The benefits of cabinet-free machines are attainable for original equipment manufacturers (OEMs) and end users with reasonable goals and a phased approach. Three levels to this phased approach are highlighted.

Learning Objectives

- Understand the advantages of cabinet-free machine design.

- Explore three levels of implementation, from simply adding functionality in brownfield systems to completely cabinet-free designs in greenfield applications.

- Recognize how to select a future-proof, scalable automation platform that will preserve your intellectual property (IP) in the transition to cabinet-free machine design.

Enclosure insights

- Transitioning to cabinet-free machine design mirrors a runner’s journey, starting small with distributed I/O, then advancing to machine-mountable controls before aiming for complete cabinet-free solutions.

- Cabinet-free systems reduce costs, streamline wiring, and minimize footprint requirements, offering modular options that enhance installation, support, and maintenance processes for manufacturers and end users.

- While cabinet-free design presents significant advantages, users should strategically assess their needs, embracing scalable automation platforms and open communication protocols to future-proof their systems amidst ongoing technological advancements.

Runners who want to do a marathon don’t just show up the morning of with worn-out sneakers and good intentions. Runners follow training regimens. They tackle progressively longer races—a 5K, 10-mile and half marathon. This way, they’re prepared for success when the big event arrives.

Designing toward a cabinet-free machine is similar. New machine control technologies are helping leading-edge systems begin to ditch the enclosures previously needed to protect power supplies, input/output (I/O), networking, human-machine interface (HMI), control and other equipment from harsh production environments. Users who want to reap the benefits of eliminating electrical cabinets can start by taking smaller steps first.

There are many advantages for machine builder original equipment manufacturers (OEMs) and equipment end users alike. A complete machine-mounted control system can reduce overall costs. Beyond getting rid of the enclosure itself, the machine no longer needs fans, filtration systems, cooling equipment and the associated power to run it all. With standard connectors on all components, users reduce wiring time, eliminate wiring errors and cut documentation.

Manufacturers can reduce footprint requirements to pack more machinery into the same square footage. And emerging modular options for cabinet-free machine control help simplify everything from wiring and installation to support and spare parts inventories.

But let’s not get ahead of ourselves. To see how to get from a cabinet-dependent design to a cabinet-free one, it’s important to understand the various steps it’ll take to get there.

Level 1: Distributed I/O for data acquisition and more

So what’s the 5K run in this scenario? That would be adding functionality without expanding the control cabinet.

The place to start is adding remote I/O and IP65/67-rated machine controllers that don’t require the protection of an enclosure. While ruggedized I/O blocks in IP67 or even IP69K are not exactly new, the strategic application of these technologies has offered significant advances in many applications. These devices gather more data in more places, whether that’s for communication, acquiring signals from sensors, integrated functional safety and more. By distributing the I/O closer to the end devices, users will cut back cabling runs, as well.

Industrial PC (IPC) solutions that can be installed in the field, however, offer new possibilities. Leveraging these technologies doesn’t necessarily mean using the control hardware to run the machine. The IPC could handle control logic for a specific machine module that can be unplugged and moved around the factory floor.

In brownfield applications, one of these IPCs could be added as an IoT gateway or edge computing device. Flexible mounting options make it easy to physically attach the controller where it makes the most sense. This eliminates the need to find space in the cabinet and worrying about the additional heat source, along with the need to run multiple cables all the way back to the cabinet. With a port for EtherCAT P, which combines power and communication in a standard 4-wire cable, the controller can support the addition of I/O blocks for data acquisition or special functions.

Equipped with an analytics software package, the IPC could perform some preprocessing of data, then send important metrics to the enterprise or cloud level using a cellular or Wi-Fi transmitter. This is a great option if older equipment still meets throughput and quality requirements, but it needs to provide data to measure machine health or energy efficiency.

Level 2: Machine-mountable control and distributed motion control

The next level is shrinking control cabinet requirements for new machines. Technologies to build cabinet-free machines are continuing to evolve. As a result, many engineers are taking a wait and see approach. However, numerous machine-mountable devices are already available to minimize the need for large, protective enclosures.

