Automate 2024 focused on bringing people and technologies together and making automation better and more focused on process and results.

Automation insights

- Automate 2024 emphasized improving automation using IIoT, AI, and ML to make better decisions and address workforce shortages. However, automation alone isn’t a complete solution.

- Three essentials for successful innovation were highlighted: Having the right strategy, technology and people.

- Safety and cybersecurity remain major focuses and companies can find the right solutions to their problems if they remain vigilant and know the standards designed to keep their workers and their processes safe.

The last time Automate was in Chicago in 2019, things were quite different. Automate was at McCormick back then, but they were sharing the event with ProMat. The COVID-19 pandemic was a year away and the next Automate was planned in 2021 for Detroit as its own event for the first time.

It’s been quite a journey since then. Automate did not return until 2022 in Detroit and was a rousing success and became an annual, rather than biennial, event. The show’s return to Chicago was a nice homecoming in many ways and, to a degree, not much had changed since then. True, there were more robots than ever on the floor and the themes of artificial intelligence (AI), machine learning (ML) and the industrial Internet of Things (IIoT) weren’t quite as dominant as they are now.

While making automation better has always been a major theme of Automate, it seemed to be more pronounced than usual this year. Companies are still struggling to find people to fill jobs and automation can help bridge those gaps. They also face challenges leveraging the IIoT, AI and ML and using all the information to make better decisions.

However, it only goes so far. Automation is a great tool to improve manufacturing and it will always have a role, but it’s not a magic bullet.

Enabling successful innovation in automation

In his presentation “Transforming EV Manufacturing with Advanced Automation,” Paul Stephens from Ford Motor Company said there are three things needed for successful innovation: Have the right strategy, technology and the right people and culture.

Industry 4.0 was at the heart of their Blue Oval City project, which encompassed many technologies and concepts. They used Industry 4.0 to take in what was available, acknowledged their challenges and matched technologies to address them. All these concepts are coming together and bringing better insights and improving the overall performance.

Connectivity is more important than ever and customers like networking their systems so everything is connected.

“It’s easier to analyze or even just get errors faster — or perhaps knowing already, such as predictive maintenance,” said Michl Abt, senior service and application engineer, SEW Eurodrive. “I think this is the trend, people want to know what’s going on. And they use their computer anyway, so why not get the data to improve production?”

The more data users receive, the better their insights will be and the better they can do their jobs in the short- and long-term.

Bridging the islands of automation

Melonee Wise, chief product officer of Agility Robotics, discussed islands of automation during her presentation “The Next Frontier of Automation: Mobile Manipulation Robots (Humanoid Robots),” which seemed to be an apt and appropriate description for the challenge manufacturers face regardless of the industry.

Manufacturing and other industries have spent more money on robots and automation, but the people part of the equation remains a sore point.

She referenced humanoid robots, or mobile manipulator robots (MMRs) as a solution to handle some of the dull and dirty tasks between the different automation points and serve as a bridge.

Robotics, Wise said, have evolved. “It has created highly specialized automation that has driven us to automate these workspaces.”

