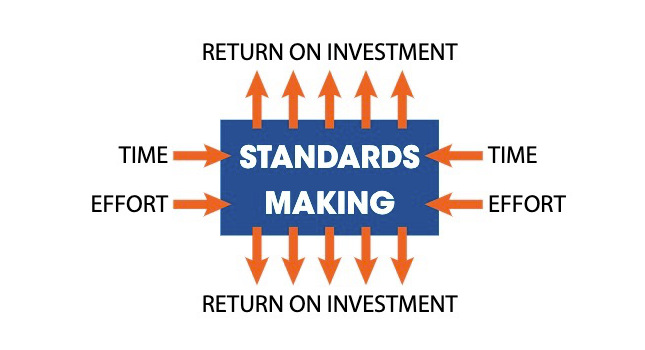

Analysis: While the measure of standards organizations, end users, and suppliers have differed in the past, the future requires collaboration to help standards enhance return on investment for technologies used in factory automation and process automation.

How can the value proposition of standards be measured for standards organization, end users, and technology suppliers?

1. For standards organizations developing open standards, the real value proposition is measuring success by the level of adoption. Standards organizations help drive technologies and play a very important role in contributing to new and emerging technologies and how they are deployed across industries. The focus of standard organizations in the ever changing world of technology is to deliver standards, technology, process and certification focused at solving real world problems.

2. For end users to prepare for numerous technical innovations beyond the horizon, the most important technology and standards strategy is working closely with suppliers to identify and develop the right standards to achieve success in factory automation and process automation. Benefits derive from collaborating to develop a complete open system architecture or by standardizing on the data and information models for their respective industries. A number of initiatives involve suppliers working under the direction of end-users and end-user organizations.

3. For suppliers, integrating useful standards into products helps enhance customer return on investment (ROI) and makes suppliers’ products, software and services more useful. Suppliers know that to be competitive they must deliver products and services that embrace interoperability with their competitors. The end-users have diverse sets of requirements for automation, and typically have hardware, networks and software products from a multitude of different companies. The days of a single vendor and single network being used by an end-user are gone. End-users also need integration between IT and OT systems and the value of standards play a very important role in IT and OT convergence.

Standards integration

Ten years ago, NAMUR was a driving force across process industries to standardize on device configuration and asset management. Every major process automation supplier was involved in this effort, contributing significant amounts of resources in money and people to develop a standard and to make standards jointly owned by the standards organizations. One specific standardization activity was FDI, and the standards organizations involved in this included OPC Foundation and organizations for FDT, Profinet, Foundation Fieldbus, and HART.

A multiple-year effort helped suppliers to deliver a standardized device model to end users. The resulting technology is being used by distributed control system (DCS) vendors, and is managed by the FieldComm Group. (See related FieldComm Group article.)

Usable standards

Standards organizations used to be in business to just develop standards and often did not deliver a standard that was worth more than the “paper” it was printed on. Often standards were developed as a means to an end by a single supplier. One supplier would partner with other companies for the primary purpose of adopting the standard they were developing. Over the years, many standards organizations recognized the need to develop standards that suppliers would widely use in products and systems. Success of standards in consumer industries has had a significant impact on standards organizations and in industrial automation.

IT, OT convergence

Other developments feeding more effective standards include:

- Popularity of solution strategies

- Convergence of information technology (IT) and operations technology (OT)

- Ability to integrate data from the OT world (factory floor, for example) into the IT applications.

OT and IT worlds differ, but both sides have recognized the need for integrating data and information among and between their systems. Industry standards play a very important role in IT and OT convergence.

Examples of end user and supplier collaboration include initiatives and standardization like MDIS, open process automation, Open-SCS, VDMA, OMAC, and MTConnect. The OPC Foundation recognized the importance of collaborating with standards organizations that were involved in developing their own information models for their respective industries. The OPC UA architecture facilitates these standard organizations developing companion specifications to integrate their information models into the OPC UA infrastructure.

Standards organizations need to recognize the reason they are in business: To have their technologies adopted, solve real-world problems for end users and suppliers and provide ROI. Standards must not be academic futility and standards organizations need not compete. Many opportunities exist to pursue standards convergence and harmonization.

Successful standardization in consumer electronics resulted in standards adopted by suppliers and used in products that end users want. Industrial end users and suppliers are overwhelmed by a multitude of available technical innovations available. Therefore, it is important harmonization and standardization is achieved. Standards and technologies need to solve real-world problems to be relevant.

Standards, interoperability, value

There are many opportunities for standards that allow true plug-and-play interoperability and leverage technologies involved in adaptive learning and machine learning. Older programming models for many devices have changed as technology has advanced and programming environments have standardized and commoditized.

Multiple standards organizations compete for space as they recognize the importance of harmonization. If they want to be successful, they must be developing the right standards and technologies that will be adopted into products and deployed by end users.

Thomas J. Burke is global director of industry standards at Mitsubishi Electric Automation Inc. and past president and executive director of the OPC Foundation. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media, [email protected].

KEYWORDS: Industrial networking standards, interoperability, IT/OT collaboration

Standards organizations help drive technologies and contribute to new and emerging technologies and how they are deployed.

Operations technology (OT) and information technology (IT) users recognize the need to collaborate and harmonize through common standards.

Organizations need to develop the right standards to be relevant for end users and manufacturers.

CONSIDER THIS

What is the biggest challenge for your organization as standards and networking technologies converge?