As companies look to diversify to help improve sustainability, robot programming that is simple enough to be refigured to any kind of manufacturing environment is critical.

There are challenges ahead for manufacturing – against pressures to recover in the wake of the COVID-19 pandemic and, to this end, to diversify and explore new revenue streams. Both goals require sustainability.

According to the study “Achieving Sustainability in Manufacturing Using Robotic Methodologies” by the Department of Industrial Engineering, Tshwane University, South Africa: “Sustainability is the ability to develop and implement technologies/methodologies, which are self-sustaining without jeopardizing the potential for future generation to meet their needs.”

Industrial robots are helping manufacturers reach their goals of better plant performance and lower production costs. Tshwane University’s report highlights several goals that robots in manufacturing can help achieve, including “Adaptability to a new task; automatically compensating for limited variability [and] meeting safety requirements.”

Robots can help achieve these things – but they still need the support of human workers in order to do so. A report by Brazil’s Federal University of Technology – Paraná (UTFPR), Human Factor in Smart Industry: A Literature Review, puts it well: ‘Human work will be indispensable in smart industries, both for the development of this concept as the management and operationalisation of advanced production systems, technologies and processes.’

Companies must adapt the capabilities of high- or low-skilled workers to get the most of out robots. This is also important to self-sustainability.

Easy programming

Self-sustainability means that the working systems between robots and humans can continue to function and grow into the future. Indeed, for manufacturers a key signifier of growth is acquiring more machines that also have more capabilities – for example ceiling mounted robots, robot 3D vision systems and more.

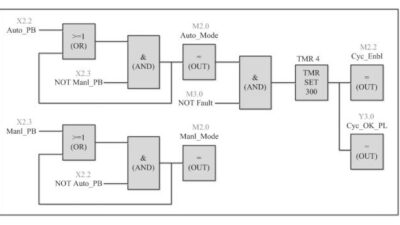

To achieve this, Tshwane University’s report states that robots must have the ‘ability to be easily programmed by shop-floor workers.’ Other factors include easier-to-use human-machine interfaces (HMIs) and less skill-intensive control.

Not only must these programming systems be future-proof, to support future robot purchases and overall self-sustainability, they must also complement existing processes.

This is where an industrial robot programming tool can prove valuable. The software is designed for many robots and offers powerful assistance to all phases of automation. Importantly, this covers all phases of automation – from planning and installation to enhancement.

The programming tool helps both low-skilled and high-skilled workers to get involved with programming and learn how to equip SCARA robots for continuous operation. It is also used to upload and download program and parameter files, generate 3D simulations, perform checks and includes an updated graphical user interface.

Diversify to survive

This brings us to diversification within sustainability. Robots are not limited to working on a single task, but rather can be used in connection with different tasks and levels of difficulty. Machine shops can therefore balance the requirements of diversification while doing so cost-effectively. TSAssist can support this by bringing numerous functions into one place, from interference checking and cycle time measurement to accurate 3D CAD manipulation with perfect calibration.

With easier programming, manufacturers can better explore and exploit the sustainable and environmental advantages of integrating automation and energy-efficient SCARA robots into their manufacturing processes.

This article originally appeared on Control Engineering Europe’s website. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media, [email protected].