Integrating technologies and concepts for better results, flexibility

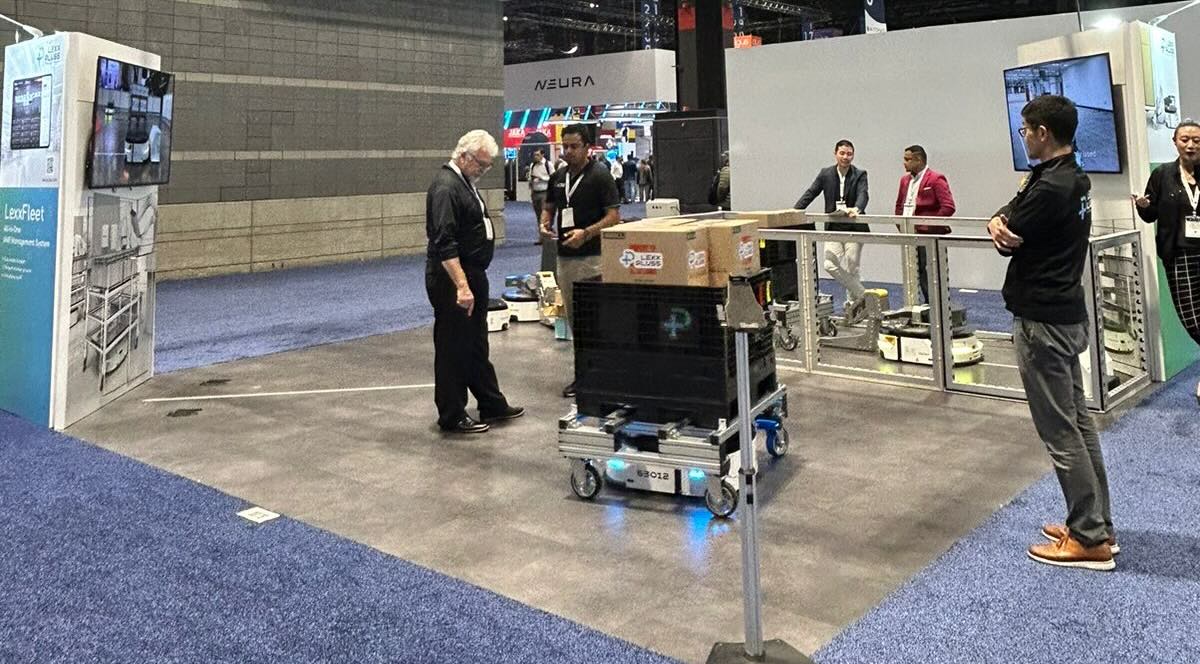

It’s fascinating to go on a tradeshow floor and see robots running through the floor unobstructed and doing their business the way a person would. It’s a little jarring at first, because the robot seems unaware of what’s happening, but that’s not the case. These autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) see as well as we do.

Consider, for example, LexxPluss, which launched their scalable and interoperable mobile conveying solutions. Their four automation solutions are designed to help manufacturers to realize the autonomy of next-generation manufacturing plants and logistics centers, providing the flexibility and interoperability needed in a dynamic modern manufacturing environment. Multiple sensors, including LiDAR sensors, ultrasonic sensors and depth cameras, protect the safety of workers and objects being transported.

Systems need to be flexible and adept in an environment that often changes from second to second. Everything must be safe, but efficient, to meet key performance indicators and quotas.

Another exhibit from Kardex highlighted their FulfillX warehouse execution system, purpose-built to allow AutoStore systems to ramp up faster. It is capable of meeting or exceeding business cases in as little as six months to help companies realize the potential automated storage and retrieval system technology can offer.

Improving safety and security

Cybersecurity remains a major topic and focus of concern for manufacturers. In terms of visibility, it remains below the surface, but companies continue to worry about protecting their systems, their intellectual property and their workers.

“Most of us are not prepared for the attacks,” said David Bader, VP of business development, Eurotech, in his presentation “Designing for tomorrow’s cybersecurity challenges.”

He argued companies can develop a strong system by starting with these four steps: Be secure by design, develop zero trust security protocols, adhere to current cybersecurity standards and adopt a defense-in-depth approach.

Worker safety also remains a major concern as companies are trying to reduce workplace violations and OSHA fines. Knowing the standards and situation for a particular application can go a long way in reducing risk, according to Jenny Tuertscher, VP of technical safety for Fortress Safety.

In her presentation, “Risk Reduction Is Not Always About Changing Your Control System,” Tuertscher used an example of adding blades to a 50-year-old concrete mixer. These could not be safely changed without causing major issues and potential hazards. By knowing the standards and situation, they found a solution that not only kept the workers reasonably safe from harm, but also was cost-effective.

The future of automation, Automate

Automate has become more mobile and flexible since its last visit to McCormick. It stands to reason when the show returns in 2026 that will continue to be the case.

It’s the journey that matters and automation is going to keep evolving. As it does, people will remain the glue behind the scenes and will evolve along with the technology as we better realize our skills and knowledge with the newfound freedom gained from not having to do the heavy lifting.

Instead, people will use their minds and creativity to create an even better world.

Chris Vavra, senior editor, Control Engineering, WTWH Media LLC, [email protected].