Industrial Networking

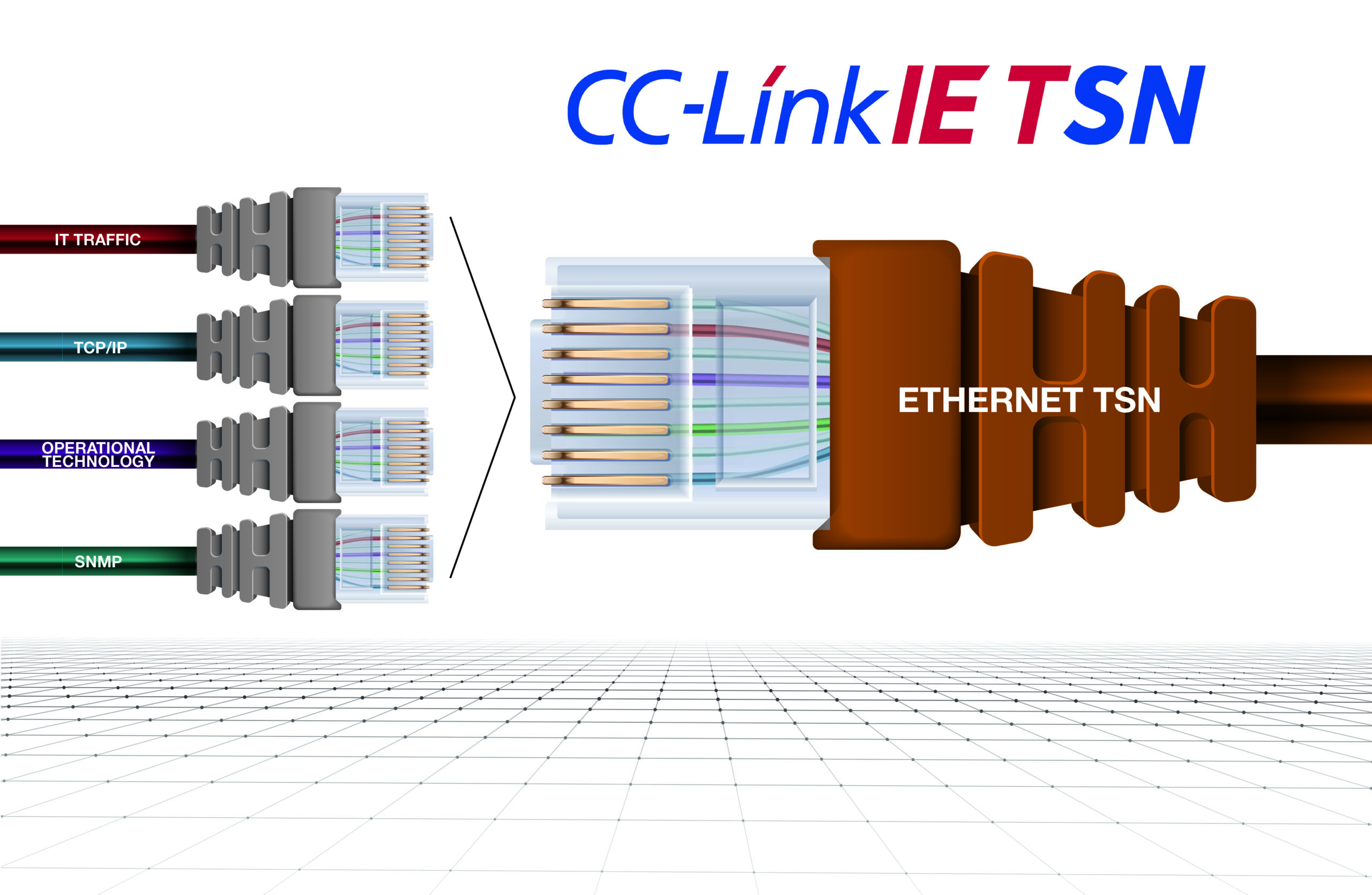

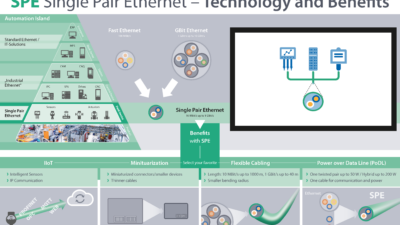

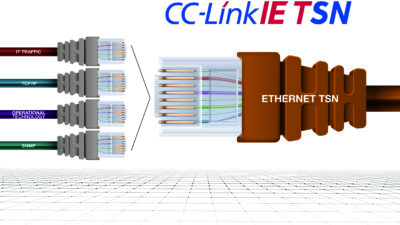

Industrial networking refers to the use of networking technologies and protocols to connect industrial devices and systems, such as sensors, controllers and other equipment, to facilitate communication and data exchange. Examples of industrial networking technologies include Ethernet, fieldbuses, device networks and various wireless networking technologies, using standards and/or proprietary physical designs and protocols.