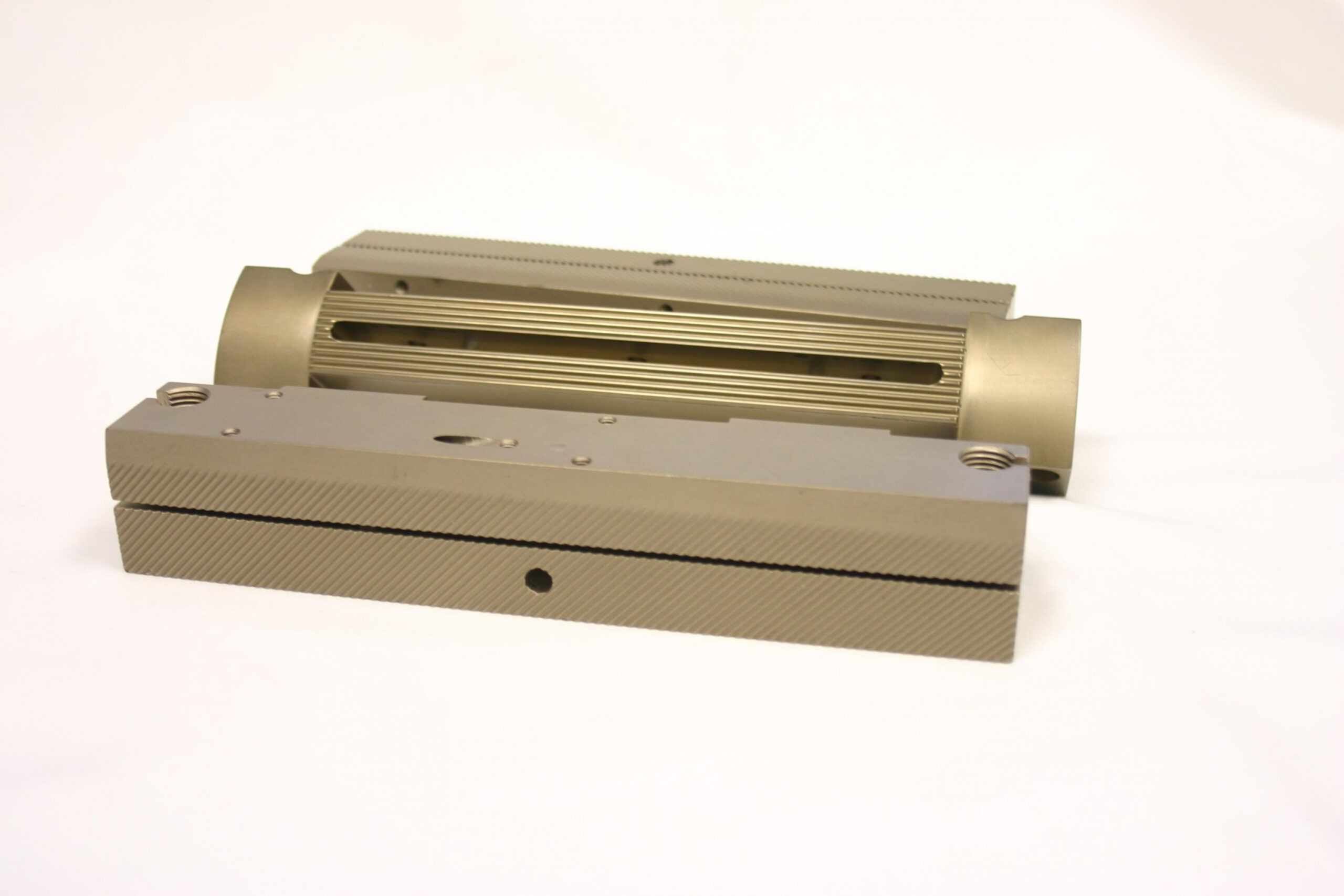

Magnaplate is pleased to announce that its 10K Series surface treatments are free of a broad class of per- and polyfluorinated alkyl substances — also known as PFAS — that are widely used in industrial processes. As regulators take action worldwide, 10K Series coatings give users the peace of mind of being prepared for new and evolving PFAS rules. The 10K Series can be applied to Nedox, Tufram and many other popular Magnaplate coatings to give metal parts the corrosion and wear resistance, hardness or low COF they need. In addition, USDA/FDA-compliant 10K coatings deliver exceptional release properties to parts exposed to extremely high temperatures, ensuring abrasion resistance, easy cleanup and excellent hydrophobic properties.

The 10K Series is available in three variants:

- 10K1. Performs at up to 950°F (510°C)

- 10K2. A water-based coating that withstands up to 950°F (510°C)

- 10K3. Offers the best release properties and performs at up to 850°F (454°C)

There are no PFAS in the Magnaplate anodizing process or the electroless nickel base, so a surface treatment engineered with these select polymers will avoid PFAS-carrying fluorocarbons while protecting metal parts.