A human-machine interface (HMI) establishes a machine builder’s brand, which makes any upgrade require a balance of optimal user experience, hardware options and upstream communication.

Learning Objectives

- The modern human-machine interface (HMI) should be created with a modern user experience (UX) design in mind.

- HMI screens and bodies should be designed to be tough and able to withstand damage in hazardous and harsh environments.

- Modern HMIs should deliver the upstream connectivity necessary for manufacturers to calculate overall equipment effectiveness (OEE).

The most important aspect of any original equipment manufacturer’s (OEM’s) brand probably wouldn’t make most people’s top 10 list. The human-machine interface (HMI) is the most critical component for ensuring a positive relationship with a machine builder’s brand. This key combination of hardware and software is the first impression a customer has of the machine’s functionality and ease of use. However, it’s often the last aspect considered in an application, and many companies slap on the same drab plastic panels that are as exciting as an analog TV.

Let’s explore why this is, and what you can do about it, whether you work for a machine builder, system integrator or end user of equipment. To help evaluate any HMI update, it’s helpful to consider three effective HMI design pillars.

Pillar 1: Software geared toward UX, mobility, safety, flexibility

Much has been said about the iPad generation. The rise of tablets and smartphones has played a major role in setting user experience (UX) expectations, even in industrial settings. Back in the day, machine operators had to receive extensive maintenance training and rely on PLC programming knowledge to make changes to (or just make sense of) cryptic interfaces with limited troubleshooting assistance. With today’s continued labor shortages and reduced automation expertise on the plant floor, that’s not an option. Despite these harsh realities, this was never a good approach to machine operation due to unnecessary downtime.

Any contemporary HMI should offer simple, intuitive software navigation with fewer pages to navigate and multi-touch functionality to find everything faster. The design, on-screen text and labels should be created for users to understand in their local languages, with easy-to-understand terminology, controls and troubleshooting measures. There should be no “engineer speak” in the headings, and the HMI should offer variable parameters to allow non-programmers to make changes intuitively without having to get anywhere near a PLC to edit the machine code.

Developments in web-based HMI open more possibilities for machine operators. This takes the bring your own device (BYOD) approach to the plant floor. With HMI software built using modern web development standards such as HTML5 and JavaScript, OEMs can implement responsive HMI software that automatically scales and reformats based on any piece of glass – whether it’s the industrial HMI in landscape or portrait orientation or those previously mentioned smartphones and tablets. The ability to take a machine’s HMI anywhere communicates a clear “wow” factor and top-shelf flexibility for the machine’s authorized operators.

Beyond usability, a better HMI helps users manage parameter changes consistently, ensuring no damage is done and safety protocols remain in place. A modern UX also enhances diagnostics, giving more context to error codes and helping users quickly troubleshoot problems. You can even embed instruction videos or PDF documentation – for example, how to fix material feed issues on a vertical form fill seal (VFFS) machine. The more actionable information at the machine that’s easy for everyone to understand, the greater time savings and overall equipment effectiveness (OEE).

Pillar 2: Hardware for durability, appearance

The main operator interface hardware on the machine must be tough. Screens must be resilient to constant use and harsh environments where bumps, scrapes and blunt force mishaps are all possible. HMI designs today incorporate all-metal housings that are either milled out of solid blocks of aluminum or encased in steel. This ensures the displays can take more damage compared to plastic panels, which are flimsier and more prone to cracking and breaking.

Panels with rugged metal housings also should be ruggedized for constant vibration and extreme temperatures. For wet, dusty and messy applications such as food, beverage and pharmaceutical production, IP65-rated panels with stainless steel housings and bezels can get wet and be wiped down in typical hygienic cleaning processes.

Some machine builders and integrators may think their only choices are between vanilla and vanilla for their HMI screens, but vendors can offer a comprehensive array of screen sizes and orientations. While offering better looking, more durable and more reliable panels, there also are vendors that offer durable HMI hardware with screens from 5.7-in. up to 24-in.. Widescreen formats have become quite popular, but it’s just as possible to standardize on panels in portrait orientation in several screen sizes.

However, some vendors understand older formats such as 4:3 are preferred by some machine builders and continue to offer options. There also are options to include capacitive multitouch functionality in almost all screen sizes and orientations to keep up with all the exciting developments previously discussed in HMI software.

While it’s important to ensure that HMI hardware is designed for rugged operation in the here and now, choose vendors that can ensure long-term reliability and availability so the hardware can last within the typically long lifecycles of machinery installed in the field. This reduces redesign requirements and helps make any HMI maintenance, repair or replacement with the same hardware viable for decades.

