Open automation ecosystems help resolve workforce challenges and provides metrics such as a 50% downtime reduction and a 20% increase in overall equipment effectiveness (OEE) over two years, according to an Automate 2025 keynote presentation.

Open automation impacts workforce insights

- Aamir Paul, president, North America Operations, Schneider Electric discussed “Redefining industry: A bold new era for American manufacturing and the opportunities it creates for the American workforce” in a keynote session during Automate 2025.

- Explore how industrial automation will impact the workforce today and tomorrow and what do different generations need from automation in their daily jobs.

- Understand what open automation means for the jobs of tomorrow’s workforce and which industries can benefit and can scale quickly?

Open, software-based industrial automation is helping the workforce of today and tomorrow, across generations of workers and helping industries fill the skilled workforce gap, improve safety, quality, sustainability and profitability, according to Aamir Paul, president, North America Operations, Schneider Electric[LINK www.se.com] (Figure 1). His keynote session, “Redefining industry: A bold new era for American manufacturing and the opportunities it creates for the American workforce” was part of Automate 2025[link www.automateshow.com]. The show and conference from Association for Advancing Automation (A3) in Detroit, May 12-16, touted more than 875 exhibitors, more than 40,000 registrants, and more than 140 conference sessions on robotics, machine vision, artificial intelligence and other industrial automation topics.

Figure 1: Aamir Paul, president, North America Operations, Schneider Electric gave an Automate 2025 keynote presentation: “Redefining industry: A bold new era for American manufacturing and the opportunities it creates for the American workforce” at Automate 2025 from Association for Advancing Automation (A3). Courtesy: Mark T. Hoske, Control Engineering, WTWH Media

The industrial revolution is now; how is your automation helping?

Paul said labor isn’t going to fill industrial skills gap. There aren’t enough people. Raising wages won’t help because that would be unprofitable in face of global competition. A productivity boom needed to overcome challenges.

Schneider Electric, over 130 years in the U.S., has 21 factories here and has invested more than $1 billion in last few years in the U.S. Paul said 4 in 10 homes are powered by us, and said if you spend 6 hours online you will be in a data center powered by us. Schneider Electric, the most sustainable company in the world as recognized by several awards also has best in class shareholder returns. It’s not true that companies cannot profit from sustainability, Paul said. Sustainability is another vector of waste elimination and it helps the bottom line.

Electricity was the innovation of the 1893 World’s Fair in Chicago, and Tesla, Westinghouse and JP Morgan were there to help. Square D began as Detroit Fuses. The safety switch was developed soon as electrification expanded.

Schneider Electric core industrial technologies now include Asco Power Technologies, OSIsoft, Wonderware, Pro-face, Modicon, ProLeiT, EcoStruxure Foxboro, etap, EcoStruxure Triconex and Aveva.

The system architecture discussion, Aveva and Schneider Electric, cannot separate discussions of energy, automation and data. The 21 U.S. Schneider Electric factories and 1,500 patents help serve 90% of manufacturing sites, 49 of the top 50 chemical producers, 20% of U.S. power generation and all 25 of the top food and beverage consumer packaged goods (CPG) companies, among others, Paul said.

