Recycling center upgrades baling machine to an outdoor-sunlight readable human-machine (HMI). Larger screens decreased number for used from six to three.

Learning Objectives

- Rugged HMI has wide temperature range.

- HMI includes communications, programming support.

- Retrofit system integration of HMI can improve machine application.

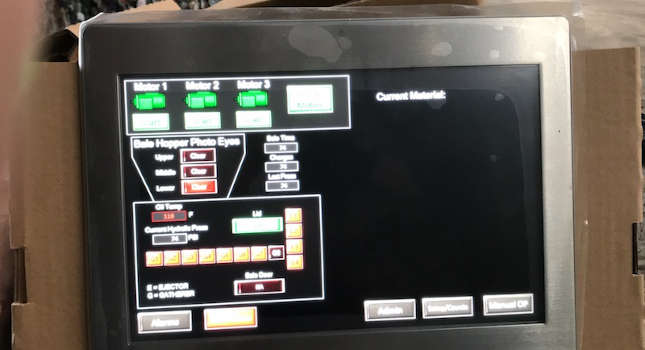

A recycling center uses a human-machine interface (HMI) in its machines that controls the function of collapsing the boxes and wrapping the cardboard for delivery and distribution to multiple locations. The facility used an older HMI that had process faults, screen damage and poor visibility in direct sunlight. The original screen response was sluggish in cold temperatures, the screen scratched easily and the unit started failing 5 years after installation.

The customer also needed an HMI that could work with their current programmable logic controller (PLC), provide flexibility and had a longer life expectancy in a potentially harsh environment.

Rugged HMI has wide temperature range

An outdoor-rated HMI with screen development software has extensive connectivity options that allow for integration with the customer’s existing control system. The sunlight-readable 12-in. display offered improved visibility for easy-to-read screens and its stainless-steel bezel provides outdoor ready specifications for harsh environments.

By redeveloping the screens within the new software using a larger screen size, they were able to reduce the number of screens needed from six to three, simplifying the process and saving time and money for the customer. Since the display is larger, creating a larger panel cut out is simple and allowed for a quick replacement. Beyond the screen size, having a sunlight readable solution provided better visibility and accessibility for users from a distance. This unit also sustains a wide range of temperatures from -30 to 70 °C, which is an upgrade from the typical 0 to 55 °C for an HMI unit. The outdoor HMI also uses a tempered glass screen.

HMI includes communications, programming support

The HMI was retrofitted for a semi-outdoor environment where it would experience a wide range of temperatures. The unit has more processing power than the application needs, and serial DF1 communications are built in. Implementation is simple, and there are numerous other target applications where the technology could be used in the future.

The solution was economical and included a display, box module, and programming support. The extensive temperature range, vibration specifications and ultraviolet (UV) resistance for a high-quality solution at a much lower cost. Screens also can be used in several places outside of the brand-labeled screens and remotely updated.

The project distributor was Grant Industrial, and the system integrator was Wicked Edge Automation.

Janelle Morris is Pro-face America marketing communication manager. Robert Springer is a system integrator at Wicked Edge Automation. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media and Technology, [email protected].

KEYWORDS: Human-machine interface, HMI, outdoor HMI

CONSIDER THIS

What new HMI technologies can help your machines operate more effectively?