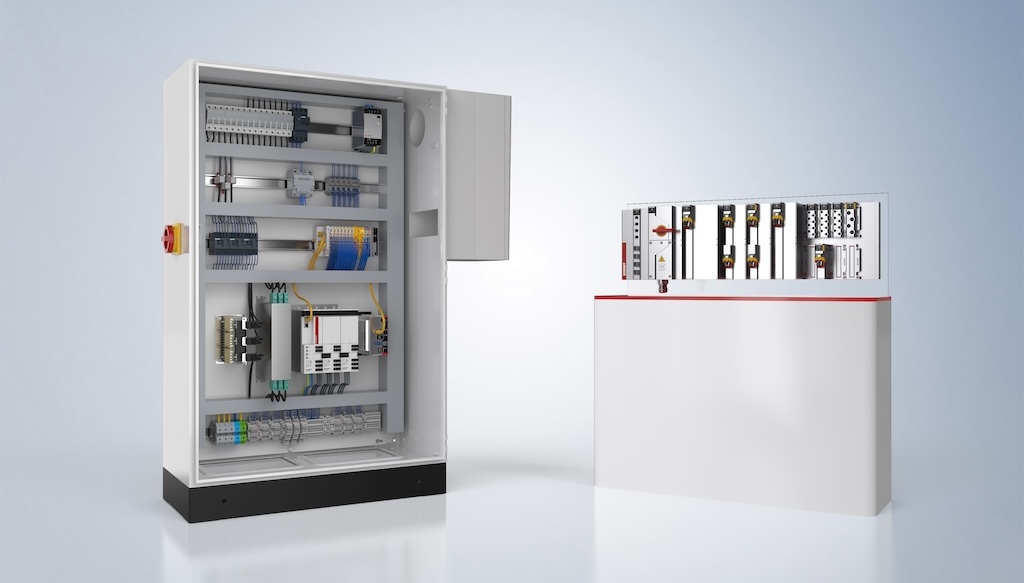

Employing a dual- or quad-core cabinetless IPC as the main machine controller and using servomotors with integrated drives makes this possible. Some electronics – power supplies, fuses, contactors, etc. – may need to remain in an enclosure, but with these cabinet-free options, the necessary footprint shrinks dramatically.

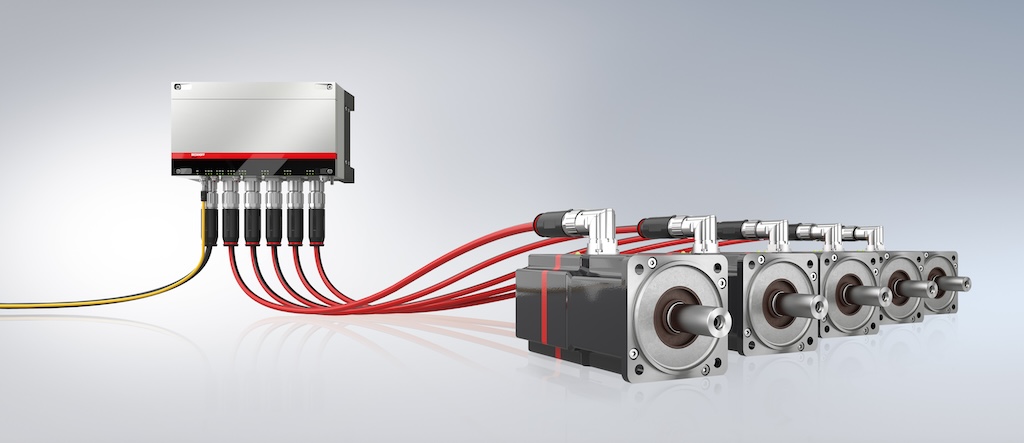

We’ve seen numerous systems take this route. Typically, they use an IP65/67 IPC or a fully enclosed panel PC, which combine the machine control CPU with rugged HMI hardware. Building on the remote I/O solutions and EtherCAT P communication, a distributed servo drive system allows the machine builder to incorporate dynamic motion control without needing to reserve a large section of the electrical cabinet for separate drives.