Automation ecosystem issues: Fast versus slow

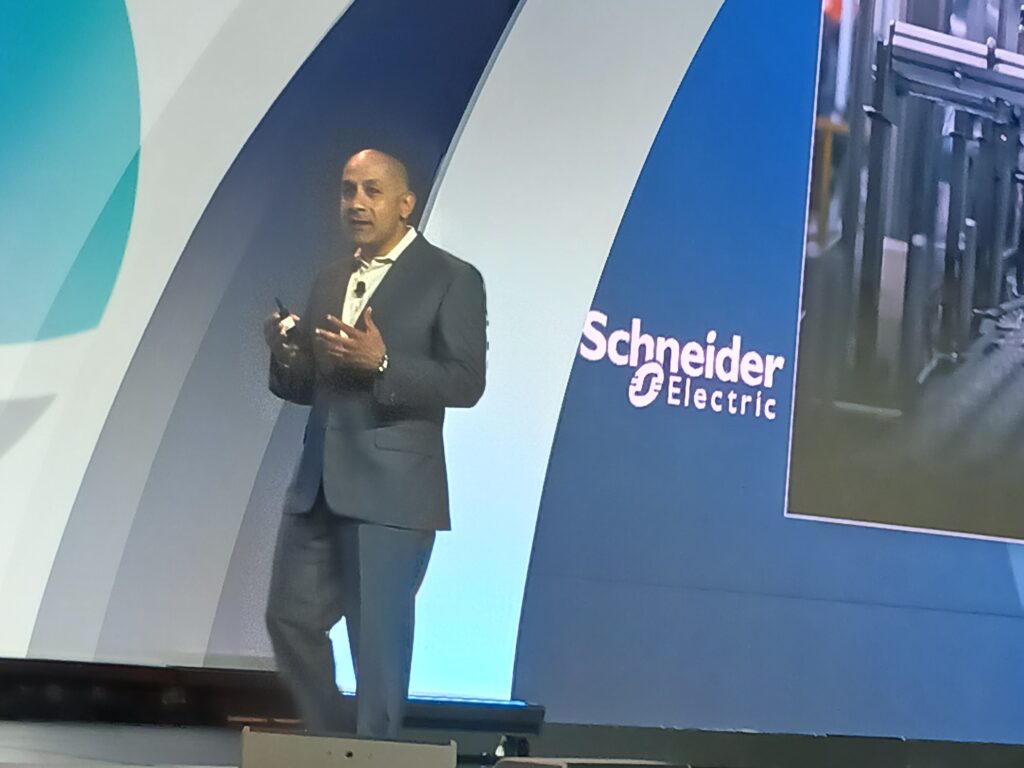

Paul said leadership can help people with accelerating rates of change, including adapting to the increased speed of technology adoption over time (Figure 2). The speed of technology adoption is increasing to levels never imagined. Since the Apple iPhone, almost all major leaps have been software defined. People resist change, first thinking it’s crazy, then dangerous before the change becomes obvious.

Figure 2: Acceleration of change is increasing in the adoption of software-driven technologies explained Aamir Paul, president, North America Operations, Schneider Electric, at Automate 2025. Courtesy: Mark T. Hoske, Control Engineering, WTWH Media

“Not too many years ago, we were not supposed to meet people on internet, and we were told not to get into cars with strangers. Sure, you laugh now, because several successful business models are based on both of those,” Paul said.

Some risk aversion remains in the automation space. “We’ve always done it this way” will not get us the outcomes we need, Paul said. Unlocking greater productivity is defined by software, and barriers need to be overcome with a leadership mindset.

It’s ironic that Blockbuster owned Netflix for a short time. They didn’t see a future in it and sold their interest. You know where that story ends, Paul said. But if you wait until the next answer is obvious, he warned, it will be too late.

Workforce problems: Manufacturing understanding

Surveys recently showed that in the U.S., 80% thought it would be good to return more manufacturing to the U.S., yet only 15% want to work in manufacturing. That’s a problem, Paul said.

Manufacturing will have a 2.1-million employment shortfall by 2030, said Deloitte in 2021. Only 14% of Gen Z respondents would consider industrial work, said Soter Analytics 2023, and 27% of Gen Z wants to work in technology said Soter Analytics 2023.

We have do better job at attracting and retaining, Paul said, because we’re losing talent. If you go to a critical industry, like water and wastewater or an electric utility, ask: “Who do you call when something goes wrong?” Usually there are three 3 or 4 engineers on the list, and most of them are 5 years from retirement. “I’m especially concerned about air traffic controllers right now.”

Paul said there’s a critical need to address and correct the public view of industry. Sponsoring First Robotics (like Schneider Electric does), is one contagious and powerful activity for young people to get excited about technology, he said.

Another concern is the rapid expansion of data centers and impact on utilities. The electrical grid is not designed for the loads required.

Modern manufacturing benefits

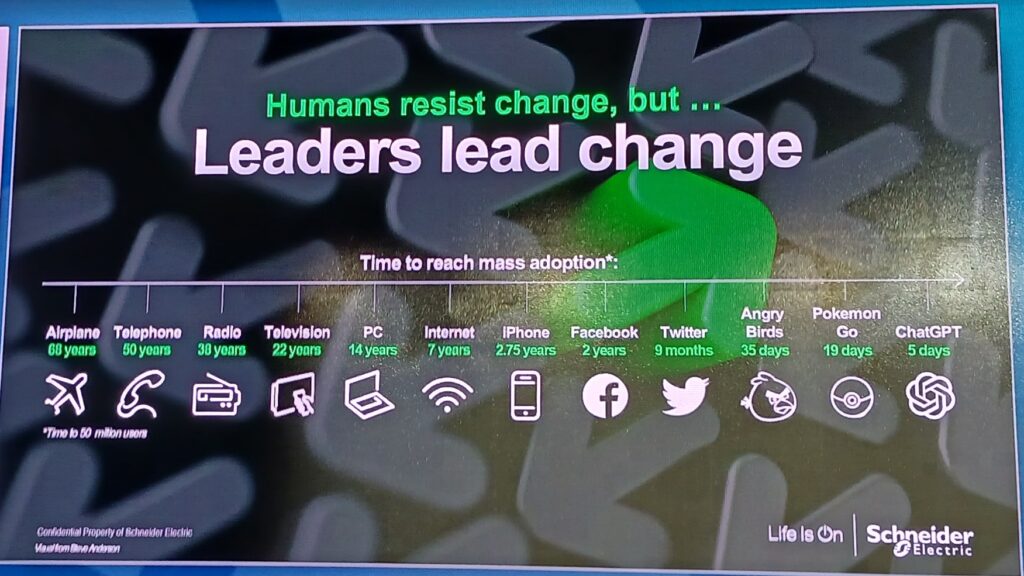

Our Lexington, Kentucky, plant began 66 years ago when the copier, automatic camera and three-point seatbelt were major innovations. Getting people to accept new technology requires proving it; 70% learn by experience, 20% learn in the classroom and 10% learn from benchmark learning.

