Original equipment manufacturers (OEMs), machine builders and others can access a no-code Industrial Internet of Things (IIoT) cloud platform, providing easy-to-use data analysis tools, other functionality for bottom-line improvements

Learning Objectives

- Cloud service enables easy PLC data harvesting, dashboard displays.

- PLC data can be used for machine analytics.

- Machine performance KPIs can be used for comparative fleet analytics with rich cybersecurity features.

Machine builders can raise design efficiency by using cloud-based Industrial Internet of Things software capabilities, building secure and scalable dashboards for customers. By using cloud-based capabilities from a machine builder’s supplier for programmable logic controllers (PLCs) and human-machine interface (HMI), input-output (I/O) devices, variable frequency drives (VFDs) and motors, machine builders can quickly access, in less than 30 minutes, data analysis tools to speed commissioning by using a no-coding-needed software.

PLC data harvesting, easy dashboard displays

PLC application data can be harvested, analyzed and leveraged to increase efficiency, troubleshoot problems and implement preventive maintenance. These can reduce management overhead, leaving more time to expand business operations.

Available capabilities in such software include multi-lingual dashboards by using drag-and-drop tools, without programming. Dashboards can be customized with branding with logo and colors in line with the machine builder’s brands.

Users can create and assign roles and personalized dashboards as needed. Those with appropriate security clearance can access, monitor and trouble-shoot machines. Operational machine data can be managed for performance-related analysis.

Use PLC data for machine analytics

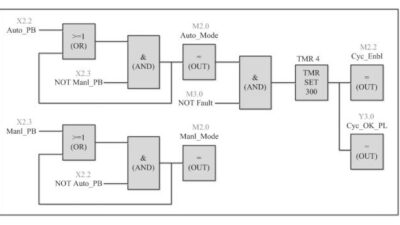

By using integrate IIoT capabilities in cloud services, key machine data from the PLC can harvested. Key performance indicators (KPIs) can be determined with centralized and aggregated data. Such data can be used to monitor and improve process reliability, reduce operational and maintenance costs, predict failures, minimize unplanned slowdowns and shutdowns and generate revenue. Machine builders can use information to locate sales opportunities for complementary products, consumables and services. By using built-in cloud infrastructure, interfaces and functionality, it’s easier to setup and commission a system using a simple drag and drop interface; with a software as a service (SaaS), there’s no need to install software components, database management services or hardware. Wizards in software can help customize data displays, and the cloud software integrates with PLCs.

Comparative fleet analytics, KPIs, cybersecurity

When a machine builder uses data from many machines, comparative data can be used to improve designs, improve maintenance and help customers more effectively. They can look at KPIs over time, at one site, many sites, regionally or globally. During the pandemic, intelligence about machine performance can maximize remote troubleshooting and limit travel to the most-essential events, minimize risk.

With increased connectivity needs, machine builders seek to minimize cybersecurity risk. Using a cloud-based architecture with multilayered security at its backbone can use such tools as:

- Encrypted data at REST and in Transit

- Encrypted REST APIs over TLS

- MQTT X.509 certificate authentication

- Protected with strict WAF rules against common attack patterns such as SQL injections, cross-side scripting, and other attacks

- AWS resources audited via CloudTail

- Anti-virus that runs on all machines

- Application security with role-based authentication, strict password policy

- Secure remote access machines for remote maintenance with virtual network computing (VNC) to enables secure access to a PLC’s HMI via the PLC webserver with a secure, private connection.

- 24/7 monitoring from a human operations center to handle any security threats and performance issues.

Edited from a Unitronics UniCloud press release by Mark T. Hoske, content manager, Control Engineering, CFE Media and technology, [email protected].

KEYWORDS: IIoT, cloud analytics

Cloud service enables easy PLC data harvesting, dashboard displays.

PLC data can be used for machine analytics.

Machine performance KPIs can be used for comparative fleet analytics with rich cybersecurity features.

CONSIDER THIS

If you haven’t added IIoT cloud-based functionality yet, would a no-programming software as a service (SaaS) help?

ONLINE extra

More information is available from Unitronics about UniCloud.