Control Engineering offers an hour of webcast instruction with practical advice for “How to select the right controller type for the automation application” on Sept. 25, and this article offers related advice on industrial controller selection.

Industrial controller selection insights

- Explore industrial controller selection advice from system integrators experts, also instructors in a September Control Engineering webcast.

- Understand physical requirements for an industrial controller and that you may not get the best controller, but the best controller for the application.

- See the webcast for more advice: Register for the Control Engineering webcast, “How to select the right controller type for the automation application,” archived until Sept. 25, 2026.

Get advice on “How to select the right controller type for the automation application” from Control Engineering in a Sept. 25 webcast (archived for a year); webcast instructors provide controller selection advice below. The instructors (Figure 1) are:

- Jon Breen, founder/owner, Breen Machine Automation Service LLC

- Vinoth Upendra Janardhahan (“Vinoth”), automation engineer, CDM Smith.

Moderator for the webcast is Mark T. Hoske, editor-in-chief, Control Engineering.

Industrial controller selection advice

“Automation and controls applications are growing in numbers and breadth across industries, and it’s critical to ensure the selected and applied automation controllers are fit for purpose,” according to the webcast description. It continues: “For most applications, more than one controller type may be suitable. How should you choose from among programmable logic controllers (PLCs), programmable automation controllers (PACs), industrial PCs, embedded controllers, edge devices, human-machine interfaces (HMIs) and hybrid controllers that may be integrated with or combined in computers, drives, robotics, vision and input/output (I/O) devices and systems? Should you mix and match vendors or stay with one ecosystem? Way beyond initial cost, criteria may include environment speed, operating system, cybersecurity, standards, interoperability, lifecycle, communications, training and more.”

Perhaps not the best controller, but the best for the application

“I’ll say up front that you’ll never have the time to select the ‘best’ controller,” Breen explained in his notes for the webcast (Figure 2). “As with most engineering applications, we’re going to lean on rules of thumb and experience to quickly narrow the list of options to something that will work reliably for a reasonable cost (good not best).”

By focusing on specific industrial controller application needs, it allows the vague terms related to industrial controllers be vague, Breen noted.

“The first thing I ask when I’m looking at a new application is about brand,” Breen said. It’s common to standardize on a single brand for a lot of good reasons – fewer software licenses, fewer spare parts, less training, etcetera, but this can also come with some risks.”

Having one brand of industrial controller for an application, Breen said, “also dramatically simplifies the process of selecting a controller because that brand will usually have three lines to choose from – small, medium and large. But this also comes with some tradeoffs.

“If that brand doesn’t support certain functions, you just can’t have them. And if that brand finds itself preferred for many customers, it’ll raise prices without offering more features.”

Breen called it a “consumer-defined monopoly,” noting that with the supply chain issues over the pandemic, many customers were “forced to consider other options, and some of them were very happy with what they found.”

Breen’s not locked into any one supplier forever, though. “I do encourage teams to standardize, but to keep an open mind and deliberately reconsider every few years. The controller selection often has broad-reaching implications for the rest of the control system.”

How to define industrial controller application requirements

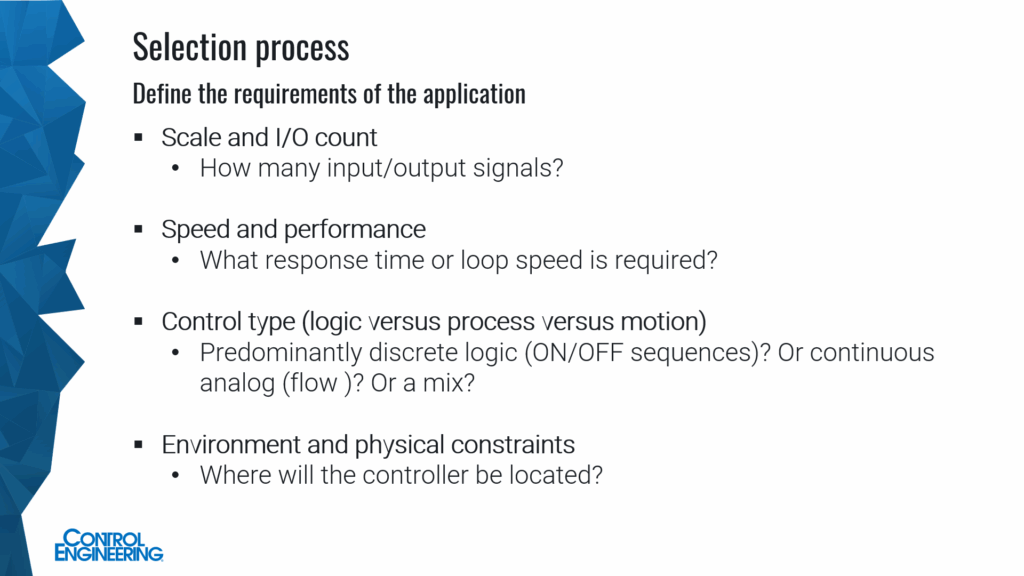

Vinoth, in preparing for the webcast, discussed four steps to define the requirements of the industrial controller application (Figure 3).

1. Scale: Controllers have limits on how many I/O modules or points they can handle. For example, a small PLC might support a few dozen I/Os; meanwhile a large PAC or DCS can scale to thousands with distributed I/O racks. If you underestimate I/O count, you might select something that runs out of capacity, forcing you to add another controller mid-project. It’s prudent to not only count current I/O but also add an allowance for future expansion.

2. Speed and performance: If your process is time-critical, say we’re dealing with a high-speed packaging line that needs millisecond decisions, you need a controller known for fast cycle times (PLC might cycle in 5-10 ms, which is fine, but a DCS might be 100 ms, which could be too slow in that case). Also, if you have a lot of interlocking and motion, a PAC might be required. On the other hand, if it’s a slow process (like environmental temperature control where things change over minutes), you don’t need to pay for a premium Controller, rather a robust, steady controller is more important.

3. Type of control. Discrete-heavy projects suit PLCs, analog process loops suit DCS or PACs with strong PID capability. Motion needs either a PAC with motion modules or dedicated motion controllers. Safety adds another layer – emergency shutdowns may require safety-rated PLCs or redundant controllers.

4. Environment: It’s one thing to see a controller work in a lab, or on a plant floor next to a furnace or out at a remote well in the desert. Temperature range, humidity, corrosive atmosphere, electrical noise – all these factors can rule out some options. PLCs are generally built tough, but industrial PCs need hardened designs. Vibration also is a factor, for example, controllers on skid-mounted equipment or near high electro-magnetic interference (EMI, from large motors, for instance) need shock resistance. Power is another consideration – some remote controllers can run on 24 VDC from a solar panel, while others need clean AC power. Physical space: if you only have a tiny junction box available, you might need a micro-PLC or embedded controller; if you have a full control room, a rack system is okay.

So, tailor the hardware based on physical conditions, Vinoth added.

Mark T. Hoske is editor-in-chief, Control Engineering, WTWH Media, [email protected].

Keywords

Industrial controller selection, PLC selection

Consider This

Are you getting all you need from your industrial controllers, or are you past-due for upgrades?

Online

Register for the Control Engineering webcast, “How to select the right controller type for the automation application,” archived until Sept. 25, 2026, here:

https://event.on24.com/wcc/r/5060437/B8E7A107A08112332D0BBF3E982F1C5F