Industrial connectivity products and services including a pre-integrated control panel, Ethernet switches, controllers, input/output (I/O) modules and human-machine interface (HMI) were part of the Wago Corp. booth at Automate 2024 by A3.

Learning Objectives

- Explore products and services that Wago Corp. highlighted at the Automate 2024 event, including industrial connectivity products and services including a pre-integrated control panel, ethernet switches, controllers, input/output (I/O) modules and human-machine interface (HMI).

- Review fast, safe and reliable industrial connectivity solutions and value-added services explained in the booth tour, including photos.

Automate 2024: industrial connectivity, controllers, communication insights

- Wago Corp., at the Automate 2024 event, showed industrial connectivity products and services including a pre-integrated control panel, ethernet switches, controllers, input/output (I/O) modules and human-machine interface (HMI).

- Fast, safe and reliable industrial connectivity solutions and value-added services were explained in the booth tour, including photos.

Industrial automation applications can benefit from a variety of products and services such as control panel design and integration, input/output (I/O) modules Ethernet switches, controllers, power supplies and human-machine interfaces (HMI), as shown by Wago Corp. at Automate 2024 event by A3, the Association for Advancing Automation, in Chicago.

Automate 2024 Wago booth tour: Controls, communications, connectivity

Robb Perez, regional sales manager, Wago Corp., provided an Automate 2024 booth tour, discussing a variety of fast, safe and reliable connectivity solutions and value-added services, including:

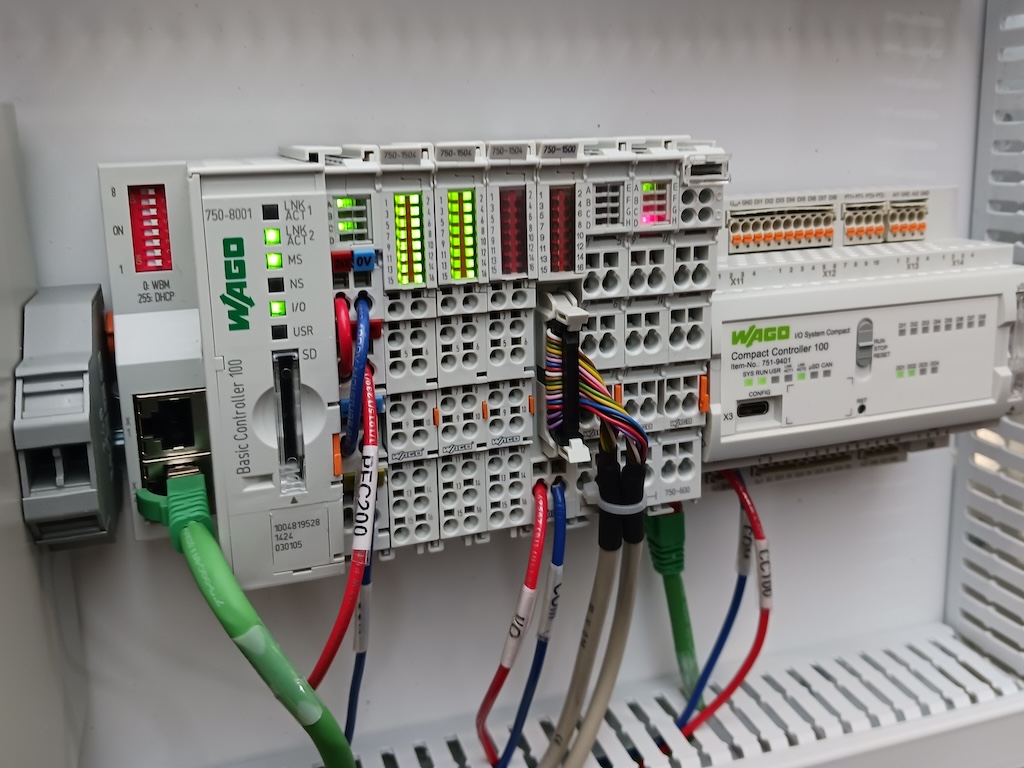

Mini control panel includes PLC, communications, relays, fuse holder, terminal blocks and slice I/O modules, with more than 200 I/O options available. An online configurator for pre-integration services allows panel design with 3D modeling and file export in .DWG and .DXF formats.