In the last six years, the plant (Figure 3) strives to get better daily, making more with same group of people in a faster, more agile way. The plant has seen:

26% energy cost savings

20% reduction in mean time to repair

5% reduction in downtime

3.5% year over year energy savings.

Figure 3: Manufacturing advances in Lexington, Kentucky, include include 26% energy cost savings and 20 reduction in mean time to repair said Aamir Paul, president, North America Operations, Schneider Electric, at Automate 2025. Courtesy: Mark T. Hoske, Control Engineering, WTWH Media

Imagine what we could do with a greenfield site, Paul said. The status quo won’t get us with where we need to go.

At Shell’s Alberta facility, we’re implementing open automation with EcoStruxure and etap. What was siloed is now one of most efficient and modern hydrocarbon processing sites, Paul said.

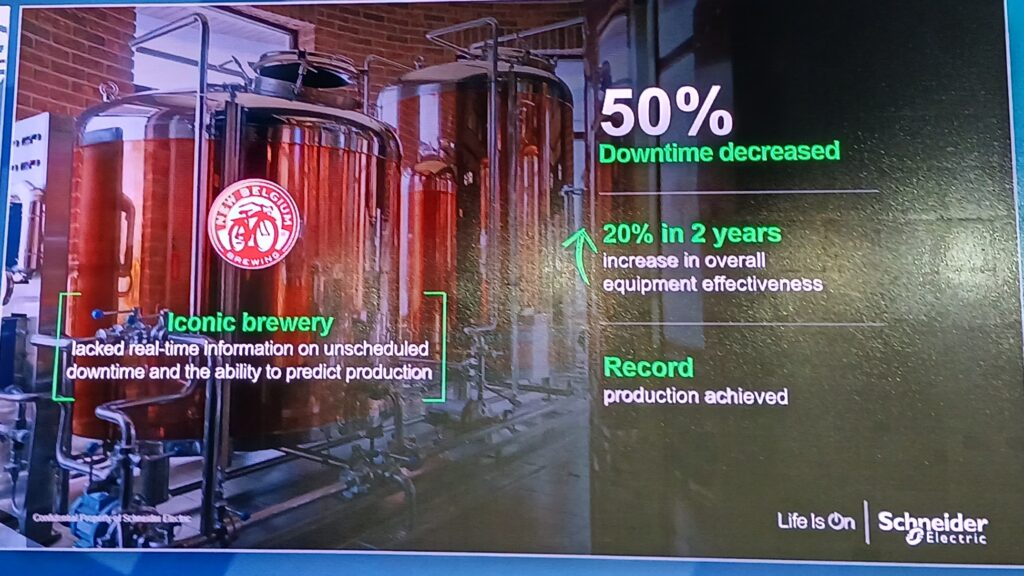

New Belgium Brewing (Figure 4) has had a 50% downtime reduction, and a 20% increase in OEE over two years, resulting in record production for the facility, Paul said.

It’s often a system challenge. Data enables efficiency and resiliency:

6x faster system-level diagnostics

10x faster incident resolutions

20% energy savings

80% reduction in recovery time after a fault.

Figure 4: New Belgium Brewing had a 50% downtime reduction, and a 20% increase in OEE over two years, resulting in record production for the facility, said Aamir Paul, president, North America Operations, Schneider Electric, at Automate 2025. Courtesy: Mark T. Hoske, Control Engineering, WTWH Media

Digital twin advantages

Use of a digital twin allows a site to think differently starting at the design phase; etap enables exploring how to optimize a facility before it opens. It creates digital ready projects. Operating with a digital twin is critical to take full advantage of the design, build, operate and optimize cycle.

Paul said: It’s not just us. I am cheering on other companies working on this. It takes an ecosystem.

Open systems win. Automation has to become a software-defined architecture so facilities can change and update automation faster. Cost of hardware will decrease as it has in the information technologies (IT) sector. What’s the value of a phone or laptop without software? Software drives the intersection of physical AI, automation and data.

For those water and wastewater engineers and other experts leaving in five years, we have to capture their insights, codify that and connect to software to optimize how to operate.

Many companies are working together to unlock 10x benefits of an open, software-defined program.

Invest in people. Operating in highly technical, data-driven environments, it’s not about machines or technology replacing people. Ask if you are investing the right way.

Whether you call it robotics or physical AI, the technology gap no longer has to be a key constraint, though the skills gap is. The future is open.

Mark T. Hoske is editor-in-chief, Control Engineering, WTWH Media, [email protected].

KEYWORDS

Open control systems, software-defined automation, skills gap

CONSIDER THIS

Are you using automation, energy and data to help resolve workforce and other challenges?

ONLINE

Find more coverage by searching “Automate 2025” at www.controleng.com.