See 10 Ethernet-APL benefits, including technical specifications, test standards, and two-wire Ethernet physical layer components enabling deployment of high-speed communication field instruments in hazardous process automation environments, available after 3 years of work.

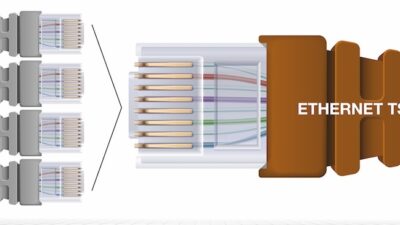

The 10Mbit/s Ethernet-APL standard, a two-wire, intrinsically safe, physical layer for process manufacturing industries, is complete after 3 years of cooperative development among leading standards development organizations and major process suppliers. Now available are Ethernet-APL standard technical specifications, test standards and two-wire Ethernet physical layer components enabling deployment of high-speed communication field instruments in hazardous process automation environments.

Ethernet-APL organizations, introduction participants

Standards development organizations FieldComm Group, ODVA, OPC Foundation, and Profibus and Profinet International (PI) and 12 major industrial project partners, worked for 3 years on “The APL Project” to create a new physical layer solution for field instrumentation. With the release of the specifications, engineering guidelines, and conformance test plans by The APL Project, end users can expect components from leading suppliers, with first products now available from select vendors. A June 15, press event at Achema, Frankfurt, Germany, provided Ethernet-APL details. Participants were Joerg Haehniche, Endress+Hauser innovation director; Adrienne Meyer, ODVA Inc. VP operations and membership; Dr. Al Beydoun, ODVA president and executive director; Stefan Hoppe, OPC Foundation president and executive director; Ted Masters, FieldComm Group president and CEO; Karsten Schneider, Profibus and Profinet International chairman.

10 Ethernet-APL benefits for process industries

Ethernet-APL technology resolves numerous barriers to deploying high-speed Ethernet enabled instrumentation in hazardous process automation facilities. Ethernet-APL improves communication speed, hazardous area reach, power to field instrumentation and long cable runs.

Ethernet-APL is an extension of the specification for single-pair Ethernet (SPE) based on 10BASET-1L, which can support every higher-order Ethernet communication protocol. Requirements necessary for reliable operation in process-related plants were satisfied by making adjustments to the physical layer, the. Reliable process plant industrial networks requirements and benefits include design advantages for process industries:

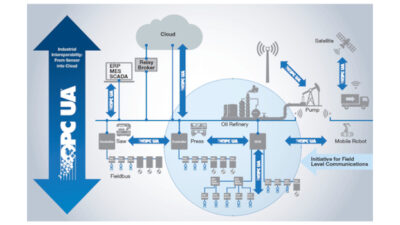

- High-speed Ethernet based communications. As a single physical layer, Ethernet-APL will be able to support EtherNet/IP, HART-IP, OPC UA, Profinet, or any other higher-level network protocol.

- Operation in potentially explosive areas. Electrical parameters that an Ethernet-APL device must meet to ensure “intrinsically safe” ignition protection are defined in the technical specification of the IEC TS 60079-47 (2-WISE or 2-Wire Intrinsically Safe Ethernet). The APL Project has defined port profiles to create the Ethernet-APL concept for multiple power levels with and without explosion hazardous area protection.

- The ability to install long cable lengths of up to 1,000 meters.

- Ethernet-APL port profiles. These include electrical power classes, shield connection options, and segment lengths, have been finalized.

- Framework for interoperability. Markings on devices and instrumentation will indicate power level and function as sourcing or sinking. This provides a simple framework for interoperability from engineering to operation and maintenance.

- Engineering guidelines and best practices for planning and installation are available in an engineering directive document that will support users when designing and commissioning networks using Ethernet-APL. This facilitates an easy transfer of knowledge for smooth Ethernet-APL adoption.

- Standard Ethernet diagnostic tools will assist new or seasoned instrument techs and engineers in their daily work, providing for a shallow learning curve.

- Activities are underway to finalize conformance testing at the leading standards development organizations that are a part of the APL Project. The test specifications now published will assure the quality of products and verify that a product complies with the parameters defined in the APL port profiles specification.