These distributed servo drive solutions integrate the amplifier onto the back of the motor. An IP67 distribution module streamlines daisy-chaining for systems with advanced motion requirements. The distribution module can also connect via EtherCAT P to other sensors, actuators and more, enabling a complete machine with reduced requirements for electrical enclosures.

In addition to stationary machines in packaging, intralogistics, assembly and other industries, these types of solutions are ideal for mobile robotics. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) both have very compact enclosures. Including a controller on the exterior or at least in a space that’s partially exposed to harsh production environments offers a significant level of flexibility.

In either case, the PC-based controller could also consolidate several functions that usually require separate hardware, for example, programmable logic controller (PLC), safety, machine vision and navigation.

This level of cabinet-free control could be a stopping point — or it could be a step forward into the next challenge. Just like a runner working up to that big race, the cabinet-free machine controller, I/O and servo solutions should build upon proven technologies.

Level 3: Complete cabinet-free control

The final level is ditching the cabinet entirely. The technologies required to make this happen remain a work in progress, since not every type of device needed for control and automation is available in IP65 or higher.

Technologies are entering the market that allow for a modular design of cabinet-free control. With scalable baseplates, these systems have IPCs, drives, I/O, functional safety and more as pluggable building blocks. They can be attached and secured with set screws quickly, without requiring hours of a cabinet building specialist’s time.

In fact, estimates show control system installation processes that would regularly require 24 hours or more could now be completed in just one hour using pluggable automation components in a machine-mounted platform.

Space savings also grow with this completely cabinet-free approach. Distributing the control components across the machine, rather than concentrating them in a single enclosure with numerous wires snaking back, can lead to significant footprint reductions.

Using a modular system built on scalable baseplates will offer a range of benefits including:

-

Reducing overall machine footprint by up to 70%.

-

Slashing the number of control components required by a factor of 10.

-

Consolidating documentation by as much as 80%.

-

Eliminating costly wiring errors through pluggable devices.

-

Removing numerous points of failure.

-

Accelerating time to market through rapid commissioning.

The fully machine-mounted control platform’s footprint and complexity reductions facilitate better collaboration between departments. For example, engineers will no longer have to design special installation spaces and brackets for the system. More modular, pluggable designs will also reduce the need to disassemble completed machines before transporting them to end user facilities.

For equipment end users, the advantages will include improved operating reliability, reduced routine maintenance requirements and simplified troubleshooting and repair, if needed. For example, some will feature diagnostics viewable on smartphones via Bluetooth, unique serial numbers in the form of DataMatrix codes on each module and the usual status LEDs. Technicians can scan these codes using a smartphone app to retrieve diagnostic data from the controller and corresponding function module.

EtherCAT communication can help providing comprehensive, system-wide diagnostics. The industrial Ethernet system also supports hot swap capabilities, which makes replacing modules, if needed, as straightforward and quick as possible.

Get in the running for cabinet-free enclosure machine design

With all of these advantages, it’s no surprise that engineers are engaged at all levels. However, it does require some reconsideration of how electrical and mechanical systems work together. Some find that level two with machine-mountable control offers all the advantages they currently need, and their end user customers aren’t asking for a more intensive redesign at this time.

Whatever level is right, it’s important to consider the options carefully. A flexible, scalable automation platform will allow users to leverage existing software platform and design, whether it’s adding an IP65/67 IPC or switching to an entirely cabinet-free machine control solution.

Users also will want to make sure the leading-edge systems support open communication protocols. After all, it’s highly likely they’ll need to communicate to legacy equipment or incorporate small, remote enclosures for components that aren’t yet available in cabinet-free design.

In these cases, users may find that some vendors also have approached cabinet-free design as a marathon, not a sprint. Machine-mountable technologies have continued to build upon each other to get closer to the finish line.

Machine builders and system integrators can begin deploying more extensive cabinet-free solutions — standalone IPCs, I/O and drive technology — to claim a head start when cabinet-free automation systems soon emerge as the main event.

Eric Reiner, IPC and MX-System product manager, Beckhoff Automation LLC. Edited by Chris Vavra, web content manager, CFE Media and Technology, [email protected].

MORE ANSWERS

Keywords: I/O systems, machine design

ONLINE

For more information:

CONSIDER THIS

What considerations do you have for a cabinet-free enclosure?