In today's controls marketplace, customers are demanding better products, faster system implementation and lower costs. Even as customers are asking for these, control systems are becoming more complex and project timelines are shrinking. Controls suppliers and system integrators, meanwhile, must maintain profitability.

In today’s controls marketplace, customers are demanding better products, faster system implementation and lower costs. Even as customers are asking for these, control systems are becoming more complex and project timelines are shrinking. Controls suppliers and system integrators, meanwhile, must maintain profitability. Faster system construction and easier wiring is paramount for ensuring that everybody wins.

To help construct industrial control cabinets more quickly and deliver them at lower costs, integrators are beginning to adopt the Lean Manufacturing process. This approach can be taken with the control cabinet as well by using a “lean” design. The fewer products used in a control system, the faster it can be commissioned. In turn, this makes future maintenance easier for the end user, thus becoming an additional selling point for the integrator.

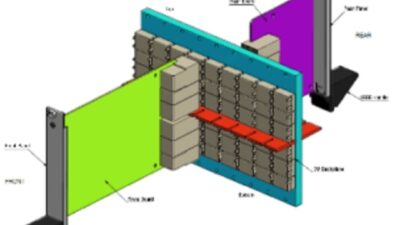

To realize the potential of a lean design principle with industrial control cabinets, let’s look at a standard 32-channel output card. On the typical 32-channel output card, there are 40 terminals—32 terminals for the I/O connections and eight for power and return. To terminate these points, the installer must connect not only the 40 connections on the card, but also the 40 connections on the field side of the control. This can consume impressive amounts of wire, ferrules, wire ties and wire labels, not to mention valuable time. By implementing a systems-cabling approach, a single cable and termination module cuts the wiring time dramatically, while eliminating the need for ferrules, raw wire, and multiple wire labels.

Fewer parts required

Not only does this approach make the control wiring implementation faster and easier, it also requires fewer parts and individual line items. The result is a reduction in control wiring that requires less cutting and trimming of wire, as well as a reduction in labeling and mistakes. A systems-cabling approach will also reduce the amount of time in the design process by reducing wire lists, pages of wiring diagrams, and complex cabinet layout details.

These few short points show how the systems-cabling approach can help reduce the overall waste associated with each cabinet job, and reduce the time required to commission a cabinet.

The use of a plug-and-play cabling system in the control cabinet may also encourage the use of low voltage I/O in the cabinet, which is another source of space and money savings. Eliminating the high voltage I/O from the controller, the customer can save money using less expensive 24 V dc I/O. This makes the overall PLC rack smaller, through the use of higher density cards, and promotes safer cabinet design as well. By limiting high-voltage wiring to the incoming power circuit and the field device wiring only, the technician is also safer when working on the cabinet.

DIN-rail-mounted relay modules help move the high-voltage I/O to a lower location in the cabinet, making relay maintenance easier. It is less expensive to replace a single pluggable relay than to replace an entire relay card.

Skeptics take note

Despite the compelling case for the systems-cabling approach, many control system contractors are still skeptical about switching to a systems-cabling approach. This is primarily due to the change in wiring practices that are used, and their effect on UL and NEC standards. To help reduce this concern, let’s examine the product set that is used in traditional control systems, and compare it to the systems-cabling approach.

Typically, control system integrators and panel shops use 18AWG wire to connect to I/O cards in control cabinets. According to NFPA 79 section 13.6.4, “Conductors for electronic programmable control input/output and static control shall not be smaller than permitted in (1) and (2).” Item (1) has an exception stating “conductors 30AWG or larger shall be permitted if part of a jacketed, multi-conductor cable assembly or cord.” Item (2) also has an exception that states “conductors 30AWG or larger shall be permitted for jumpers and special wiring applications.”

Now, if we take a look at the UL standard for industrial machinery in section 66.9.2, we find: “Control circuit conductors shall not be smaller than No. 18AWG.” However, this UL standard also has an exception. “Control circuit conductors for programmable input/output and static control wiring are able to be sized No. 18-30AWG.”

Both the NEC and UL standards above say that it is acceptable to use 26AWG multi-conductor cables in PLC and DCS wiring applications. This debunks the myth that all control circuit wiring must be 18AWG. This also proves another point: Most people use 18AWG discrete wire for I/O control because it is an accepted industry practice. Taking the stance of “this is the way it has always been done” prevents system integrators and panel builders from accepting newer technology to help improve their bottom line and better serve their end user customers. By using a systems-cabling approach, a control system is more reliable and easier to maintain years down the road.

| Author Information |

| Ken Allwine is product lead marketing specialist for Phoenix Contact’s Interface power supplies, relays, and cabling. |