As a developer of networked, application-specific peripherals, Barix AG (Zurich, Switzerland) recently faced the problem of finding a way to network enable its universal, intelligent I/O device, Barionet, which is used for distributed data collection and control. The company wanted Barionet to have: multipurpose digital and analog I/O capability; serial connectivity; full TCP/IP stack implement...

As a developer of networked, application-specific peripherals, Barix AG (Zurich, Switzerland) recently faced the problem of finding a way to network enable its universal, intelligent I/O device, Barionet, which is used for distributed data collection and control. The company wanted Barionet to have: multipurpose digital and analog I/O capability; serial connectivity; full TCP/IP stack implementation; ability to upgrade firmware; and Web server with field-upgradable content.

Despite many available ‘network-enabling’ solutions, Barix’s development team knew that implementing the appropriate networking technology was critical to Barionet’s success. This I/O device had to be reliable and able to run in extended temperature ranges.

Barix’s developers eventually evaluated and implemented XPort, an embedded device server in a ruggedized RJ-45 package, from Lantronix (Irvine, CA), because of its:

-

Small form factor, which helped make room for Barionet’s many I/O interfaces, relays, and other bulky components;

-

Self-contained unit, which allowed use of one component from one manufacturer, rather than many physical, magnetic, and chip-level components;

-

EMC shielding. XPort simplifies product design because it is completely shielded and contains all ‘fast’ circuitry. Its few interface pins simplify EMC protection;

-

Board and layout simplicity. XPort allows developers to use a two- or four-sided PCB, which further simplifies board layouts;

-

Ease-of-use. Unlike standard network enabling solutions that often need multiple, high-pin out, fine-pitch semiconductors, XPort can be used even with through-hole designs, a standard form-factor.

Building versatile I/O

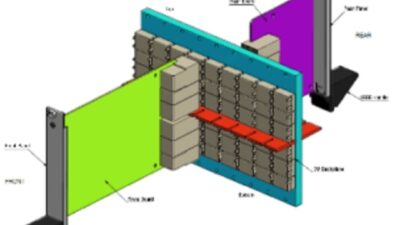

Barix’s Barionet I/O device is built from two major blocks: the I/O section and the network part, which now consists of just XPort. Barionet just needs power and a connection to its interfaces for operation. An independent I/O processor, Microchip PIC, handles the I/O part. PIC and XPort interface via a serial connection, with its speed set to a very high bit rate to allow for fast communication.

| To eliminate the complexity of creating a network-enabling solution, XPort embedded device server in an RJ-45 package includes a 10Base-T/100Base-TX Ethernet connection, a reliable operating system, an embedded Web server, flexible firmware, a full TCP/IP protocol stack, e-mail alerts, and optional 128-bit standards-based encryption. |

One important requirement was that users be able to upgrade Barionet in the field. This allows it to serve in many applications, depending on the software in the device.

In addition, Barionet’s four universal I/O pins can be software configured to act as analog inputs (0 to 10 V, 10-bit resolution); digital inputs (wide range, 0 to 12 V); or digital open collector outputs. Four more I/O pins have the same functionality, but without analog capability. Two relays offer 230 V ac, 5 A switching capability, and an expansion bus interface can be used for remote temperature sensors. PIC manages these I/O responsibilities, along with a small CPLD.

Also, being able to program Barionet by adding code to the XPort meant that PIC in Barionet could be upgraded with software via Ethernet interface. This allows Barionet to display the status of all inputs and outputs on an HTML page. Likewise, Barionet’s serial port can be daisy chained through PIC by using XPort’s serial interface.

Finally, by using XPort to network enable Barionet, Barix reports it was able to build a reliable product with much less effort than with a more traditional approach, such as a multi-chip, discrete solution. Besides significantly speeding up the design process, the required board space, board complexity, and EMC properties also were improved compared to usual methods.

For more information, www.lantronix.com Jim Montague, news editor