The Pepsi/Lipton bottling plant (Ayer, Mass.) recently decided to aim for a 100% increase in throughput. That goal was contingent on how well the control network of its newly installed conveyor system could be integrated with Pepsi/Lipton's existing systems. The plant needed a cost-effective method for interfacing a high-speed palletizer with Pepsi's existing case packing operation.

The Pepsi/Lipton bottling plant (Ayer, Mass.) recently decided to aim for a 100% increase in throughput. That goal was contingent on how well the control network of its newly installed conveyor system could be integrated with Pepsi/Lipton’s existing systems.

The plant needed a cost-effective method for interfacing a high-speed palletizer with Pepsi’s existing case packing operation. This meant integrating new conveyor controls into the company’s 300,000-ft2operation, currently controlled by a PLC. Unfortunately, the existing PLC had no room in its chassis for I/O module expansion, and it was about 150 feet away from the new conveyor’s control panel.

Mike Barone, a partner at Live Automation Inc. (Leominster, Mass.), a control systems integrator, was assigned the project. He had to find a remote I/O system that would be compatible with its installed PLC, as well as allow quick installation; real-time testing and commissioning; and local I/O device forcing capabilities.

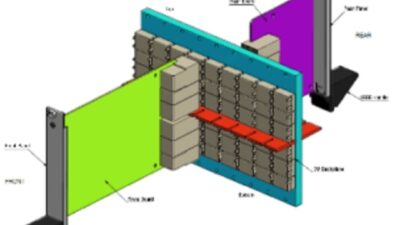

Live Automation, in conjunction with existing integrator, Production Line Control Services (PLCS, Plastow, N.H.), chose to install a “ricos” DeviceNet buscoupler, two 16-point digital input modules, two 16-point digital output modules, and an eight-point I/O module manufactured by Wieland Electric Inc. (Burgaw, N.C.).

“We chose Wieland’s product primarily for its I/O density and onboard I/O forcing capabilities,” says Mr. Barone. “The setup on the DeviceNet protocol was as easy as any I’ve used, and the spring-loaded wire termination points made the electrical installation much faster.”

Simplicity+compatibility = integration

The ricos modules are designed to be compatible with existing PLC and PC-based control systems in a variety of protocols. Because it is a modular system, expanding I/O capabilities is as simple as adding or subtracting modules or programming individual I/O points according to design preferences.

Modules were installed directly at the conveyor location with remote access to the PLC through DeviceNet. This saved the cost and labor of adding additional PLCs at remote locations. The spring-style clamping body provides a high-integrity connection with little effort.

In addition to rapid installation, the ricos module’s “works in a drawer” design allows engineers to quickly pull out its inner workings for repair and replacement, without having to remove wiring. The module is manufactured with a “quick-snap” top for internal component removal, as well as a toggle switch for electrical connection and disconnection.

The existing system used numerous mechanical relays. One I/O module with relay capabilities replaced them. This modification not only saved space in the panel, it allowed on-site troubleshooting and monitoring capabilities previously unavailable.

The modules also feature on-board diagnostics facilitated by a touch-pad system, which allows engineers to perform local diagnostics and commissioning. The local commissioning system allows engineers to “bump” motors and “flag” photoeyes from the buscoupler. These I/O forcing capabilities, along with high I/O wiring density, helped streamline production and reduce downtime.

Live Automation was able to improve system efficiency, as well as enhance throughput, within the Pepsi bottling plant using Wieland’s ricos I/O system with DeviceNet.

For more information, visit www.wieland.com .

| Author Information |

| Gary A. Mintchell, senior editor [email protected] |