Perhaps the most common computer connector you will find today is the USB port that adorns every type of computer hardware, including printers, keyboards, cell phones, cameras, flash drives, games, and an increasing amount of industrial equipment. USB stands for universal serial bus, and universal it is, with more than 2 billion devices using the connectors and communication protocol.

Perhaps the most common computer connector you will find today is the USB port that adorns every type of computer hardware, including printers, keyboards, cell phones, cameras, flash drives, games, and an increasing amount of industrial equipment.

USB stands for universal serial bus , and universal it is, with more than 2 billion devices using the connectors and communication protocol. The current version, USB 2.0, from April 2000, specifies how data is sent up and down the cable.

The standard USB cable has four conductors: two carry power (5 V dc, 500 mA max.) and two, as a twisted pair, carry data. The protocol can support a network of up to 127 devices through one port on the host by using USB hubs. USB cables have a maximum length of 5 m and can be extended by using daisy-chained hubs. The host device, a computer typically, communicates with devices connected directly or via the network. The host communicates via one of three protocols within USB 2.0, depending on the nature of the device and its communication needs:

-

Interrupt—Small amounts of data over an extended time period, as does a computer keyboard.

-

Bulk — A large block of data all at once, such as a printer or digital camera download. Data moves in 64-byte chunks and is verified.

-

Isochronous—Communicates streaming data in real time, audio, video, etc., where there is no error correction.

| Agilent U2000 Series of power sensors from Agilent Technologies Inc. are said to offer fast and easy setup with plug-and-play USB connectivity. www.agilent.com |

When a host finds a device on the network, either after powering up or when the device is inserted hot, it assigns an address and chooses the appropriate communication protocol. All devices do not communicate at the highest speed. Some that transfer less data use 12 or 1.5 Mbps when that is adequate.

In industrial applications, USB is used in the same types of applications as older serial communication platforms, such as RS-232 and RS-485. While USB has largely displaced older serial protocols in the IT world, for industrial applications the progress is mixed.

“We are seeing more USB on devices,” says Ed Nabrotzky, general manager, Woodhead Industrial Communications. “It’s the coming de facto configuration.” He attributes this to USB’s ease of hooking up, auto recognition, and connecting hot. Technicians prefer USB to more cumbersome RS-232 techniques, however the biggest limitation may be the short cable length.

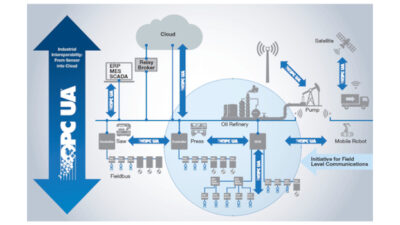

Others aren’t so ready to change. “For process automation systems, we see limited application of USB communication,” says Todd Stauffer, process automation marketing manager, Siemens Energy & Automation Inc. “USB is used primarily for communicating with printers, although Ethernet is a more prevalent choice, particularly for networked architectures. Serial communication using RS-232 is still a mainstay for process automation, but as PC technology continues to advance, it is becoming harder to find PCs with built-in serial ports, particularly those that might be used to perform configuration tasks.” There are PC adapters which can be plugged into a PC’s USB port allowing it to access the controller’s (MPI/DP) configuration ports if required.

Like Ethernet, USB began as an IT product and has been adapted to industrial uses. Hardened connectors and cabling are available from various sources that permit locking. Some manufacturers use the same locking devices that surround Ethernet connectors to protect USB connectors. Locking methods can be proprietary, however, so check for compatibility.

| Author Information |

| Peter Welander is process industries editor. Reach him at [email protected] . |