Lean managed Ethernet switches have 16 (10/100/1000Base-T) ports, redundant power supply and relay-based function monitoring. Commissioning and diagnostics are said to be intuitive without extensive IT knowledge. Software to manage each point shows the topology map, switch and connected devices. Security is via network segmentation per IEEE802.1Q (max. 5 VLANs), authentication of network participants per IEEE802.1X, firewall functions using access-control list (maximum 32 entries)/service control, port security. Encrypt critical Ethernet information. Rapid spanning tree protocol (RSTP) for meshed and ring networks is available.

IO-Link Converter has 8 configurable digital I/O ports to connect IO-Link communications to Profinet. A stainless-steel body has epoxy filling and nickel plating, IP67 rating. The unit has Bluetooth capability, a QR code to download appropriate configuration software application and is compatible with the Wago printer application for easy labeling.

XTR Series Controllers have a design that fits extreme applications, such as aerospace and railway or any high-vibration environment. It uses the Wago Cage Clamp wire fastening system to help ensure wired connections stay in place.

Eco 2 slim-style, 50 mm, 240W lever-operated power supply is said to be economical, with 93% efficiency rating and -25 to 70 degrees C operating temperature range. It has 1-phase, 100 to 240 VAC, 50/60 Hz input and 24 VDC, 10 A and 240W output.

Pro 2 power supply has TopBoost and PowerBoost technologies that can offer more current for motor-starting needs. Communication modules are available for Modbus TCP, EtherNet/IP (ODVA), Profinet and Message Queuing and Telemetry Transport (MQTT) industrial networking.

Compact Controller 100 (CC100) brick-style PLC has onboard I/O (8 digital inputs, 4 digital inputs, 2 analog inputs and 2 analog outputs), 2 remote terminal device (RTD) ports, onboard power and a USB-C port for laptop connection. CODESYS version 3 software offers advanced programming capabilities and software development.

2600 Series PCB terminal blocks (1-9 ports) use the Wago tool-less wire termination system, using a lever to connect what otherwise is a normally closed point for 4 to 20-gauge wire.

TouchPanel 600 HMI with multi-capacitive touch is available with screen sizes 4.3- to 21.5-in., in standard, advanced and marine (rated for water) designs. It provides controller visualization and can replace analog buttons on a control panel. Three families are web Panel, Visu Panel and Control Panel.

IEEE 1547-2018 Compliant Controller

Wago described the IEEE 1547-2018 Compliant Controller in an press release before the Automate 2024 event. The new Wago Distributed Energy Resources (DER) Controller is a library function block with a control algorithm for voltage, frequency and reactive power control. To ensure a reliable power system, the DER connection to the grid requires communication between the energy source and the operator. Standards like IEEE 1547-2018 have been implemented to provide a trouble-free connection between systems.

Of the 11 clauses related to IEEE 1547-2018, the Wago DER supports clauses 5 and 10. Clause 5 deals with reactive power and voltage/power control. This reinforces Clause 10 which handles the subject of interoperability for information exchange. The library function block in these controllers is programmed with CODESYS 3.5 software and has been validated and verified by a Nationally Recognized Testing Laboratory.

Also: See interview with Charles Norz from Wago here:

Mark T. Hoske, editor-in-chief, Control Engineering, WTWH Media, [email protected] with information from a Wago booth tour and online press releases.

KEYWORDS

Automate 2024, I/O modules, industrial controllers

CONSIDER THIS

Could your control panel design benefit from design and configuration software and updated controllers, connectivity and communications.