flow rate or temperature of either ingredient changes, the steam flow set point will also change, according to the feedforward equation (see sidebar for related equations). The system does not wait for a temperature error to appear at the feedback controller. For example, an increase in ingredient flow will drive the temperature down. A compensating increase in steam flow will drive the temperature up. Done properly, the effects will cancel and the outlet temperature can remain constant.

But one problem remains. Even if steam flow changes with ingredient flow, in the proper amount, the temperature will still show a transient error. This is because increases in ingredient flow drive the temperature down more quickly than increases in steam flow drive it up. The effects may cancel in steady state, and still differ dynamically.

Dynamic compensation addresses this issue. Including a lead function in the path to the steam flow set point makes up some of the ground lost before the effect of steam flow begins to appear, and minimizes the transient deviation from set point.2Figure 4 shows a diagram of the required mathematical functions.

References

Shinskey, F.G. Feedback Controllers in the Process Industries, McGraw-Hill Publishing, New York, 1994

Shinskey, F.G. Process Control Systems, 3rd edition, McGraw-Hill Publishing, New York, 1988

The next installment of this series will discuss decoupling control, implementation and performance of advanced regulatory control methods, and their impact on control room operators.

Online Extra

Regulatory Control article series

This series of articles presents the principles and compares the performance of several different control technologies against the same problem—control of a flow-through reactor. Basic and advanced regulatory control, rule based control, and model predictive control will all be applied. They will not all perform equally well. These performance differences will demonstrate how process characteristics ultimately dictate the most cost-effective solution for a control problem.

Techniques for economic optimization and proving control system performance round out the content of the series, which will conclude with a control technology selection guide and guidelines for achieving technical and economic success in a control project.

Author Information

Lew Gordon is a principal application engineer at Invensys;

Feedforward equations

Steady state material and energy balances provide the structure for the model. For example, for the reactor, a basic steady state energy balance (neglecting ambient losses and assuming saturated steam) can be stated as:

Heat given up by the condensing steam = heat transferred to ingredients A and B

This can be stated mathematically as:

F s H s = C p F a (T p – T a ) + C p F b (T p – T b )

where:

F s = flow rate of steam, lb/hr

H s = latent heat of steam/lb

C p = specific heat

F a = flow of A, gpm

T p = outlet temperature, °F

T a = inlet temperature of ingredient A, °F

F b = flow of B, gpm

T b = inlet temperature of ingredient B, °F

The feedforward design equation is simply the solution of this equation for the manipulated variable, F s.

F s = k[F a (T p – T a ) + F b (T p – T b )]

where the value of the constant, k, absorbs the physical constants and resolves all units. Substituting the nominal operating values provides its value.

20,000 = k [80 (125 – 50) + 20 (125 – 175)]

k = 4

Finally, to implement feedback trim, allow the feedback controller to adjust the target value for the product temperature.

F s = 4 [F a (T p a ) + F b (T p b )]

where

T p

The feedforward system is simply an implementation of this equation.