Siemens Energy & Automation Safety Innovation Tour is bringing U.S. cities live demonstrations and seminars on how to seamlessly integrate certified safety protection into a company's automation architecture. New wireless safety products also are shown.

As part of its ongoing effort to bring technology and solutions directly to its customers, Siemens Energy & Automation Inc. has launched a Safety Innovation Tour. The tour is visiting cities across the United States. It features live demonstrations and seminars on how to seamlessly integrate certified safety protection into a company’s automation architecture. Safety related systems are increasingly important to manufacturing processes .

|

Wireless safety advice Siemens says it is critical to realize that wireless is already being implemented in control applications even in areas as sensitive as safety. Offering advice on " 7 critical things to know before implementing wireless on the plant floor ," Siemens says: "Control over wireless using IEEE 802.11 is now a reality. Gantry robots and automated guided vehicles (AGVs) are being used in a wide variety of pick and place applications in many industries. Most machines with moving parts are outfitted with light curtains or laser scanners to protect personnel working on or near the machine and to provide better positioning accuracy. Using 802.11 wireless technology in combination with safety protocols and failsafe PLCs can reduce cabling costs, maintenance times and shorten downtimes in these sensitive applications." |

Additionally, SE&A will demonstrate two new wireless safety products.

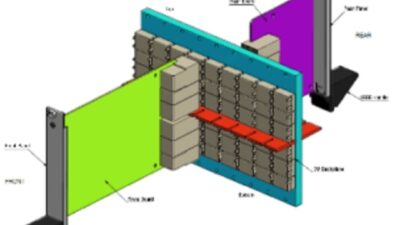

Attendees will be introduced to a web-based tool that evaluates the actual safety level achieved per the new safety standards. They will also see demonstrations of the latest innovations in safety bus technologies from a simple device bus up to real time Ethernet; including wireless solutions will be demonstrated. The events will also introduce safety integrated into PC-based automation.

The tour will showcase safety rated drives with safe motion, safety controller with integrated Web access, all on a single bus to operator panels and plant wide operation. Whether the application requires a single safety relay, a complex safety solution of coordinated control or anything in between, attendees will see solutions demonstrated that can save engineering time and maintenance costs while improving machine efficiency.

Sessions cover safety topics including:

• PC-based safety;

• Basic of new safety standards

• Safety rated drives with safe limited speed

• Simple integrated message functions

• Embedded diagnostic web pages

• HMI showing detailed fault location of the safety functions

• Safe Ethernet communications

• Wireless safety communications

• Simple drive networking

• Safety networking with AS-Interface

• Programmable safety relays

These no-cost events are an opportunity to learn from the experts in safety automation, share best practices and learn about the latest technology trends. Siemens provides an updated list of safety tour cities, dates and times .

– Edited by Mark T. Hoske, electronic products editor, MBT www.mbtmag.com