Pillar 3: Upstream communication, OEE, MES, AI, ML

Functionality shouldn’t stop at the plant floor, not even at the remote machine control level. Modern HMIs should deliver the upstream connectivity necessary for manufacturers to create real business intelligence or calculateOEE, adding value for end users. This includes the ability to send information from the machine upstream for evaluation at the supervisory control and data acquisition (SCADA), manufacturing execution software (MES) or enterprise levels. It also could encompass using artificial intelligence (AI) or machine learning (ML) to optimize performance, throughput or energy efficiency.

The power of the overall automation platform is as important as the HMI software. Users need to ask questions about its capabilities including:

- Can the system pull data from across the machine or plant – over EtherCAT, EtherNet/IP, Profinet or other networks in the field, plus vertically with message queuing telemetry transport (MQTT), OPC UA, etc.?

- Can you bring a newly optimized control algorithm down via ML and implement it on your line quickly?

- Can you securely log into machines installed around the world for remote service?

As the digitization of manufacturing accelerates, HMI can no longer be a static menu. It needs to be a gateway from the plant floor to the cloud and promote harmony of machine-level systems with higher-level operations.

Speaking of digital transformation, that mundane dynamic of having operators and maintenance personnel trudge back and forth between the HMI and the PLC to figure out an error code is no longer viable.

Choose HMI technology wisely

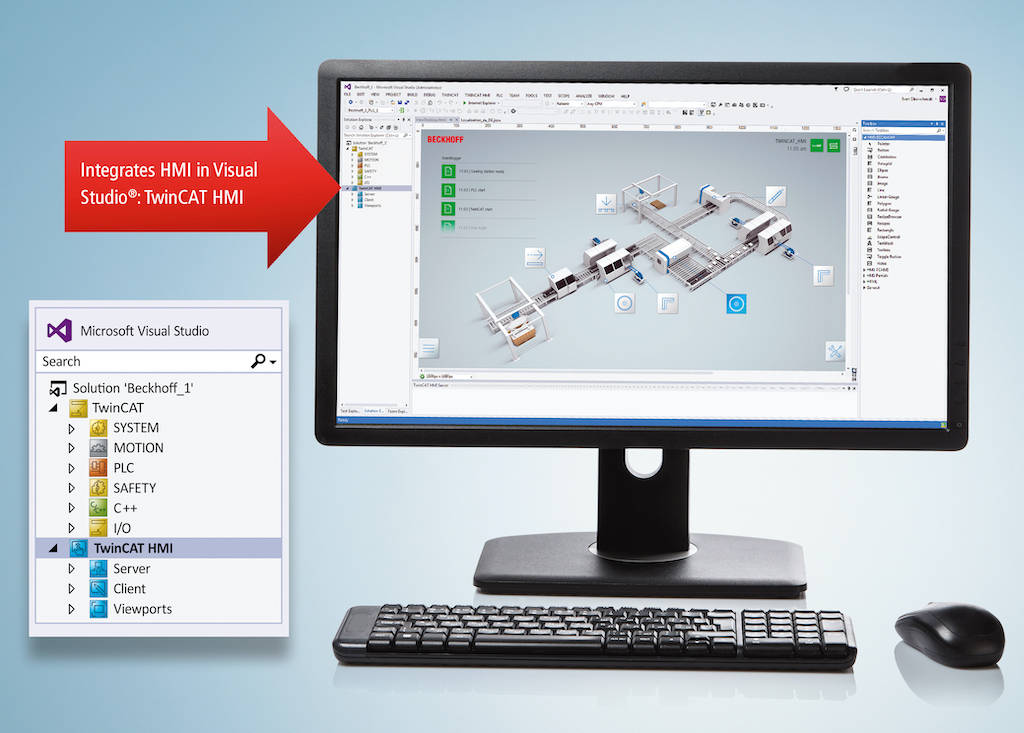

So what does all this look like for the controls engineer? They should seek out HMI software that allows for programming in HTML5 and other common web-design standards. Software also should offer superior portability with ability to run the same program on the next generation of hardware, rather than needing to write a new program every time a change is needed. Get bonus points if all this is integrated into a universal automation platform and engineering environment that encompasses everything, including HMI, PLC, robot kinematics and IoT. The resulting differences – on the exterior and under the hood – can make a huge difference for end users.

Rick Forsgren, packaging industry specialist, Beckhoff Automation LLC. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, [email protected].

MORE ANSWERS

Keywords: human-machine interface, HMI, HMI automation

ONLINE EXTRA

For more information:

CONSIDER THIS

What do you look for in a modern HMI?