- The APL Project team has also cooperated with semiconductor manufacturers who will offer 10BASE-T1L Phys for Ethernet-APL on the market.

- Products: The 12 APL Project industry partners are finalizing development of products that will be available in the marketplace soon. The multivendor demonstration in Karlsruhe, Germany (displayed digitally during Achema Pulse showing participation across different product vendors and networks) highlights the multiple options and interoperability that Ethernet-APL will offer end users.

Cooperative statement from APL Steering Committee

“We are very pleased to release the carefully crafted technology specifications and engineering guidelines to enable Ethernet-APL technology to start to transform the field of process plants,” commented Dr. Jörg Hähniche, chair of the APL Steering Committee. “The high level of cooperation across multiple standards development and vendor organizations within the APL Project has resulted in one future oriented Ethernet physical layer for process automation. This technology launch is a key progress marker, and the development journey will continue now with products in the pipeline from significant industry partners.”

With the launch of Ethernet-APL, users can now anticipate one Ethernet physical layer that can enable long cable reach, intrinsic safety and application-level protocol support for maximum productivity and output, according to the Ethernet-APL organization. Products are promised soon with conformance testing certification, those involved said. Ethernet-APL provides more information in a “Ethernet to the Field” white paper in Adobe .PDF format.

Mark T. Hoske, content manager, Control Engineering, CFE Media, [email protected].

KEYWORDS: Ethernet-APL, process industries, process manufacturing

Ethernet-APL standard is two-wire, 10Mbit/s Ethernet for process industries.

See 10 benefits of Ethernet-APL.

Ethernet-APL resulted from 3 years of cooperation from four standards development organizations and 12 process industry suppliers.

CONSIDER THIS

What Ethernet-APL benefits will your organization see?

ONLINE EXTRA

See prior articles linked below.

More about the standards organizations follow.

About FieldComm Group: FieldComm Group is a global standards-based organization of process end users, manufacturers, universities and research organizations that work together to direct the development, incorporation and implementation of new and overlapping technologies and serves as the source for FieldComm Group FDI technology. FieldComm Group’s mission is to develop, manage and promote global standards for integrating digital devices into automation system architectures while protecting process-automation investments in FieldComm Group’s HART and Foundation Fieldbus communication technologies. Membership is open to anyone interested in the use of the technologies. www.FieldCommgroup.org

About ODVA: ODVA is an international standards development and trade organization with members from automation suppliers. ODVA’s mission is to advance open, interoperable information and communication technologies for industrial automation. Its standards include the Common Industrial Protocol or ODVA CIP, ODVA’s media independent network protocol, and industrial communication technologies including ODVA EtherNet/IP, DeviceNet and others. For interoperability of production systems and their integration with other systems, ODVA embraces the adoption of commercial-off-the-shelf, standard Internet and Ethernet technologies as a guiding principle, exemplified by ODVA EtherNet/IP. www.odva.org

About the OPC Foundation: Since 1996, the OPC Foundation has facilitated the development and adoption of the OPC information exchange standards. As advocate and custodian of these specifications, the Foundation’s mission is to help industry vendors, end-users, and software developers maintain interoperability in their manufacturing and automation assets. The OPC Foundation is dedicated to providing specifications, technology, process, and certification to achieve multivendor, multiplatform, secure, reliable, interoperability for moving data and information from the embedded world to the enterprise cloud. The OPC Foundation serves more than 815 members worldwide in the industrial automation, information technology (IT), Internet of Things (IoT), Industrial Internet of Things (IIoT), machine to machine (M2M), Industrie 4.0 (Industry 4.0), building automation, machine tools, pharmaceutical, petrochemical, and smart energy sectors. www.opcfoundation.org

About Profibus and Profinet International (PI): PI is an automation community represented by 25 regional PI associations and is responsible Profibus and Profinet, two industrial communications protocols covering all industries. The common interest of PI’s global network of vendors, developers, system integrators and end users is to promote, support and use Profibus and Profinet. More than 1,500 member companies globally work closely on automation. www.profibus.com

OPC UA: wider controller communications with TSN, APL

Single pair Ethernet standard targets OT networks