The common perception is that temperature control is a mature and largely unchanging area of technology. There are still industrial applications (for example, injection molding processes), which desire not only precise temperature control, but also a faster warm-up phase and quicker response to disturbances with minimal overshoot and undershoot when the setpoint changes.

The common perception is that temperature control is a mature and largely unchanging area of technology. There are still industrial applications (for example, injection molding processes), which desire not only precise temperature control, but also a faster warm-up phase and quicker response to disturbances with minimal overshoot and undershoot when the setpoint changes. Traditional proportional-integral-derivative (PID) control techniques cannot meet these extra challenges.

Basically two directions exist for designing highly sophisticated temperature controllers. One solution is based on adding special features not found in traditional PID controllers and the other solution is based on using fuzzy logic control.

Enhance PID temperature controller design

A different speed (that is, a time constant) of the heating and cooling processes needs dynamical adaptation of the PID constants according to the temperature setpoint value. Such an adaptation requires a heater model—an inverse static characteristic of the heating process. Once the control system implements the heating model, its output can be used suitably as a feedforward variable. The feedforward variable together with the output of the integral member can, on the other hand, help the heater model learn more about the heating process.

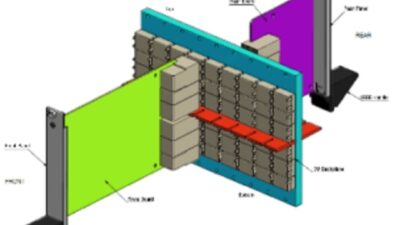

An approximation of the time optimal control method requires splitting the total range of temperature control into three ranges with different control mechanisms acting in each. In the first range (for temperatures well below the setpoint value) and the last range (for temperatures well above the setpoint), a constant (full or zero, respectively) power is applied and the regulation error integration is put on hold. In the middle range (with the setpoint value in the center), a linear PID control is acting. In this, so-called linear control zone (LCZ), another nonlinearity, regulation error limit (REL) can be used—it will help to limit the temperature over/undershoot. Figure 1 shows a block diagram of an enhanced PID temperature controller, suitable for the most demanding applications.

Fuzzy logic

Figure 1

The principles of fuzzy logic have been known among engineers for more than 35 years. Fuzzy control (i.e., fuzzy logic in the role of a control system) becomes attractive especially for the smallest microcontrollers, because this technique requires less computational power and demands less operational memory than conventional PID compensation.

Figure 2

Fuzzy control in its basic form mimics a man ual control process. A person regulates power applied to a heating element according to the momentary temperature deviation from the setpoint value (the regulation error, e(n)) and the rate of the temperature change (or derivative of the regulation error, (e(n)). The entire process is governed more by a sense than by the knowledge of its physical or mathematical behavior. Are the temperature deviation and the rate of the temperature change high, low, or medium? Fuzzy control works exactly with the same states of the process variables.

The block diagram of the fuzzy temperature controller (Figure 2) shows how the output of the fuzzy controller is combined with the output of the feedforward module, as in the case of an enhanced traditional PID controller. A similar adapter module optimizes the defuzzification process (mapping of the fuzzified output variable into its crisp output value) and concurrently helps the heater model learn more about the heating process.

Making the decision

Even a simple process like the temperature control can become a complex task if additional features like fast warm-up phase are needed. Implementing the enhanced, traditional PID controller can be a challenge, especially if auto-tuning capabilities to help find the optimal PID constants are desired. However, the theory of PID control is very well known and widely used in many other control applications.

On the other hand, fuzzy control seems to accomplish the same control quality with less complexity. Approximation of the second-order switching curve used in time-optimal control systems by a polynomial of the first or higher order (LCZ in the enhanced PID control provides only a zero-order approximation) makes fuzzy control a better candidate for time-optimal control applications. As a relatively new control method it provides more space for further improvements.

Author Information

Peter Galan is a control software engineer with Nortel Networks