Understanding proportional gain and integral time’s functions in control loop tuning values and how they work together is important.

Learning Objectives

- Understanding proportional gain and integral time is critical for control loop tuning.

- Control loop tuning processes can be classified as accumulating or non-accumulating,

- Integral time is relative to accumulation and proportional gain is relative to size in control loop tuning.

To determine initial control loop tuning values, users must first look at what type of process we are dealing with and understand what the primary tuning constants P (proportional gain) and I (integral time) do. Processes can be classified as accumulating or non-accumulating.

- Accumulating – Processes where material or energy are accumulated or held. Levels are accumulating because they hold volume or mass. Vapor pressures can be accumulating as they accumulate gas. Some temperatures are accumulating because they hold heat capacity.

- Non-accumulating – Flows, hydraulic pressures, and temperature due to combustion.

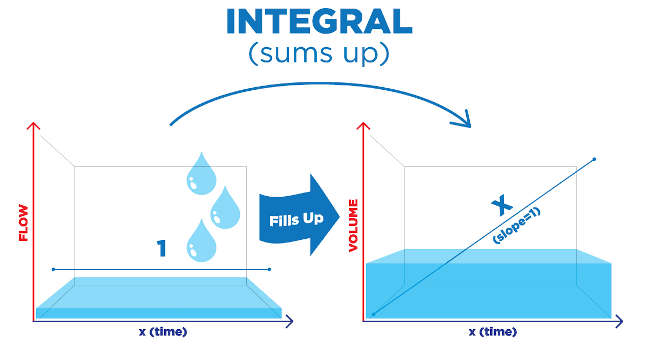

Why is this important? Integral time is based on the time it takes a process to accumulate (see figure 1). For example, if it takes 5 minutes to fill a tank halfway at full feed, the integral time will be somewhere in the neighborhood of 5 minutes. Conversely, the time it takes for a change in valve position to reach the flowmeter is a matter of seconds. This would be a good start for the integral time for the flow.

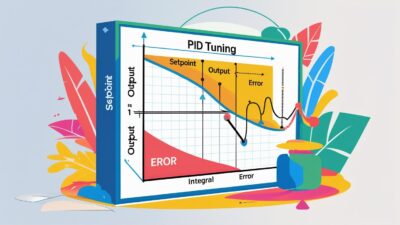

Proportional and integral fundamentals for control loop tuning

Let’s look at this general rule at play. The integral time (in time per repeat) is relative to the accumulation time. A large time to accumulate means a large integral time; conversely, a short accumulation time means a small integral time. Once we get an integral starting point, we can work on proportional gain.

Proportional gain is relative to size. For example, a large tank could have a very large proportional gain and stay in control. That might mean, for instance, a value of 20 for a very large vessel, where a small tank could only tolerate a smaller proportional, say 2. When dealing with proportion, keep in mind how far we want the valve to travel based on the error (difference between setpoint and measurement). Since users don’t want the tank to run empty or overflow and the integral time is rather long, the proportional should be a value of 1 or greater.

Since the process for a flow is small compared to a level, the proportional gain should be small, most likely less than 1. Pressures can be small if users are trying to control the hydraulic pressure in a line, or large if they are controlling the vapor pressure of a large vessel. Larger processes are often accumulating while smaller ones are non-accumulating, which means process size and proportional are relative.

Derivative is something users want to avoid unless the process has excursions, such as a reactor temperature that has a rapid rise and fall due to reactivity. In this case, users are looking at the rate of change and trying to mirror that with the derivative time.

These few simple rules can help get a control loop into a position where users can fine tune it to get the kind of recovery curve desired from process upsets. Keeping in mind integral time is relative to accumulation and proportional is relative to size will help get the loop tuning process started.

Rocky Chambers is a control systems specialist at Maverick Technologies, a CFE Media content partner. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, [email protected].

MORE ANSWERS

Keywords: control loop tuning, process control

Understanding proportional gain and integral time is critical for control loop tuning.

Control loop tuning processes can be classified as accumulating or non-accumulating,

Integral time is relative to accumulation and proportional gain is relative to size in control loop tuning.

CONSIDER THIS

What additional fundamentals should users consider when it comes to control loop tuning?